A kind of synthetic method of silicalite-1 molecular sieve

A synthesis method and technology of reaction mixture are applied in the direction of crystalline aluminosilicate zeolite to achieve the effect of complete crystal form and few framework defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

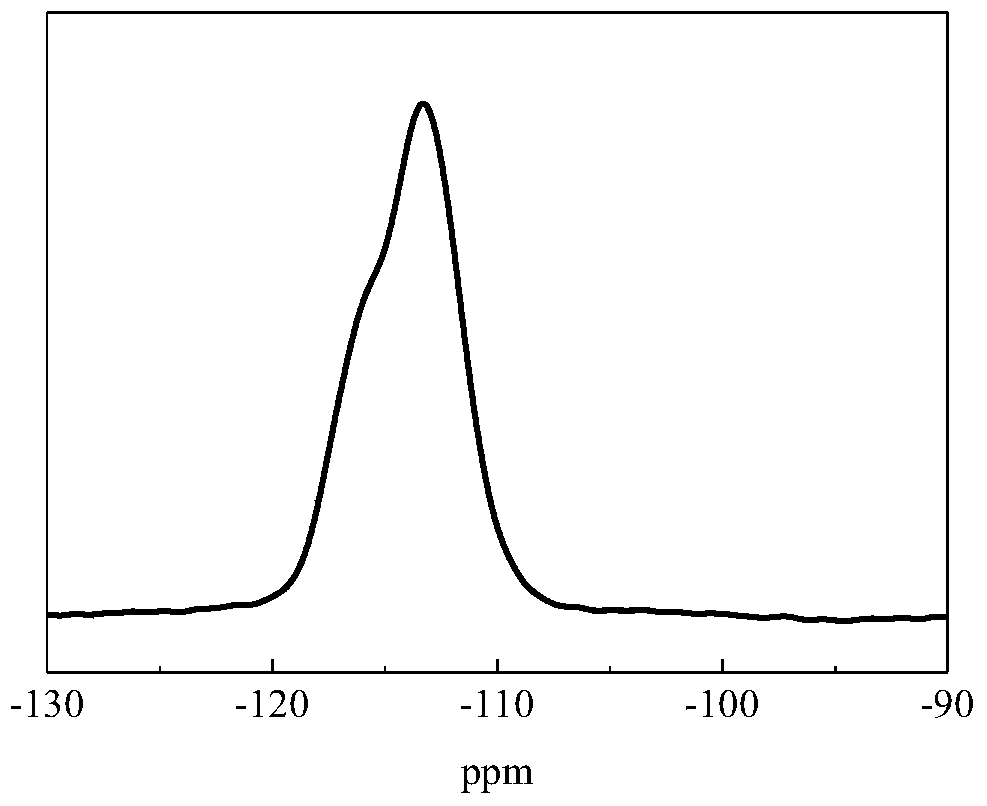

[0026]The invention provides a kind of synthetic method of Silicalite-1 molecular sieve, comprises the following steps:

[0027] (1) Mix the silicon source, structure directing agent, water and optional alkali source evenly to obtain a molar ratio of SiO 2 :R:OH - :H 2 The reaction mixture of O=1: (0.05-0.39): (0.05-2): (2-100), wherein, R represents the molar number of the structure directing agent in the reaction mixture; the structure directing agent is selected from tetraethyl At least one of ammonium hydroxide, tetraethylammonium bromide, tetraethylammonium chloride, tetraethylammonium fluoride, tetraethylammonium iodide and triethylamine;

[0028] (2) By mineralizer: OH - =(1-5): 1 molar ratio, adding a halogen-containing acidic mineralizer or an acidic halogen-containing mineralizer after hydrolysis to the reaction mixture obtained in step (1), after stirring evenly, the mixture Transfer to a pressure-resistant airtight container, and crystallize at a temperature of...

Embodiment 1

[0047] At a stirring speed of 400r / min, according to SiO 2 :R:OH - :H 2 O=1:0.2:0.2:20 molar ratio, mix ethyl orthosilicate, tetraethylammonium hydroxide and deionized water evenly, and hydrolyze at 50°C for 18 hours to obtain clear orthosilicate Hydrolyzed solution of ethyl ester. Under the stirring condition of 600r / min, according to mineralizer: OH - =1:1 molar ratio, add hydrofluoric acid to the mixed solution, stir evenly, transfer the resulting mixture into a closed pressure-resistant container.

