Ga2o3/(Ga1-xFex)2o3 film with room temperature ferromagnetism and high ultraviolet light permeation function and the manufacturing method thereof

A room temperature ferromagnetism and ultraviolet light technology, which is applied in the manufacture/processing of electromagnetic devices, material selection, etc., to achieve the effect of simple and common equipment, which is conducive to popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

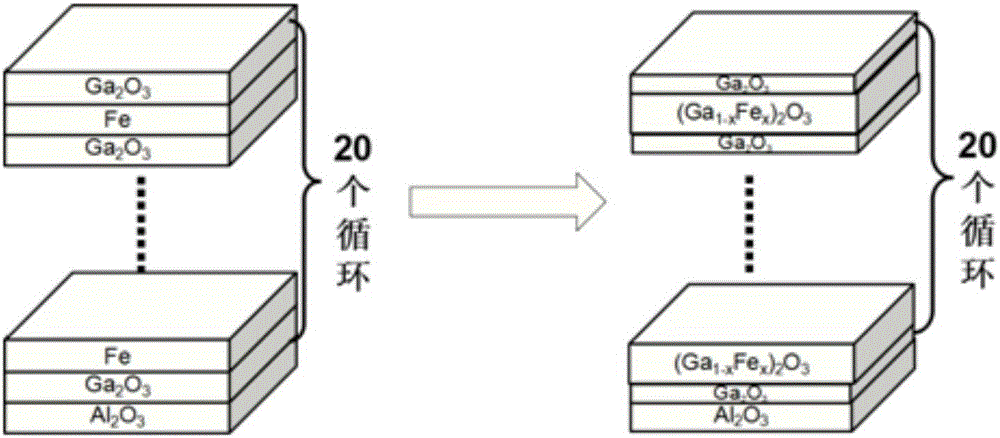

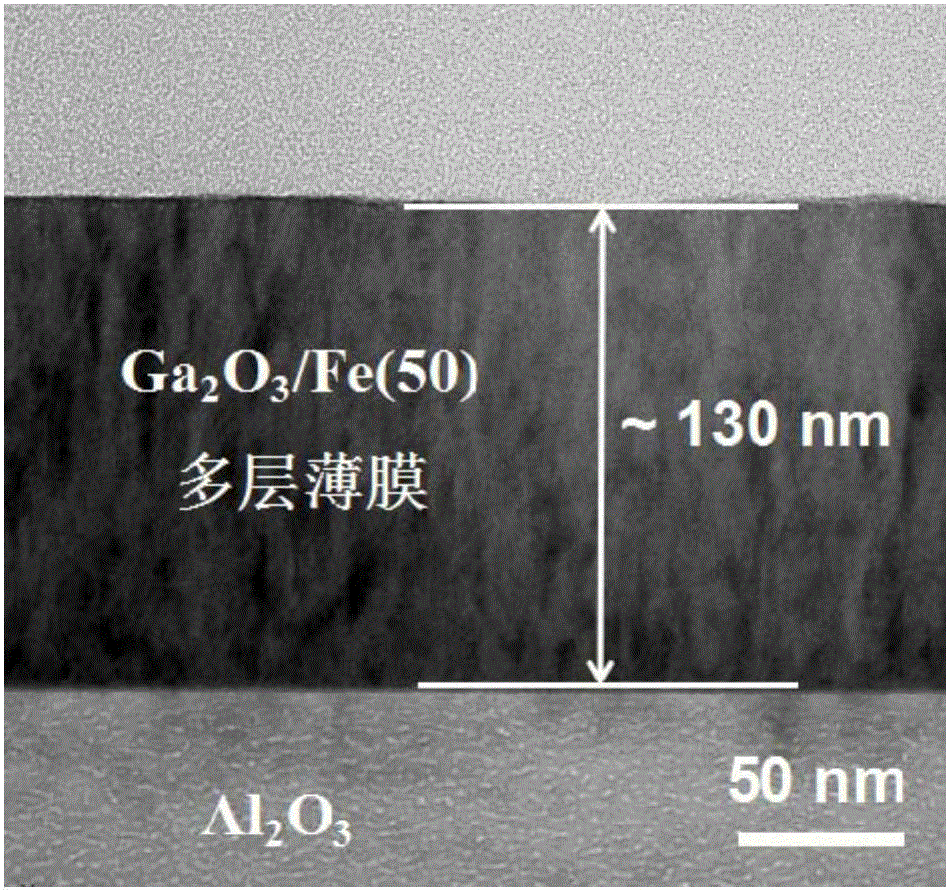

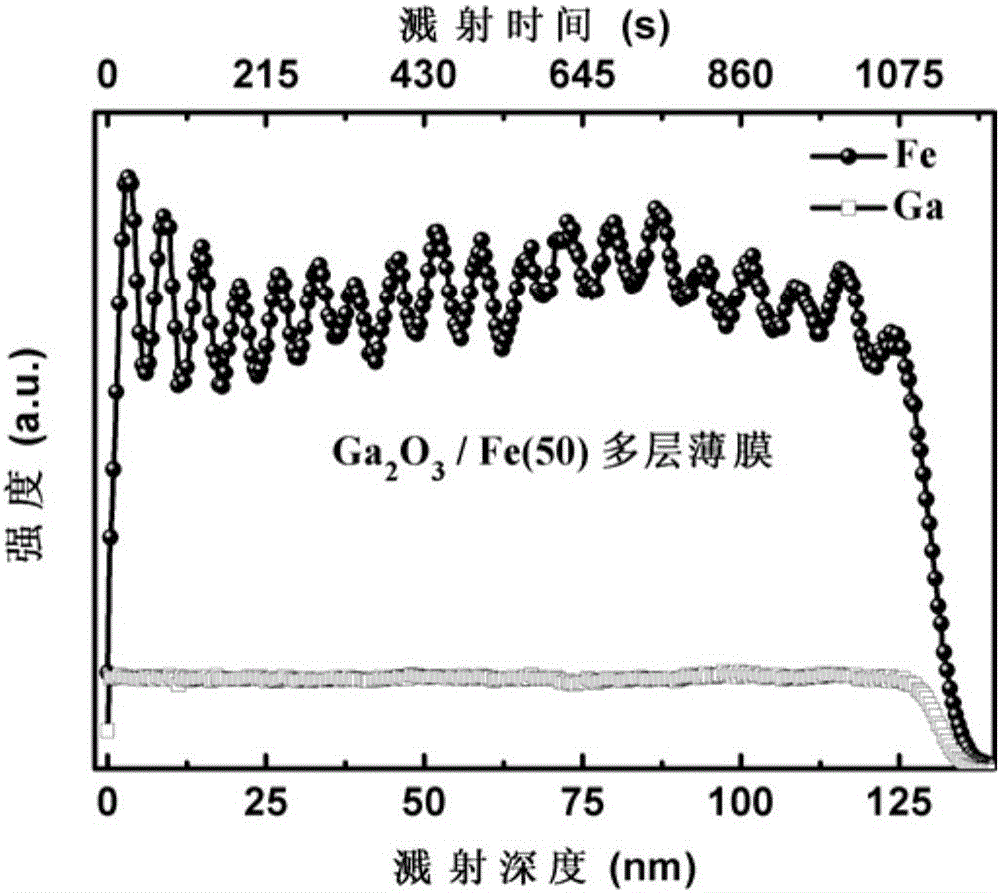

[0020] Example 1 Growth of Ga 2 o 3 / Fe(50) multilayer film

[0021] The specific steps are as follows: (1) Using the c-plane sapphire as the substrate, soak the substrate in acetone, ethanol, and deionized water for 10 minutes, then rinse it with deionized water after taking it out, and finally wash it with dry N 2 Air dry, stand-by; (2) with 99.99% pure Ga 2 o 3 Ceramics and 99.99% pure metal Fe are used as targets, and Ga 2 o 3 and the Fe metal target are placed on the target platform of the laser molecular beam epitaxy system, and the sapphire substrate processed in step (1) is fixed on the sample holder and put into the vacuum chamber; (3) the chamber is evacuated, and the substrate is heated. bottom, first grow Ga on the c-plane of the sapphire substrate 2 o 3 Thin film, then rotate the orbiting target to the metal Fe target, deposit Fe thin film, switch the target by continuously rotating the orbiting target, and continue to alternately and repeatedly deposit Ga ...

