Toughening material for SLS and preparation method of toughening material

A technology of toughening and raw materials, which is applied in the field of SLS toughening materials, can solve the problems of poor toughness, difficulty in wide application, strong skin irritation, etc., achieves improved impact strength and elongation at break, simple preparation process, and good processing toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

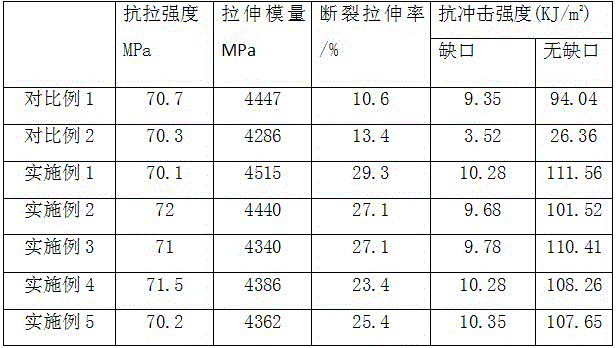

Examples

Embodiment 1

[0033] A preparation method for a toughened material for SLS, comprising the following steps:

[0034] Step 1, take each material for subsequent use, wherein each component mass percent is respectively: nylon 6 powder 98%, fumed silicon dioxide 0.5%, nickel titanium yellow 1%, antioxidant 9228 0.5%, get 15% Nylon resin is mixed with fumed silica, antioxidant 9228 and nickel-titanium yellow and stirred with a high-speed stirrer to ensure that the fumed silica is completely crushed and fully mixed to obtain a powder-inducing material; among them, the particle size of nylon 6 powder is 20 μm, The particle size of the nickel titanium yellow powder is 2 μm.

[0035] Step 2, using a V-shaped mixer to fully stir and mix the powder-inducing material and the remaining nylon resin for 30 minutes to obtain a toughened material.

Embodiment 2

[0037] A preparation method for a toughened material for SLS, comprising the following steps:

[0038] Step 1, take each material for subsequent use, wherein the mass percentages of each component are respectively: nylon 1212 powder 95%, fumed silicon dioxide 0.1%, nickel titanium orange 3%, antioxidant 9228 0.9%, get 18% Nylon resin is mixed with fumed silica, antioxidant 3026 and nickel-titanium orange and stirred with a high-speed stirrer to ensure that the fumed silica is completely broken and mixed thoroughly to obtain powder-inducing materials; among them, the particle size of nylon 1212 powder is 35 μm, The particle size of the nickel titanium yellow powder is 50 μm.

[0039] Step 2, using a V-shaped mixer to fully stir and mix the powder-inducing material and the remaining nylon resin for 45 minutes to obtain a toughened material.

Embodiment 3

[0041] A preparation method for a toughened material for SLS, comprising the following steps:

[0042] Step 1. Weigh each material for later use, wherein the mass percentages of each component are: 95% of nylon 12 powder, 1% of fumed silica, 2.7% of nickel titanium yellow, antioxidant 9228 and antioxidant 3026 according to the mass ratio of 1 : 1 mixed antioxidant 0.3%, glass fiber 1%, get 18% nylon resin and fumed silicon dioxide, antioxidant 9228, antioxidant 3026 and nickel-titanium yellow to mix and utilize high-speed stirrer to stir, ensure The fumed silica is completely crushed and fully mixed to obtain powder-inducing materials; wherein, the particle size of the nylon 12 powder is 80 μm, and the particle size of the nickel titanium yellow powder is 80 μm.

[0043] Step 2, using a V-shaped mixer to fully stir and mix the powder-inducing material and the remaining nylon resin for 50 minutes to obtain a toughened material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com