Manganese tin oxide based transparent conducting oxide and transparent conductive film and method for fabricating transparent conductive film using the same

一种透明导电膜、锡氧化物的技术,应用在氧化物导体、氧化锰/氢氧化锰、绝缘载体上的导电层等方向,能够解决金属层不能均匀蒸镀、表面粗糙度大、电阻增加等问题,达到稳定电特性及光学特性、低费用、优秀电特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

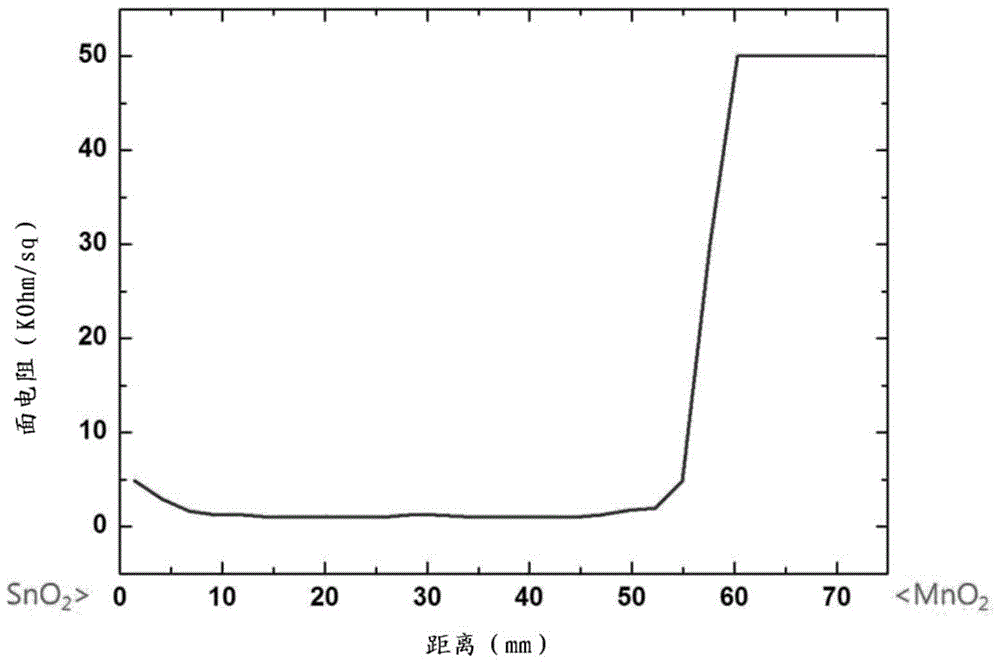

[0040] Example 1: Determination of optimal composition by continuous composition diffusion method

[0041] A glass substrate of 75 mm × 15 mm is located in an off-axis continuos compositions-spread sputtering device (off-axis continuos compositions-spread sputtering device) in which two sputtering guns (sputter guns) are arranged in a 90-degree manner. 2 inches of SnO are installed in the shooting gun 2 target and MnO 2 target. Use rotary pumps and turbomolecular pumps to form 2×10 -6 After a high vacuum atmosphere of about Torr, argon (Ar) gas is injected, and sputtering is performed at a pressure of 45 mtorr. At this time, SnO 2 Target with 40W power, MnO 2 The targets were each sputtered at a power of 10 W for 1 hour, and pre-sputtering was performed for 15 minutes before the thin film was deposited.

[0042] A thin film layer is formed on a glass substrate by sputtering, with SnO 2 target and MnO 2 target is used to form a Mn x sn 1-x MnO with continuous composit...

Embodiment 2

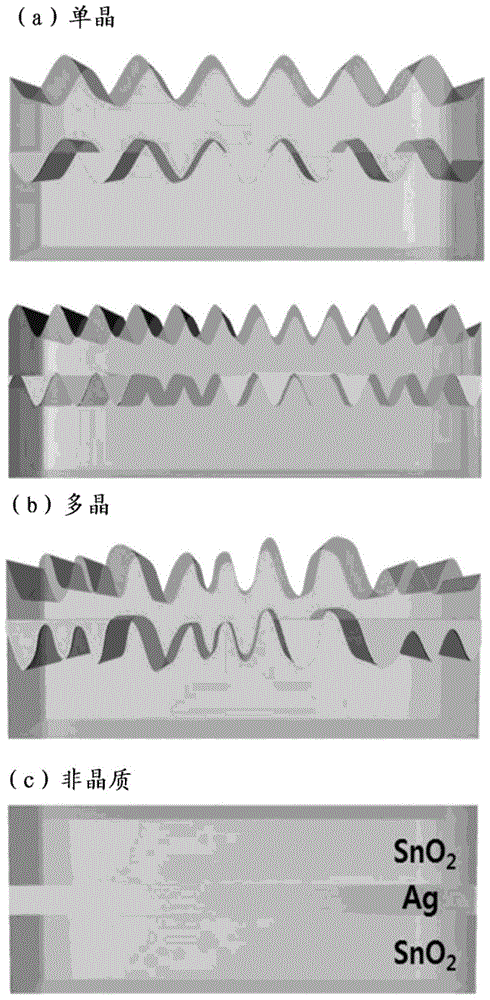

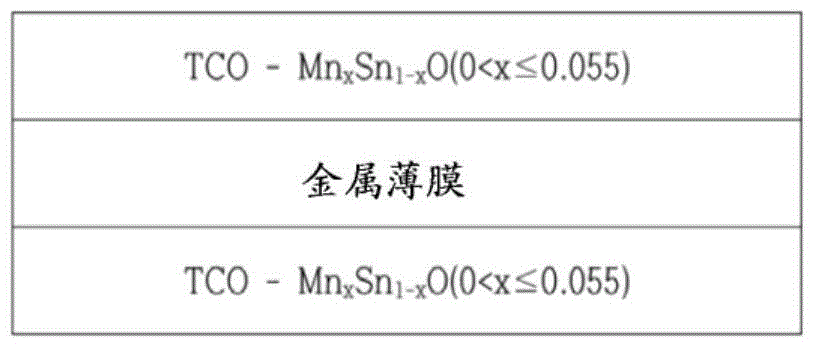

[0046] Embodiment 2: Evaporation and characteristics of multilayer transparent conductive film

[0047] On the glass substrate, transparent conductive oxide (TCO), metal thin film and transparent conductive oxide (TCO) are sequentially evaporated. The transparent conductive oxide is SnO doped with Mn 2 , The metal thin film is Ag. That is, forming Mn-doped SnO on a glass substrate 2 / Ag / Mn doped SnO 2 The multilayer transparent conductive film with the structure is vapor-deposited using the sputtering method at room temperature.

[0048] For Mn-doped SnO 2 , using a target pair of SnO containing 2.59% Mn 2 For comparison, SnO containing 2.59% Mn was vapor-deposited 2 and SnO 2 , to form SnO doped with 2.59wt% Mn 2 / Ag / SnO doped with 2.59wt% Mn 2 , SnO doped with 10wt% Mn 2 / Ag / SnO doped with 10wt% Mn 2 and SnO 2 / Ag / SnO 2 Three types of multilayer transparent conductive films.

[0049] Using an on-axis sputtering apparatus, vapor deposition was performed under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com