Manufacturing method for practical multi-core MgB2 composite superconductive wire rods

A technology of superconducting wires and wires, which is applied in the usage of superconducting elements, cable/conductor manufacturing, superconducting devices, etc., which can solve the problems of increasing the cost of wires, complicated preparation process, and expensive raw materials, etc., to achieve the improvement of superconducting performance , Improve thermal connectivity and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

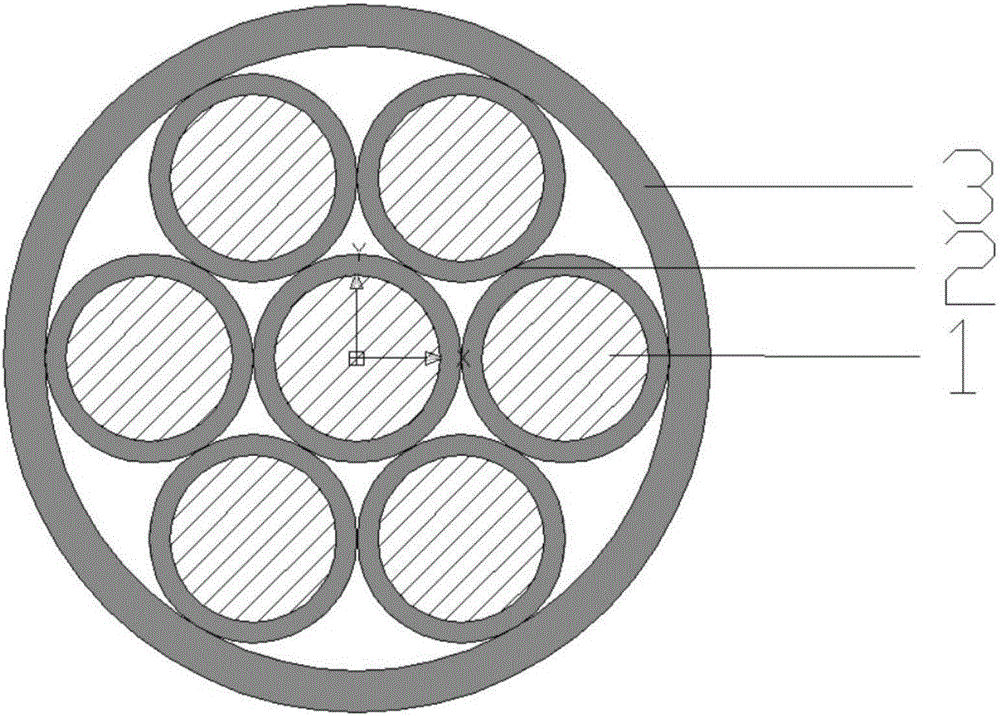

[0033] 7-core MgB 2 Preparation of superconducting materials:

[0034]The first step: under the protective environment of argon (volume percentage is 99.999%, the balance is air), atomized magnesium powder (purity is 99.5%, average particle diameter is 25 μm), amorphous boron powder (purity is 98%, with an average particle size of 0.53 μm), weighed according to the atomic ratio Mg:B=1.1:2, mixed and ball milled. The total time of ball milling is 3 hours, and the ball mill stops running for 5 minutes every 30 minutes to prevent the reaction between magnesium powder and boron powder caused by overheating of the powder.

[0035] The second step: the precursor powder described in the first step is loaded into the Fe metal tube with one end closed and pickled to obtain a filled metal tube. The pickling treatment is pickling with a mixture of concentrated hydrochloric acid and water, then washing the residual acid solution with water, then rinsing with absolute ethanol, and placin...

