A kind of sulfonated naphthalene ether grafted fluorine-containing polyether proton exchange membrane and preparation method thereof

A proton exchange membrane and fluorine-containing polyether technology, which is applied in the field of sulfonated naphthalene ether grafted fluorine-containing polyether proton exchange membrane and its preparation, can solve the problem of difficult control of polymer synthesis conditions, complex synthesis routes, and difficult scale problems such as chemical production, to achieve the effects of controllable sulfonation degree, simple synthesis process and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

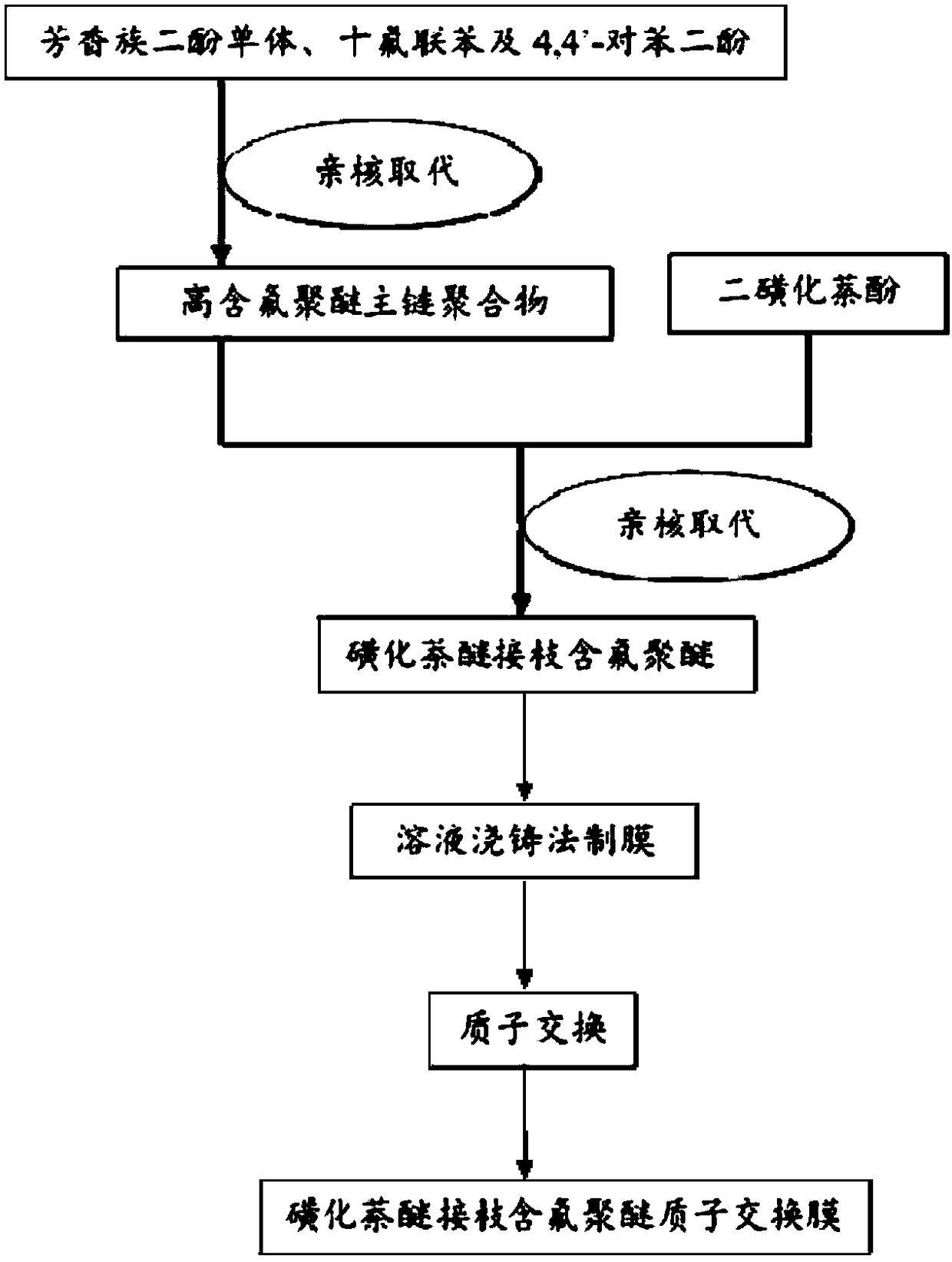

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of sulfonated naphthalene ether grafted fluorine-containing polyether proton exchange membrane sSPFAE(SDP)-SNA-0.55 (A1).

[0048] Preparation of fluorine-containing hydrophobic backbone polymer: 0.463 g (2.5 mmol) 4,4'-dihydroxybiphenyl, 0.625 g (2.5 mmol) 4,4'-dihydroxyphenyl sulfone and 1.687 g (5.05 mmol) Decafluorobiphenyl was added to a three-necked flask, 11 mL of DMAc, 0.828 g (6 mmol) of anhydrous potassium carbonate, and 10 mL of cyclohexane were added. The temperature was raised to 90° C. for 10 hours and then lowered to room temperature. The product was poured into deionized water to precipitate a fibrous product, which was thoroughly washed with water and vacuum-dried at 80° C. for 24 hours to obtain a white product.

