Child edible calcium, ferrum and zinc chewable tablets

A chewable tablet, calcium, iron and zinc technology, applied in the field of health food and its preparation, can solve the problems of increasing the risk of caries in children and failing to meet people's living needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

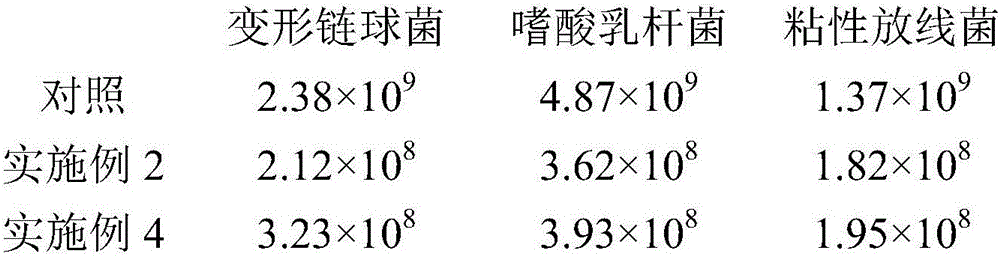

Examples

Embodiment 1

[0055] A calcium-iron-zinc chewable tablet for children, including isomaltulose, whey protein powder, milk mineral salt, zinc-enriched yeast, iron pyrophosphate and magnesium stearate.

[0056] As a preferred implementation of the above examples, the components of the above-mentioned children's edible calcium, iron and zinc chewable tablets are by weight: 45-55 parts of isomaltulose, 13-30 parts of whey protein powder, 5-5 parts of milk mineral salt 10 parts, 2-6 parts of zinc-rich yeast, 0.2-1 part of iron pyrophosphate, 1-2 parts of magnesium stearate.

[0057] As a preferred implementation of the above examples, vitamin C, kiwi fruit powder, peach powder, orange powder, carrot powder, cucumber powder, broccoli powder, and celery powder are also included.

[0058] As a preferred embodiment of the above example, according to its weight ratio, 0.1-0.3 parts of vitamin C, 4.5-5.5 parts of kiwi fruit powder, 0.2-1 part of peach powder, 0.2-0.8 part of orange powder, and 2-5 part...

Embodiment 2

[0060] An edible iron calcium zinc chewable tablet for children. According to its weight ratio, each component is: 50 parts of isomaltulose, 26.4 parts of whey protein powder, 8 parts of milk mineral salt, 3.5 parts of zinc-rich yeast, iron pyrophosphate 0.4 parts, 1.5 parts of magnesium stearate.

Embodiment 3

[0062] A preparation method for children's edible iron-calcium-zinc chewable tablets, comprising the following steps:

[0063] S1: Grinding of raw materials: Grinding isomaltulose, whey protein powder, milk mineral salt, zinc-enriched yeast, iron pyrophosphate and magnesium stearate with a grinder, and passing through a 60-mesh sieve;

[0064] S2: Granulation and drying: Accurately weigh isomaltulose, whey protein powder and milk mineral salt according to the weight ratio and mix well, then add to boiling granulator, drying temperature is 65-70°C, drying time is 55-65min, 16-mesh sieve for granulation, the obtained granule A;

[0065] S3: Weighing other raw and auxiliary materials: accurately weigh zinc-rich yeast, iron pyrophosphate and magnesium stearate according to the weight ratio;

[0066] S4: Mixing: add the granulated and dried granule A in S2 and the raw and auxiliary materials weighed in S3 into the tank mixer, stir for 15-30min, make it fully mixed, and obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com