Amino acid grafted glycidyl methacrylate (GMA)-divinyl benzene (DVB) copolymer chelate resin and preparation method and application

A technology of branching methacrylic acid and glycidyl ester, which is applied in the field of preparation of amino acid grafted GMA-DVB copolymer chelating resin, to achieve the effect of easy solid-liquid separation and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

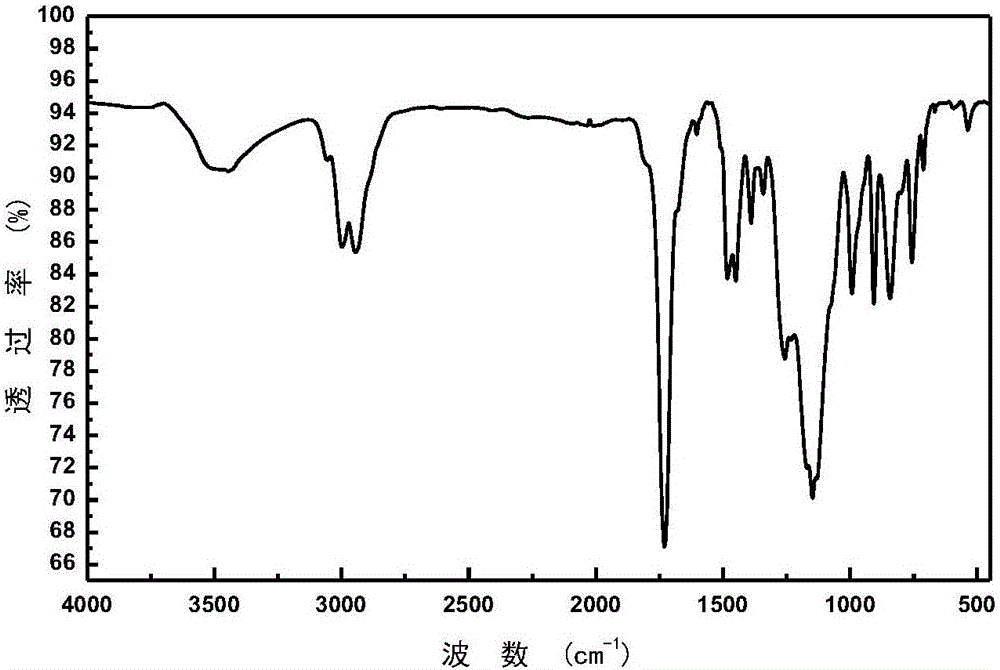

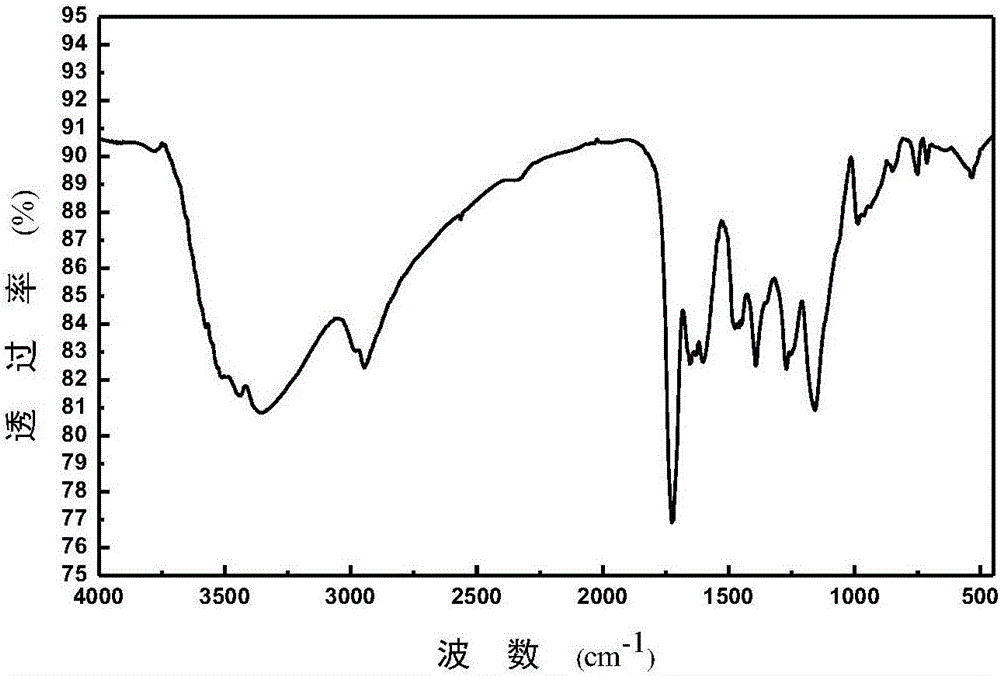

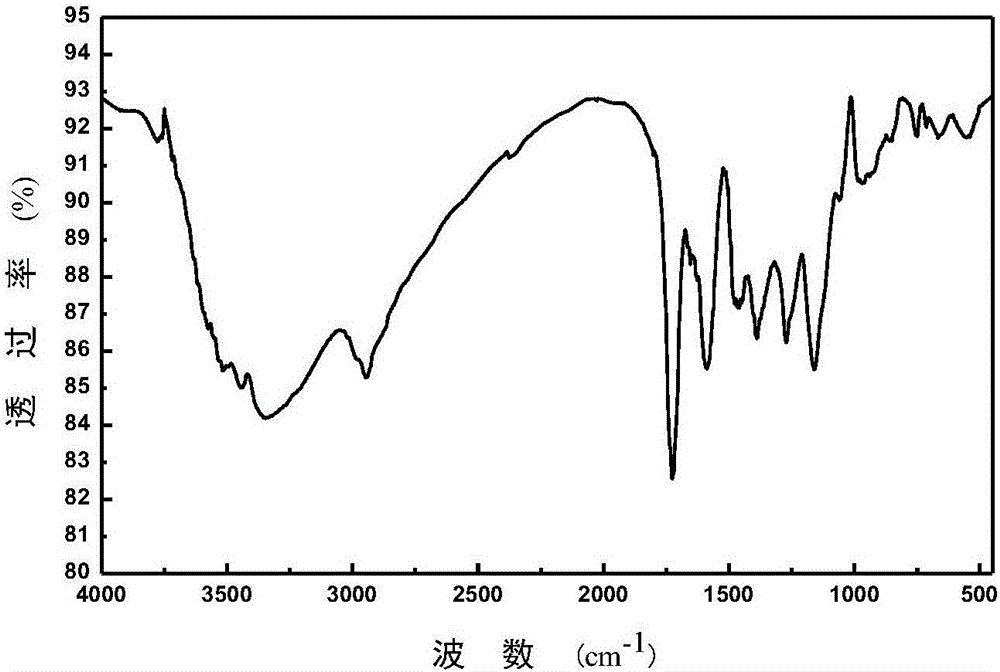

Image

Examples

specific Embodiment 1

[0033] (1) Add 0.125-0.75g of polyvinyl alcohol into a beaker filled with 10-40ml of distilled water, first swell in cold water at 10-30°C for 1-5h, then raise the temperature to 80-100°C for 1-3h, until Presents a transparent solution (I).

[0034] (2) In a 100ml reactor equipped with a reflux condenser and a heating and stirring device, add an aqueous solution (I) of polyvinyl alcohol, 2 to 6ml of glycidyl methacrylate monomer and 0.11 to 1.26g of divinylbenzene, After stirring to fully disperse the two phases, heat to raise the temperature of the reaction system to 60-80°C, and pass N 2 30 minutes.

[0035] (3) Add 1 to 5 ml of the mixed porogen dissolved with the initiator azobisisobutyronitrile (accounting for 0.5 to 3% of the mass of glycidyl methacrylate monomer) into the reaction system while blowing nitrogen gas, and mix to form The volume ratio of toluene and n-heptane in the pore agent is 2:1~5:1, and the N 2 Stir and react at a constant temperature of 60-80°C fo...

