Method for adsorption and separation of molybdenum from aqueous phase

A technology of adsorption separation and water phase, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as high toxicity, no high-efficiency recovery path, molybdenum element is in the research stage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

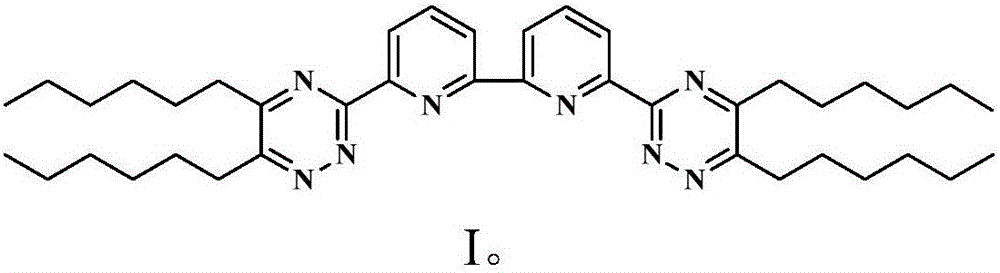

[0036] Dissolve 0.5 g of 6,6'-bis(5,6-dihexyl-1,2,4-triazin-3-yl)-2,2'-bipyridine of formula I in 60.0 ml of dichloromethane , fully dissolved to obtain a golden yellow transparent solution; add 4.5 grams of SiO to this golden yellow solution 2 -P Stir well to make SiO 2 -P is mixed with the compound evenly, and most of the dichloromethane is volatilized by rotary evaporation under reduced pressure until the material reaches a near-dry state, and the organic molecules enter SiO under the action of capillary action and physical adsorption. 2 -P pores, and then vacuum-dry the nearly dry material at 55°C for 24 hours to obtain C6-BTBP / SiO 2 -P composite material, namely adsorbent.

Embodiment 2

[0038] Dissolve 0.5 g of 6,6'-bis(5,6-dihexyl-1,2,4-triazin-3-yl)-2,2'-bipyridine of formula I in 50.0 ml of dichloromethane , fully dissolved to obtain a golden yellow transparent solution; add 4.0 grams of SiO to this golden yellow solution 2 -P Stir well to make SiO 2 -P is mixed with the compound evenly, and most of the dichloromethane is volatilized by rotary evaporation under reduced pressure until the material reaches a near-dry state, and the organic molecules enter SiO under the action of capillary action and physical adsorption. 2 -P pores, and then vacuum-dry the nearly dry material at 55°C for 24 hours to obtain C6-BTBP / SiO 2 -P composite material, namely adsorbent.

Embodiment 3

[0040] Dissolve 0.5 g of 6,6'-bis(5,6-dihexyl-1,2,4-triazin-3-yl)-2,2'-bipyridine of formula I in 75.0 ml of dichloromethane , fully dissolved to obtain a golden yellow transparent solution; add 5.0 grams of SiO to this golden yellow solution 2 -P Stir well to make SiO 2 -P is mixed with the compound evenly, and most of the dichloromethane is volatilized by rotary evaporation under reduced pressure until the material reaches a near-dry state, and the organic molecules enter SiO under the action of capillary action and physical adsorption. 2 -P pores, and then vacuum-dry the nearly dry material at 55°C for 24 hours to obtain C6-BTBP / SiO 2 -P composite material, namely adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com