[0049] Preparation of sSPFAE(SDP)-SNA-0.55: Add 3.726 g (3.636 mmol) of the above-mentioned fully dried polymer and 18 mL of DMAc into a three-necked flask. After the solid is completely dissolved, add pre-dissolved in...

Embodiment 2

[0051] Example 2: Preparation of sulfonated naphthalene ether grafted fluorine-containing polyether proton exchange membrane sSPFAE(SDP)-SNA-0.60 (A2)

[0052] Similar to the preparation method of A(1) in Example 1, the difference is that the amount of 1-naphthol-3,6-disulfonic acid sodium and potassium carbonate is different, and 1-naphthol-3,6-disulfonic acid The amount of sodium used was 0.784 g (2.25 mmol), and the amount of potassium carbonate used was 0.373 g (2.7 mmol) to obtain proton-type sulfonated polymer membrane A2.

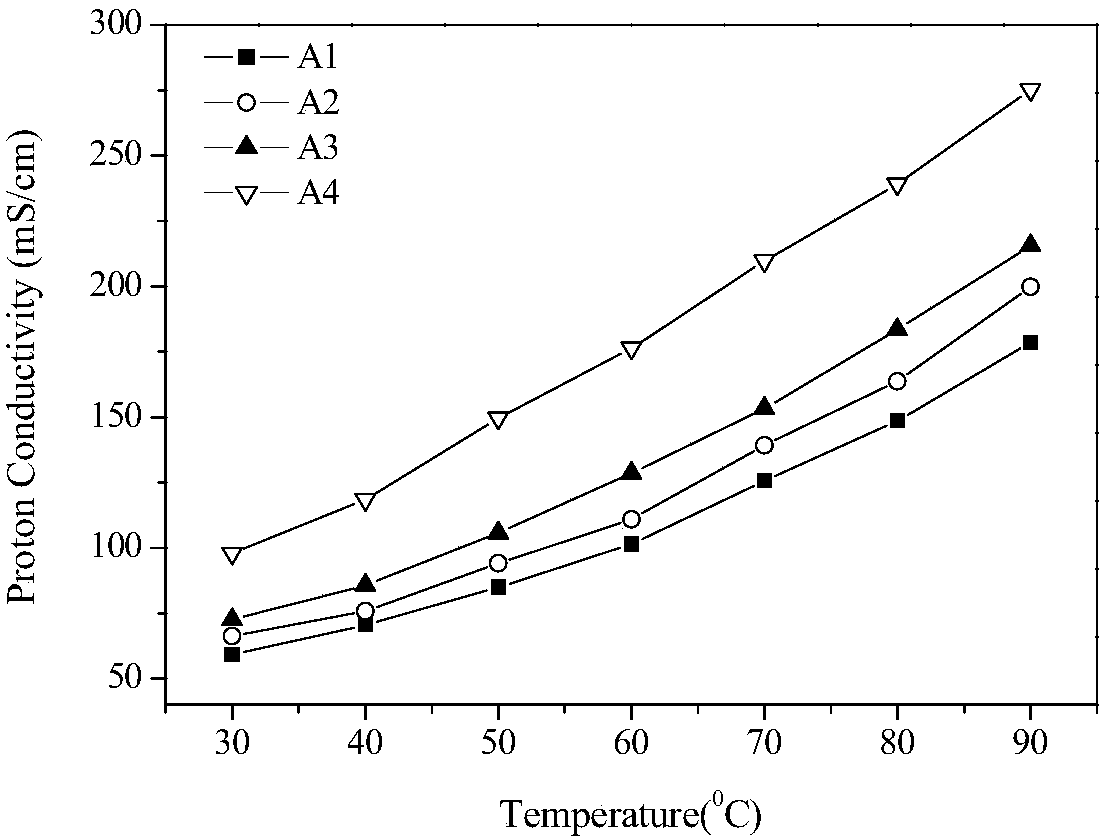

[0053] Its performance data is shown in Table 1, and the conductivity in water at different temperatures is shown in figure 2 .

Embodiment 3

[0054] Example 3: Preparation of sulfonated naphthalene ether grafted fluorine-containing polyether proton exchange membrane sSPFAE(SDP)-SNA-0.65 (A3)

[0055] Similar to the preparation method of A(1) in Example 1, the difference is that the amount of 1-naphthol-3,6-disulfonic acid sodium and potassium carbonate is different, and 1-naphthol-3,6-disulfonic acid The amount of sodium used was 0.871 g (2.5 mmol), and the amount of potassium carbonate used was 0.414 g (3.0 mmol) to obtain proton-type sulfonated polymer membrane A3.

[0056] Its performance data is shown in Table 1, and the conductivity in water at different temperatures is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com