specific Embodiment 2

[0039] Add 0.5g of polyvinyl alcohol into a beaker filled with 25ml of distilled water, swell in cold water at 25°C for 1 hour, then raise the temperature to 90°C to accelerate dissolution, and keep it warm for 2 hours until a transparent solution appears. Add the prepared polyvinyl alcohol aqueous solution, 3ml glycidyl methacrylate and 0.52ml divinylbenzene into a 100ml reactor equipped with a reflux condenser and a heating and stirring device, stir to fully disperse the two phases, and heat in an oil bath to make The temperature of the reaction system was raised to 70°C, and N 2 30 minutes. The mixed porogen toluene and n-heptane mixed solution of dissolving 0.032g initiator azobisisobutyronitrile are added in the reaction system while logical nitrogen (in the mixed porogen, v 甲苯 : v 正庚烷 =4:1, the mixed porogen dosage is 60% of the monomer mass). in N 2 Stir and react at a constant temperature of 70°C for 3 hours under protection. After the reaction is completed, heat u...

specific Embodiment 3

[0042] The reaction steps and conditions are the same as those in Example 2. The amino acid used is L-aspartic acid in an amount of 3.727 g, which is added to 10 ml of an aqueous solution containing 2.250 g of NaOH. Finally, the GMA-DVB chelating resin grafted with L-aspartic acid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com