Method for preparing functional group modified alginate-graphene dual-network nano-composite gel beads

An alginate and nanocomposite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as less double network gel, achieve easy promotion, hydroxyl and carboxyl functional groups The effect of increasing the content and enhancing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

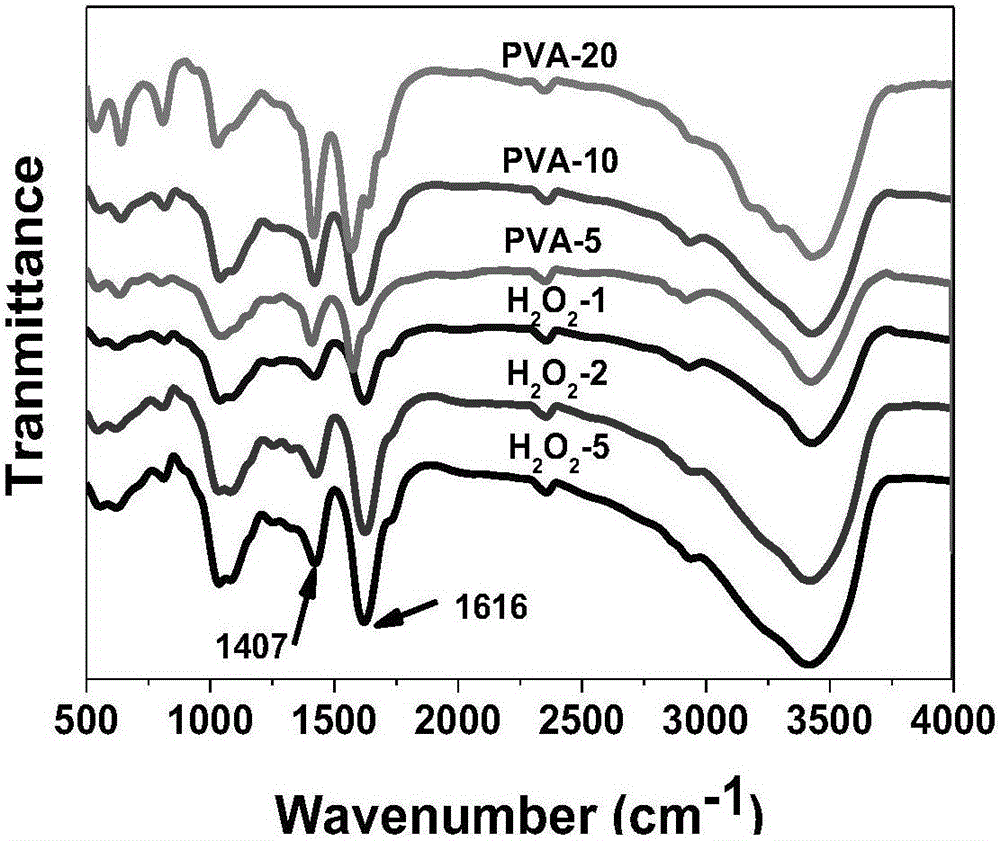

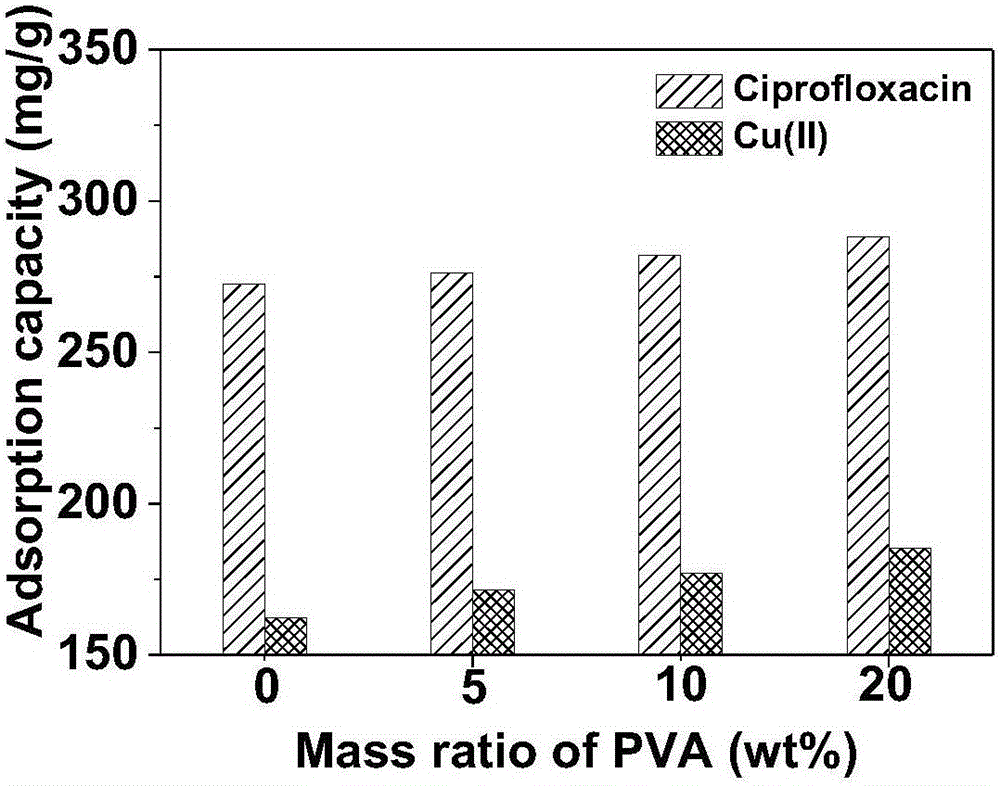

[0024] Step 1, take three beakers, add 40mg graphene oxide, 20mg sodium alginate and 20mL distilled water, respectively add 5, 10 and 20mg polyvinyl alcohol to the three beakers, ultrasonically 6h to, mechanically stir for 1h to form a uniform solution . Take another three beakers, all equipped with 20mL of 10mg / mL CaCl 2 solution, drop the graphene oxide / sodium alginate / polyvinyl alcohol solution into CaCl with a peristaltic pump 2 solution to obtain hydroxylated single network gel spheres.

