Modified silk fiber with high moisture absorbability and moisture retentivity and preparing method thereof

A silk fiber, high hygroscopic technology, applied in the field of textile materials, can solve the problem of limited water absorption, achieve excellent hygroscopicity, prevent loss and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

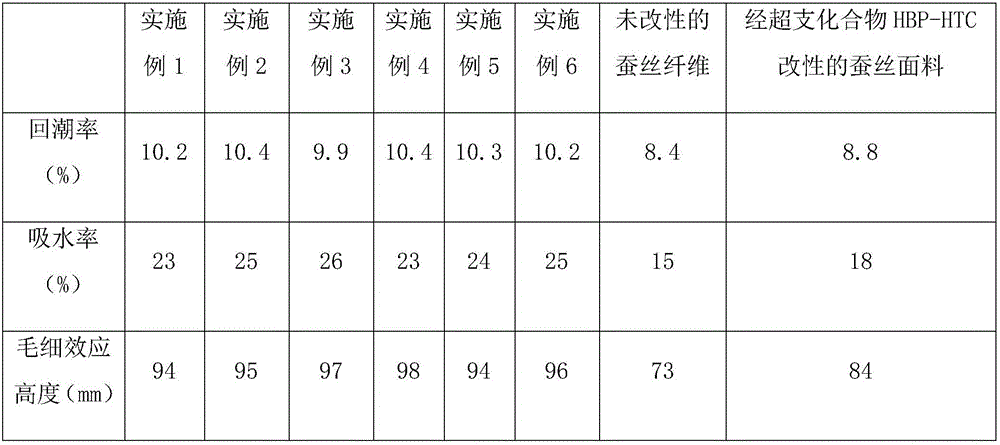

Examples

Embodiment 1

[0026] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 2%, and it is swelled at 70°C for 5 minutes, and then the swollen silk fiber is kneaded and carded to obtain a fibrillation degree of 20%. of silk fibers.

[0027] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 85% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 5 parts of molecular weight chitosan, 3 parts of sodium alginate, 2 parts of corn starch, 1 part of honeysuckle and 50 parts of deionized water.

[0028] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 25° C. to completely wet them, taken out, dried at 60° C., and then Immerse in the silk fibroin ...

Embodiment 2

[0030] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 4%, and it is swelled at 80°C for 15 minutes, and then the swollen silk fiber is rubbed and carded to obtain a fibrillation degree of 35%. of silk fibers.

[0031] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 95% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 15 parts of chitosan with molecular weight, 7 parts of sodium alginate, 8 parts of corn starch, 5 parts of honeysuckle and 80 parts of deionized water.

[0032] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 30° C. to completely wet them, taken out, dried at 70° C., and then Immerse in the silk f...

Embodiment 3

[0034] (1) After the silk is degummed, it is added to a calcium chloride solution with a concentration of 3%, and it is swelled at 75°C for 10 minutes, and then the swollen silk fiber is kneaded and carded to obtain a fibrillation degree of 25%. of silk fibers.

[0035] (2) In parts by weight, add sodium alginate solution, cornstarch and honeysuckle extract to the chitosan solution with a low molecular weight of 90% deacetylation degree, stir until mixed evenly, and form a moisture-absorbing and moisturizing finishing agent, wherein low 10 parts of chitosan with molecular weight, 5 parts of sodium alginate, 4 parts of corn starch, 2 parts of honeysuckle and 60 parts of deionized water.

[0036] (3) After the finely fibrillated silk fibers prepared in step (1) are dried at room temperature, they are immersed in the moisture-absorbing and moisturizing finishing agent prepared in step (2) at 27° C. to completely wet them, taken out, dried at 65° C., and then Immerse in the silk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com