Embodiment 2

[0024] Example 2 Growth of Ga 2 o 3 / Fe(20) multilayer film

[0025] Steps (1) and (2) are all the same as in Example 1. The number of laser pulses for depositing the Fe thin film in step (3) is 20 times. The test results are all similar to Example 1.

Embodiment 3

[0026] Example 3 Growth of Ga 2 o 3 / Fe(0) film

[0027] Steps (1) and (2) are all the same as in Example 1. Deposit Ga in step (3) 2 o 3 The number of laser pulses for the thin film was 2000 times. Among them, the working air pressure is 1×10 -6 Pa, substrate temperature 900°C, target base distance 5cm, laser energy 5J / cm 2 , the laser frequency is 1 Hz; after the growth is completed, anneal in situ at 900 ° C for 30 minutes to obtain Ga 2 o 3 / Fe(0) multilayer films.

[0028] Figure 5 Ga 2 o 3 X-ray diffraction patterns (N=0, 10, 20, 30, 40, 50, 100) of Fe(N) multilayer films, it can be seen from the figure that, except for the sample Ga 2 o 3 / Fe(100), only found crystal plane family, indicating that all samples are β-phase Ga preferentially grown along the (201) crystal plane 2 o 3 film. From Figure 5 As can be seen from the enlarged figure of (b), Ga 2 o 3 / Fe(10), Ga 2 o 3 / Fe(20), Ga 2 o 3 / Fe(30), Ga 2 o 3 / Fe(40), Ga 2 o 3 Corresponding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com