Copper-sulphur separation and ore dressing method for high-sulphur copper ores

A technology of copper-sulfur separation and beneficiation method is applied in the field of copper and sulfur separation of high-sulfur copper ores, and the beneficiation of high-sulfur copper ores, and can solve the problems of unsatisfactory separation effect, adverse environmental impact, difficult production control and the like, Achieve significant effect of energy saving and consumption reduction, improve grade and recovery rate, and reduce the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

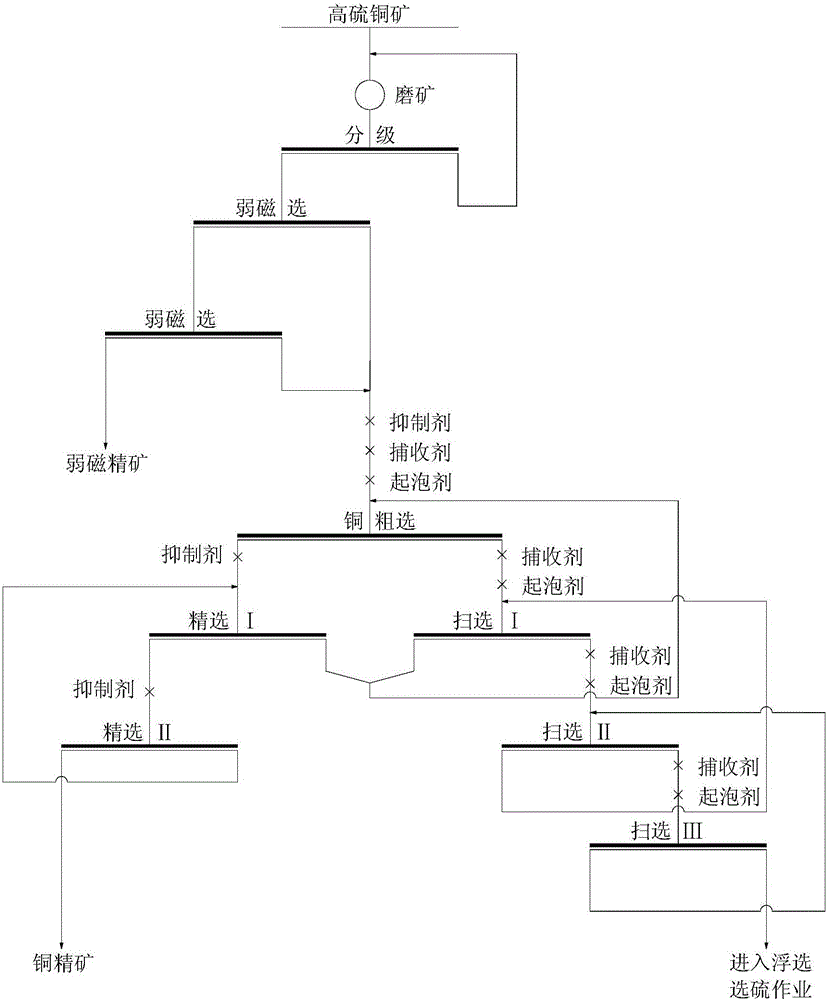

[0024] In order to further describe the present invention, a copper-sulfur separation and beneficiation method for high-sulfur copper ore of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0025] The raw ore adopted in the embodiment is the high-sulfur copper ore of a certain non-ferrous metal mine. The raw ore contains 0.94% copper and 12.53% sulfur. The sulfur minerals are pyrrhotite and pyrite. Pyrite accounts for 17.57%, and pyrite accounts for 6.90%. It is a high-sulfur, difficult-to-select copper and pyrite composite ore.

[0026] Depend on figure 1 The principle process flow chart of the copper-sulfur separation ore dressing method of a kind of high-sulfur copper ore of the present invention shown, the copper-sulfur separation ore dressing method of a kind of high-sulfur copper ore of the present invention comprises following technology, step:

[0027] (1) The high-sulfur copper ore is ground-classified, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com