Nitrogen-doped graphene/cobalt-iron hydrotalcite bifunctional oxygen catalyst and its preparation method and application

A nitrogen-doped graphene, oxygen catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of low price, good catalytic activity, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (a) Preparation of CoFe-LDO hybrid

[0035] Dissolve cobalt chloride hexahydrate and ferric chloride hexahydrate in ultrapure water at a certain molar ratio, so that the total concentration of metal ions is 0.215mol / L, stir to dissolve completely, and then drop in 1.5mol / L NaOH at a constant speed, Until the pH=8, the mixed solution was transferred into a reaction kettle and reacted at 130°C for 24 hours. After the reaction solution was centrifuged, washed three times with deionized water and ethanol respectively, dried and ground, and calcined at 500°C for 5 hours in an air atmosphere, the obtained product That is CoFe-LDO hybrid;

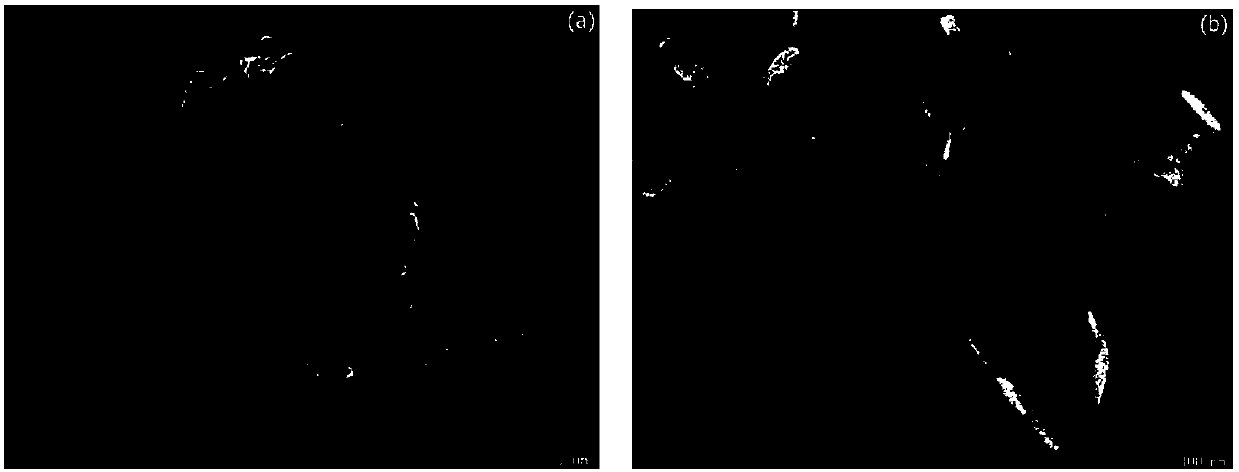

[0036] (b) Preparation of GO / LDH complex

[0037] Disperse a certain amount of GO in ultrapure water, ultrasonically disperse for 4 hours, and centrifuge at 5000rpm for 10min to remove unstripped GO, so that the final concentration is 1.0mg / mL, pipette 50mL of the solution, and slowly add 50mg of the step ( The CoFe-LDO hybrid obtained in...

Embodiment 2

[0041] (a) Preparation of CoFe-LDO hybrid

[0042] Prepared according to the method and conditions of step (a) in Example 1;

[0043] (b) Preparation of GO / LDH complex

[0044] Disperse a certain amount of GO in ultrapure water, ultrasonically disperse for 4 hours, and centrifuge at 5000rpm for 10min to remove unstripped GO, so that the final concentration is 3.0mg / mL, pipette 50mL of the solution, and slowly add 50mg of the step ( The CoFe-LDO hybrid obtained in a) was stirred at room temperature for 12 hours, and then centrifuged at 3000rpm for 10 minutes, and the resulting precipitate was the GO / LDH complex;

[0045] (c) Preparation of NG / LDH oxygen catalyst

[0046] Prepared according to the method and conditions of step (c) in Example 1, its average particle diameter is 136nm, and the specific surface area is 142.38m 2 / g.

Embodiment 3

[0048] (a) Preparation of CoFe-LDO hybrid

[0049] Prepared according to the method and conditions of step (a) in Example 1;

[0050] (b) Preparation of GO / LDH complex

[0051] Disperse a certain amount of GO in ultrapure water, ultrasonically disperse for 4 hours, and centrifuge at 5000rpm for 10min to remove unstripped GO, so that the final concentration is 6.0mg / mL, pipette 50mL of the solution, and slowly add 50mg of the step ( The CoFe-LDO hybrid obtained in a) was stirred at room temperature for 12 hours, and then centrifuged at 3000rpm for 10 minutes, and the resulting precipitate was the GO / LDH complex;

[0052] (c) Preparation of NG / LDH oxygen catalyst

[0053] Prepared according to the method and conditions of step (c) in Example 1, its average particle diameter is 125nm, and the specific surface area is 168.63m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com