Method of producing carbonates and recycling energy by cyclically capturing and mineralizing CO2

A technology for recovering energy and carbonate, applied in carbonate preparations, calcium carbonate/strontium/barium, chemical industry, etc., can solve resource waste, high-alkaline calcium-containing wastewater from calcium carbide residue cannot be cleaned and utilized, and affect normal production, etc. problem, to achieve significant results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put the calcium-containing waste slag in the slurry tank, add water and stir until all the soluble substances in it are dissolved, and control the temperature at 30°C to obtain a calcium-containing alkaline aqueous solution with a pH value > 12; the calcium-containing waste slag is waste calcium carbide slag from the PVC industry;

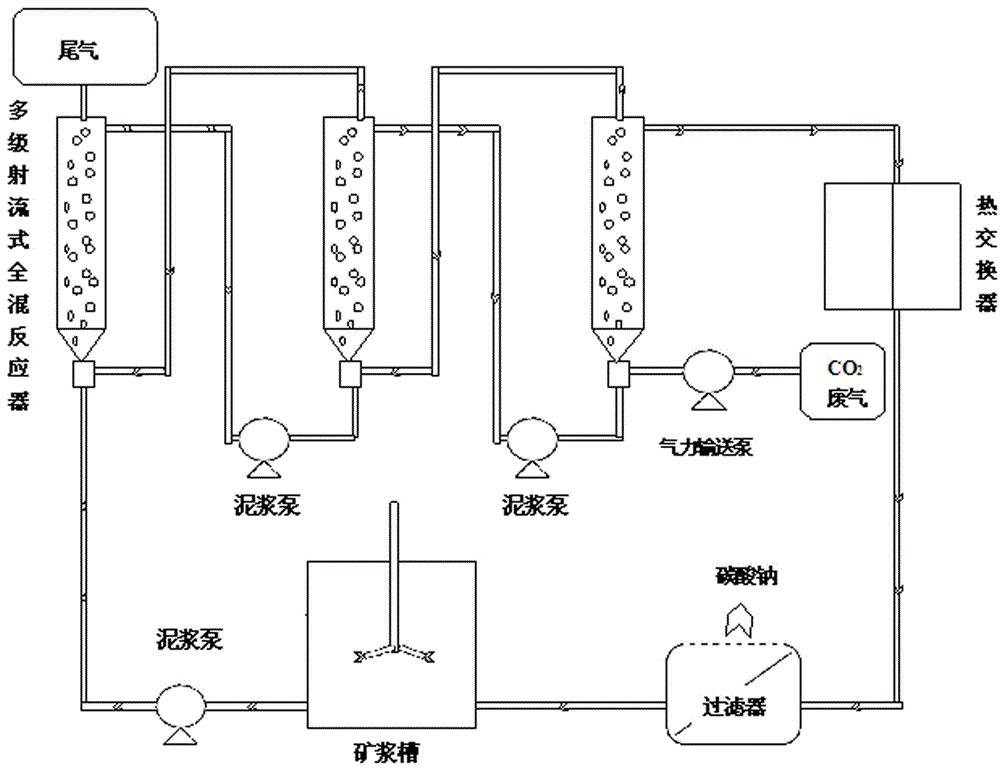

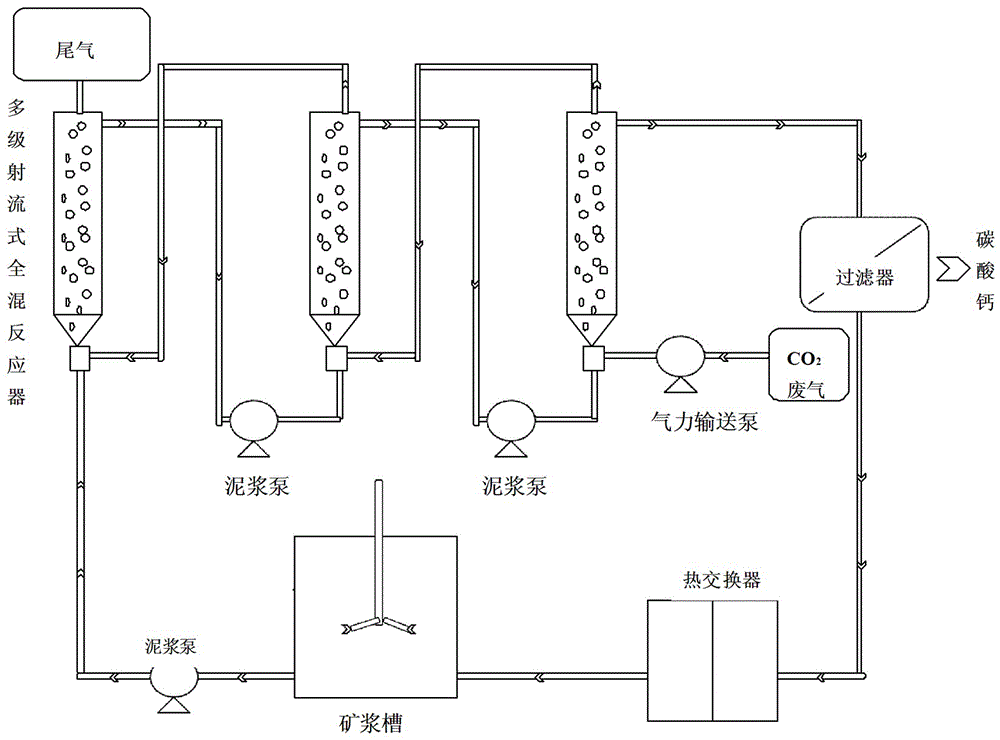

[0031] The calcium-containing alkaline aqueous solution is sent into the multi-stage jet-type fully mixed reactor through the booster pump, and the injection pressure is 0.5MPa; at the same time, the CO 2 The flue gas is fed into the multi-stage jet-type fully mixed reactor, and the CO 2 The injection pressure of the flue gas is 0.2MPa; the alkaline aqueous solution containing calcium and CO2 The flue gas flows in the reverse direction in the multi-stage jet type fully mixed reactor, and the gas-liquid two-phase mineralization absorption reaction is carried out to realize the CO 2 capture mineralization;

[0032] Calcium-containing alkaline...

Embodiment 2

[0038] Put the sodium-containing waste residue in the slurry tank, add water and stir until all the soluble substances in it are dissolved, and at the same time control the temperature at 30°C to obtain a sodium-containing alkaline aqueous solution with a pH value > 14; the sodium-containing waste residue is red mud from the alumina industry;