Embodiment 2

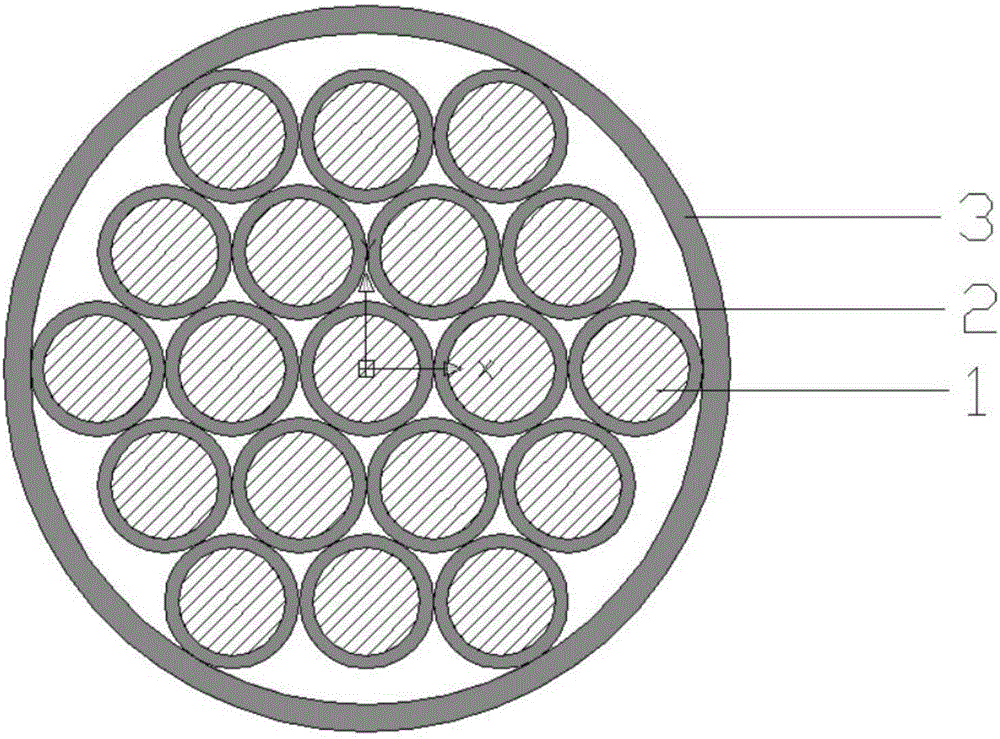

[0040] 19-core MgB 2 Preparation of superconducting materials:

[0041] The first step: under the protective environment of argon (volume percentage is 99.999%, the balance is air), atomized magnesium powder (purity is 99.5%, average particle diameter is 25 μm), amorphous boron powder (purity is 98%, with an average particle size of 0.53 μm), weighed according to the atomic ratio Mg:B=1.3:2, mixed and ball milled. The total time of ball milling is 3 hours, and the ball mill stops running for 5 minutes every 30 minutes to prevent the reaction between magnesium powder and boron powder caused by overheating of the powder.

[0042] The second step: the precursor powder described in the first step is loaded into the Fe metal tube with one end closed and pickled to obtain a filled metal tube. The pickling treatment is pickling with a mixture of concentrated hydrochloric acid and water, then washing the residual acid solution with water, then rinsing with absolute ethanol, and plac...

Embodiment 3

[0047] 19-core MgB 2 Preparation of superconducting materials:

[0048] The first step: under the protective environment of argon (volume percentage is 99.999%, the balance is air), atomized magnesium powder (purity is 99.5%, average particle diameter is 25 μm), amorphous boron powder (purity is 98%, with an average particle size of 0.53 μm), weighed according to the atomic ratio Mg:B=1.2:2, mixed and ball milled. The total time of ball milling is 3 hours, and the ball mill stops running for 5 minutes every 30 minutes to prevent the reaction between magnesium powder and boron powder caused by overheating of the powder.

[0049] The second step: the precursor powder described in the first step is loaded into the Fe metal tube with one end closed and pickled to obtain a filled metal tube. The pickling treatment is pickling with a mixture of concentrated hydrochloric acid and water, then washing the residual acid solution with water, then rinsing with absolute ethanol, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com