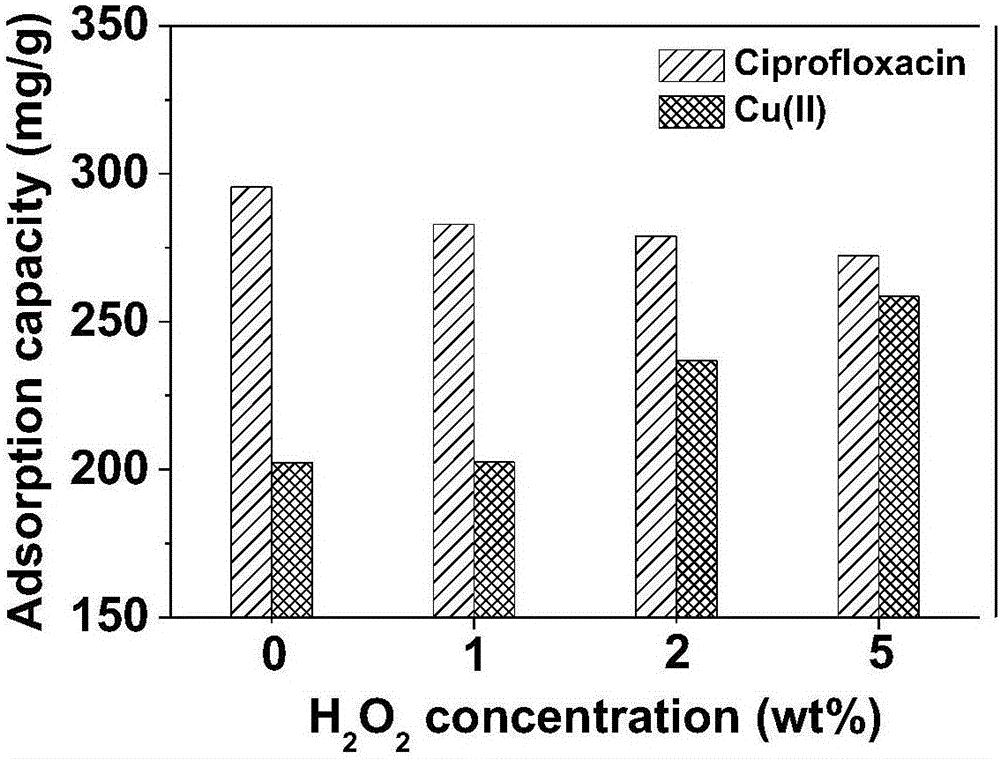

[0025] Step 2, take another three beakers, weigh and dissolve ascorbic acid with a mass ratio of 1:1 to graphene oxide, put the hydroxylated single-network gel spheres into the ascorbic acid solution and heat for 8h to obtain hydroxylated double-network nanocomposite gels. Gumball. Soak the obtained hydroxylated double network in 100 mL of 1% FeCl 3 In the solution, configure 100mL H of a certain concentration 2 O 2 solutions (1, 2 and 5% by mass), will soak the FeCl with the doubl...

Embodiment 2

[0030] Take three beakers, add 80 mg of graphene oxide, 20 mg of sodium alginate and 20 mL of distilled water, respectively, add 5, 10 and 20 mg of polyvinyl alcohol to the three beakers, ultrasonicate for 6 hours, and mechanically stir for 1 hour to form a uniform solution. Take another three beakers, all equipped with 20mL of 10mg / mL BaCl 2 solution, drop the graphene oxide / sodium alginate / polyvinyl alcohol solution into CaCl with a peristaltic pump 2 solution to obtain hydroxylated single network gel spheres. Take another three beakers, weigh and dissolve ascorbic acid with a mass ratio of 1:1 to graphene oxide, put the hydroxylated single-network gel spheres in the ascorbic acid solution and heat for 8 hours to obtain the hydroxylated double-network nanocomposite gel spheres. Soak the obtained hydroxylated double network in 100 mL of 1% FeCl 3 In the solution, configure 100mL H of a certain concentration 2 O 2 solutions (1, 2 and 5% by mass), will soak the FeCl with th...

Embodiment 3

[0032] Take three beakers, add 40 mg of graphene oxide, 20 mg of sodium alginate and 20 mL of distilled water, respectively, add 5, 10 and 20 mg of polyvinyl alcohol to the three beakers, ultrasonicate for 6 hours, and mechanically stir for 1 hour to form a uniform solution. Take another three beakers, all equipped with 20mL of 10mg / mL BaCl 2 solution, drop the graphene oxide / sodium alginate / polyvinyl alcohol solution into CaCl with a peristaltic pump 2 solution to obtain hydroxylated single network gel spheres. Take another three beakers, weigh and dissolve sodium borohydride with a mass ratio of 1:1 to graphene oxide, put the hydroxylated single-network gel spheres into the sodium borohydride solution and heat for 8 hours to obtain hydroxylated double-network nanocomposite Gel balls. Soak the obtained hydroxylated double network in 100 mL of 1% FeCl 3 In the solution, configure 100mL H of a certain concentration 2 O 2 solutions (1, 2 and 5% by mass), will soak the FeCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com