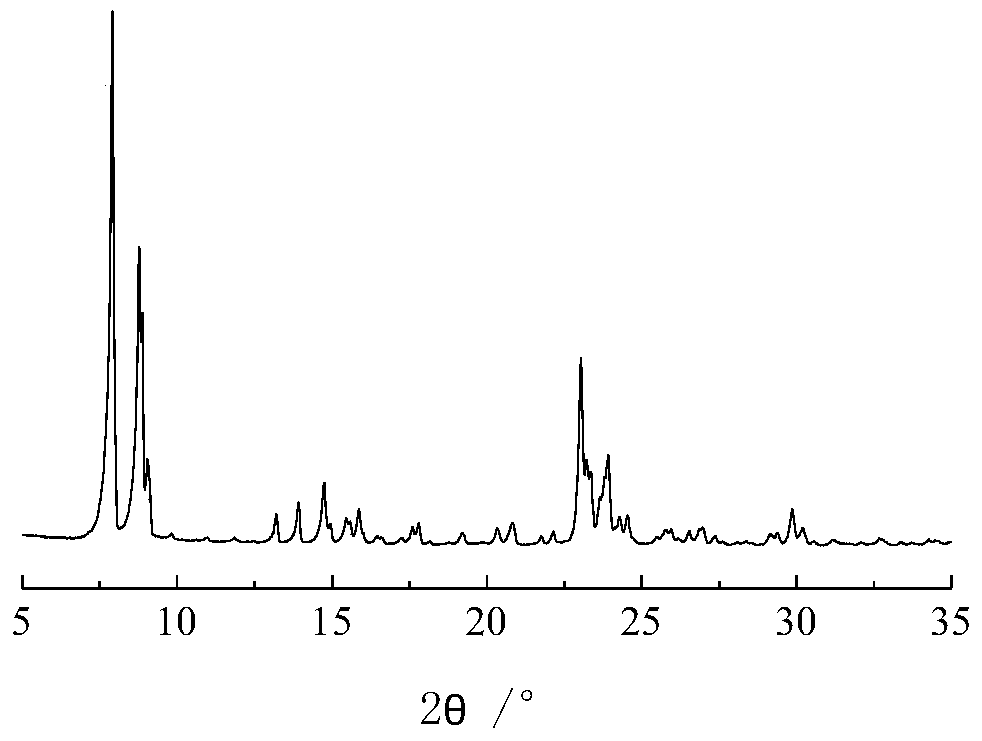

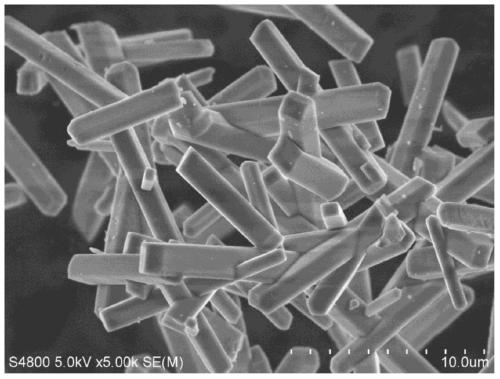

[0048] Under the stirring condition of 400r / min, the temperature of the crystallization system was raised to 150°C, and the temperature was kept at autogenous pressure for 6 days to obtain a mixture of crystallized products; the mixture was filtered and washed with water for several times; at a temperature of 110°C Dry for 6 hours, and grind the dried mixture evenly to obtain the raw powder of unroasted Silicalite-1 molecular sieve; finally, roast the raw powder of Silicali...

Embodiment 2

[0050] At a stirring speed of 400r / min, according to SiO 2 :R:OH - :H 2 O=1:0.3:1:30 molar ratio, mix silica gel, tetraethylammonium hydroxide, lithium hydroxide and deionized water uniformly, and hydrolyze at 30°C for 24 hours to obtain a hydrolysis solution of silica gel. Under the stirring condition of 400r / min, according to mineralizer: OH - =1.5:1 molar ratio, add hydrofluoric acid to the mixed solution, stir evenly, transfer the resulting mixture into a closed pressure-resistant container.

[0051] Under the condition of stirring at 300r / min, the temperature of the crystallization system was raised to 135°C, and the temperature was kept at autogenous pressure for 12 days to obtain a mixture of crystallized products; the mixture was filtered and washed with water several times; at a temperature of 130°C Dry for 4 hours, and grind the dried mixture evenly to obtain the raw powder of unroasted Silicalite-1 molecular sieve; finally, roast the raw powder of Silicalite-1 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com