[0039] The sodium-containing alkaline aqueous solution is sent into the multi-stage jet-type fully mixed reactor through a booster pump, and the injection pressure of the sodium-containing alkaline aqueous solution is 0.5 MPa; at the same time, the CO 2 The flue gas is fed into the multi-stage jet-type fully mixed reactor, and the CO 2 The injection pressure of flue gas is 0.2MPa; calcium-containing alkaline aqueous solution or sodium-containing alkaline aqueous solution and CO 2 The flue gas flows in the reverse direction in the multi-stage jet type fully mixed reactor, and the gas-liquid two-phase mineralization absorption reaction is...

Embodiment 3

[0046] The calcium-containing alkaline wastewater of the iron and steel industry is used as a calcium-containing alkaline aqueous solution with a pH value > 12;

[0047] The calcium-containing alkaline aqueous solution is sent into the multi-stage jet-type fully mixed reactor through a booster pump, and the injection pressure of the calcium-containing alkaline aqueous solution is 0.5 MPa; at the same time, the CO 2 The flue gas is fed into the multi-stage jet-type fully mixed reactor, and the CO 2 The injection pressure of the flue gas is 0.2MPa; the alkaline aqueous solution containing calcium and CO 2 The flue gas flows in the reverse direction in the multi-stage jet type fully mixed reactor, and the gas-liquid two-phase mineralization absorption reaction is carried out to realize the CO 2 capture mineralization;

[0048] Calcium-containing alkaline aqueous solution and CO 2 The reaction formula on which the flue gas intake is based is:

[0049] CO 2 + Ca 2+ +H 2 O=Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com