Ester-type high-early-strength water reducing agent and preparation method thereof

An early-strength, water-reducing agent technology, applied in the field of building materials, can solve the problems of poor adaptability and insignificant effect of early-strength water-reducing agent, and achieve good compactness, strong steric hindrance and dispersion ability, and reduce capillary pores. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing an ester early-strength water reducer is also described, which is characterized in that it includes the following steps:

[0037] a) Esterification reaction

[0038] According to the above parts by weight, polyethylene glycol, catalyst, polymerization inhibitor, and water-carrying agent are added to the reaction kettle, and the temperature is adjusted to 60 ° C. After the reactants are completely dissolved, add acrylic acid or its derivatives, and heat up to 90 ° C. ℃, react for 1-5 hours, and then remove the water-carrying agent. Add the product into a saturated NaCl solution, adjust the pH to neutral after being dissolved, then add ethyl acetate at room temperature, and separate the aqueous layer with only the monoester. Ethyl acetate was added to the aqueous layer and heated to 50°C. After the monoester enters the ethyl acetate layer, add a mixed solution of saturated NaCl and saturated Na2CO3 with a volume ratio of 3:1 at room temperature, r...

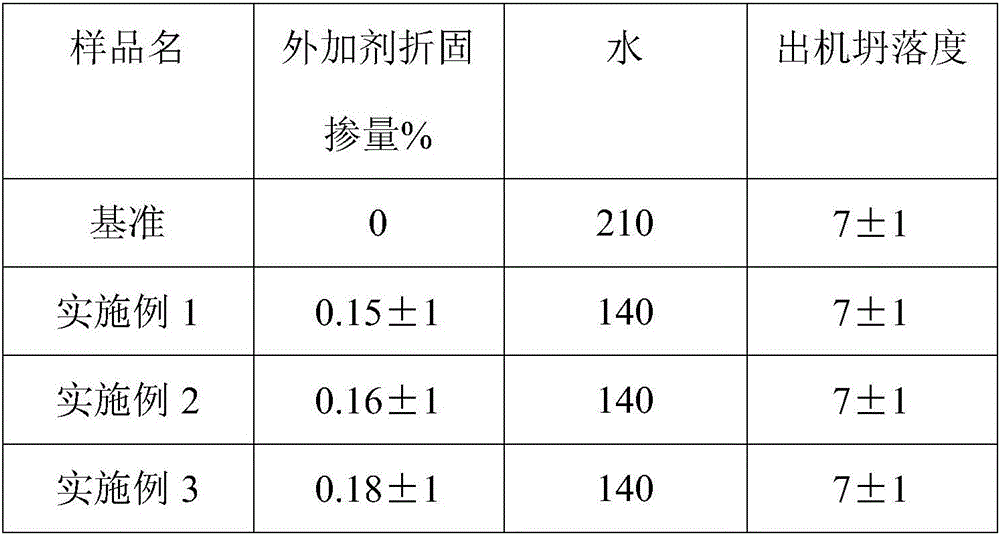

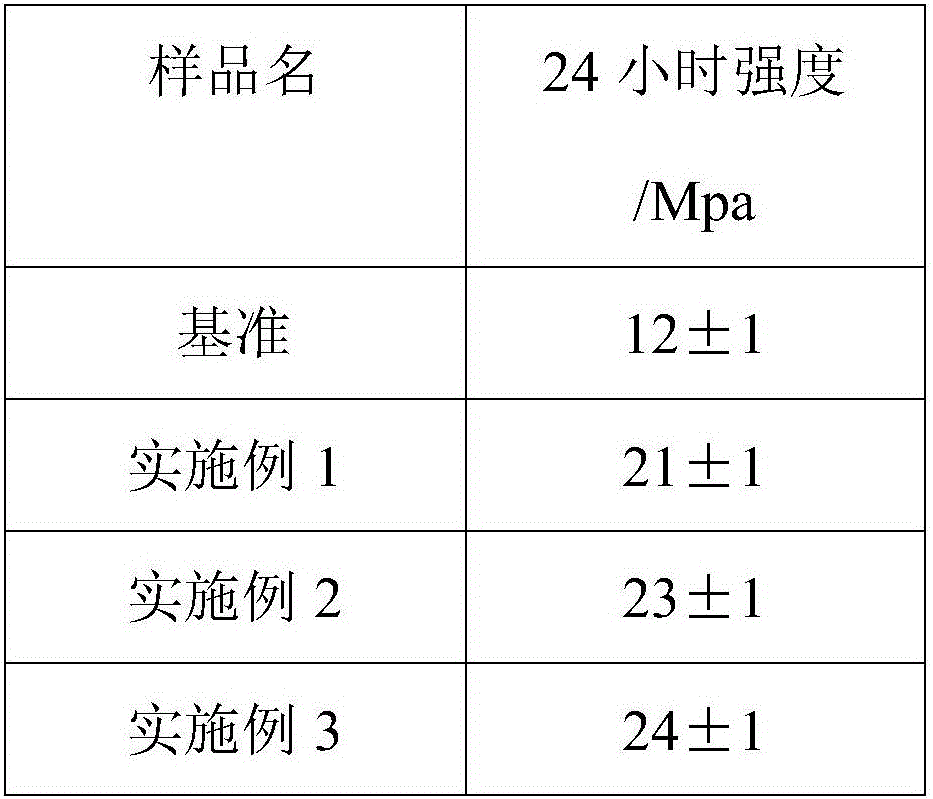

Embodiment 1

[0050](1) Esterification reaction: Add 80 parts of polyethylene glycol (molecular weight: 6000), 0.2 part of hydroquinone, 0.3 part of p-toluenesulfonic acid, 40 parts of cyclohexane into a 500ml three-necked flask, and stir with a magnetic force And heat up to 60 ° C, until the dissolution is complete, add 1.2 parts of acrylic acid (or a certain number of methyl acrylate, sodium acrylate, lithium acrylate, methacrylic acid, methyl methacrylate, sodium methacrylate, lithium methacrylate One or more of them), after reacting for 1 to 5 hours, pour the reactant into a spherical flask to distill off cyclohexane under reduced pressure, then add 200 parts of saturated sodium chloride solution, and after the dissolution, use saturated Adjust the pH value to about 8 with sodium carbonate, add 200ml of ethyl acetate under normal temperature conditions, introduce it into a separatory funnel, extract the monoester in the water layer layer by layer, pour it into a spherical flask and disti...

Embodiment 2

[0053] (1) Esterification reaction: Add 90 parts of polyethylene glycol (molecular weight: 8000), 0.3 part of p-toluenesulfonic acid, 0.2 part of hydroquinone, 40 parts of cyclohexane into a 500ml three-necked flask, and stir with a magnetic force And heat up to 60 ° C, until the dissolution is complete, add 1 part of acrylic acid (or a certain number of methyl acrylate, sodium acrylate, lithium acrylate, methacrylic acid, methyl methacrylate, sodium methacrylate, lithium methacrylate One or more of them), after reacting for 1 to 5 hours, pour the reactant into a spherical flask to distill off cyclohexane under reduced pressure, then add 200 parts of saturated sodium chloride solution, and after the dissolution, use saturated Adjust the pH value to about 8 with sodium carbonate, add 200ml of ethyl acetate under normal temperature conditions, introduce it into a separatory funnel, extract the monoester in the water layer layer by layer, pour it into a spherical flask and distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com