Process for recovery of sodium chloride electrolysis industrial exhaust

A technology of electrolysis industry and tail gas recovery, applied in the direction of alkali metal chlorides, chemical instruments and methods, separation methods, etc., can solve the problems of secondary pollution, unavoidable natural decomposition of sodium hypochlorite, etc., achieve efficient absorption and realize harmlessness The effect of high decomposition and catalytic decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

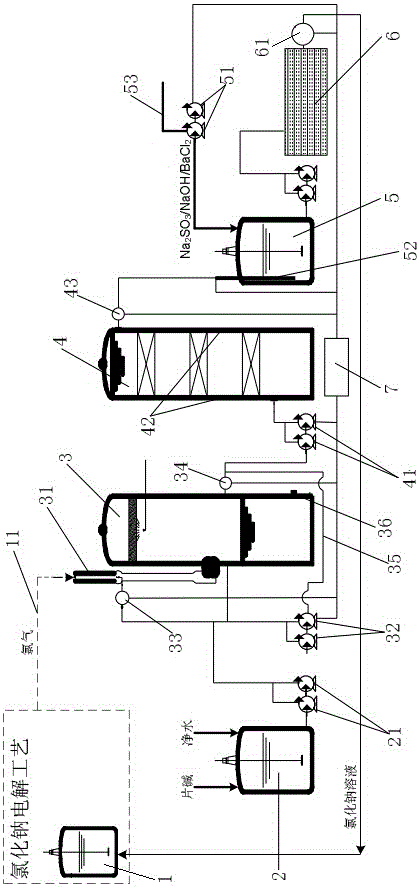

[0029] see figure 1 , adopting capacity is the tank of 20 cubic meters as alkali distribution tank 2, prepares lye as absorption liquid; Dynamic wave absorption device 31 is installed on the side of absorption tower 3, and is connected with lye output pump 21 and circulation pump 32, and 1# mass flow meter 33 and 2# mass flow meter 34 are respectively installed at the liquid inlet and outlet of absorption tower; #Mass flow meter 43, heating device 42 is installed inside; Selecting capacity is the tank of 10 cubic meters as regulating tank 5, and measuring equipment 52 is set inside it, feeding pipe 53 is set at its top and feeds by feeding pump 51 control feeding; Filter The device 6 receives the solution from the regulating tank 5. After the filtration is completed, the filtrate is tested by the online particle detector 61 and then transported to the NaCl electrolytic tank 1 of the NaCl electrolysis process. All testing equipment (including 1# mass flowmeter 33, 2# mass flow...

Embodiment 2

[0032] see figure 1 The steps of the sodium chloride electrolysis industrial tail gas recovery and treatment process in the present embodiment are as follows: the sodium chloride electrolysis industrial tail gas is transported to the dynamic wave absorption device 31 through the pipeline, and the sodium hydroxide solution is transported to the dynamic wave absorption device 31 through the pipeline , under the action of the dynamic wave absorbing device 31, the sodium hydroxide solution is sprayed into foam and fully contacted with the tail gas of the sodium chloride electrolysis industry, so that the chlorine in the tail gas of the sodium chloride electrolysis industry is fully absorbed by the foamy sodium hydroxide solution. Absorb to form the absorption liquid containing sodium hypochlorite, then the absorption liquid enters the absorption tower 3, and detects the concentration of the salt sodium hypochlorite in the absorption liquid in the absorption tower 3 in real time, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com