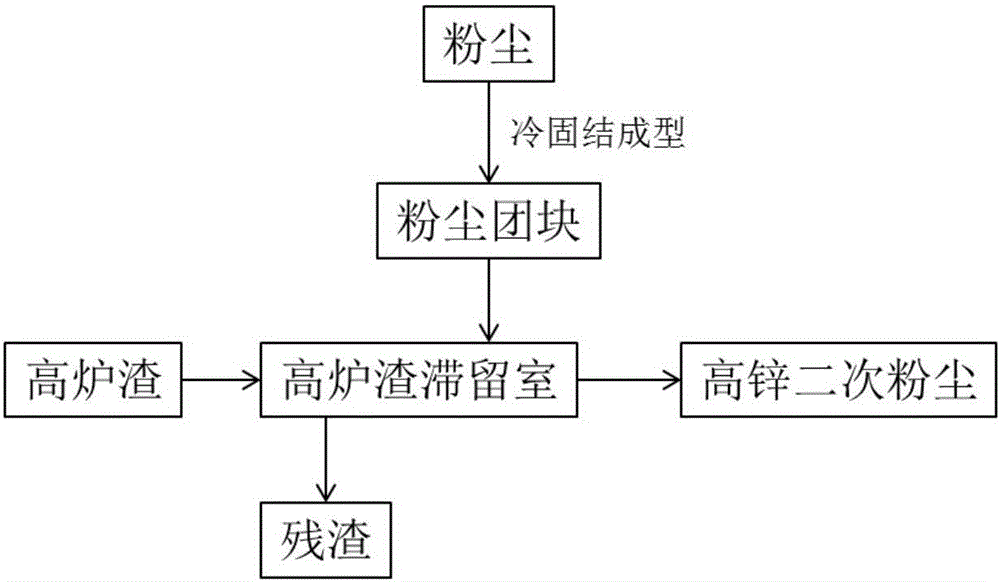

Method for recovering and treating zinc-containing dust through blast furnace slag sensible heat

A sensible heat recovery and blast furnace slag technology, applied in waste heat treatment, recycling technology, furnace and other directions, can solve the problems of waste of calorific value, waste of water resources, low thermal efficiency, etc., and achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

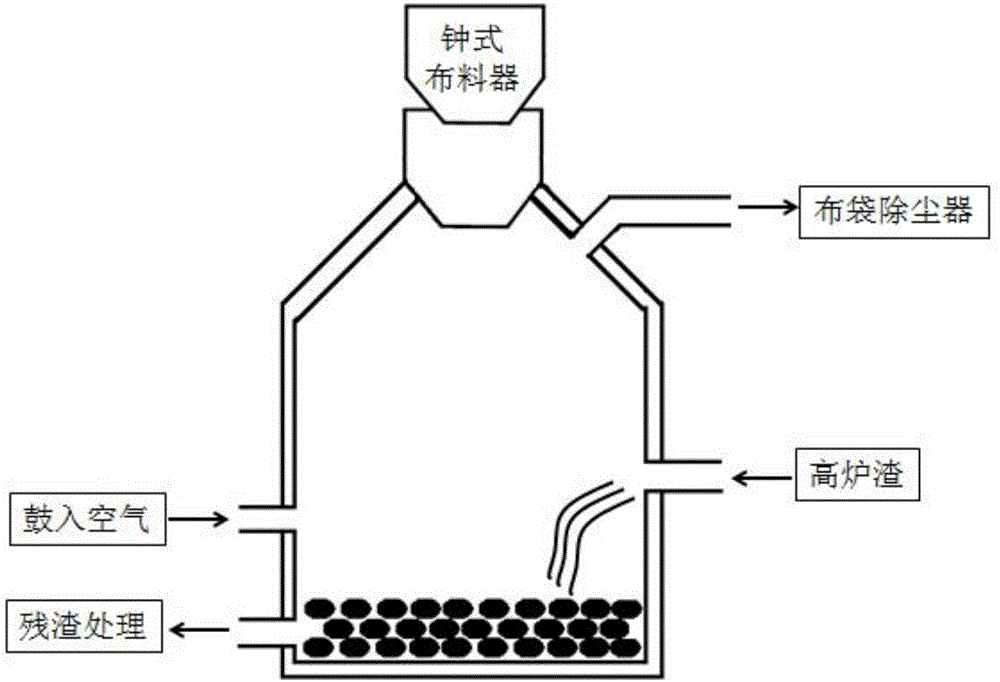

[0018] A blast furnace dust removal ash and converter sludge are selected as raw materials. The blast furnace dust removal composition is Fe: 35%, Zn: 10%, Pb: 3%, C: 20%, and the composition of converter sludge is: Fe: 55% , Zn: 1%, H 2 O: 30%. Lime is used as flux. According to the ratio of blast furnace dust: converter sludge: quicklime: cement: water is about 40:45:2:5:8, mix well and press into blocks under a pressure of not less than 20MPa, at a temperature of 20 ~ 30 ℃, humidity ≥ 95% environment for curing for 72 hours, after the curing is completed, send it to the stockyard for stacking. This method can make full use of the carbon in the dust removal dust of the blast furnace, does not need to add additional reducing agent, and can reduce the amount of flux added; at the same time, the water in the converter sludge can be used to reduce the amount of water added.

[0019] The cured briquettes are sent to the top silo of the slag retention chamber, and fed into the ...

Embodiment approach 2

[0021] Choose a kind of electric furnace dust as raw material, its composition is Fe: 35%, Zn: 15%, Pb: 3%; choose coke powder as reducing agent, its fixed carbon content is about 85.5%, ash content is about 12.5%, volatile The content is about 2%; silica powder is used as the flux, and its SiO 2 The content is about 98%; cement is used as the binder. Add coke powder, silica powder, cement and water according to the ratio of electric furnace dust: coke powder: silica powder: cement: water is about 75:10:5:5:5, mix well and under the pressure of not less than 20MPa Pressed into blocks, cured for 72 hours in an environment with a temperature of 20-30°C and a humidity of ≥95%, and sent to the stockyard for storage after the curing is completed.

[0022] The ash agglomerates from electric furnace dedusting are sent to the top silo of the slag retention chamber, and fed into the slag retention chamber through the material bell for reaction. The subsequent smelting process is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com