A kind of modified titanium dioxide coated with polyacrylic acid

A technology of polyacrylic acid and titanium dioxide, which is applied in the treatment of dyed polymer organic compounds, inorganic pigments, fibrous fillers, etc., can solve the problems of high equipment cost and complex modification process of chemical fiber titanium dioxide, and achieve good dispersibility, Improves gloss and hiding power, enhances bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

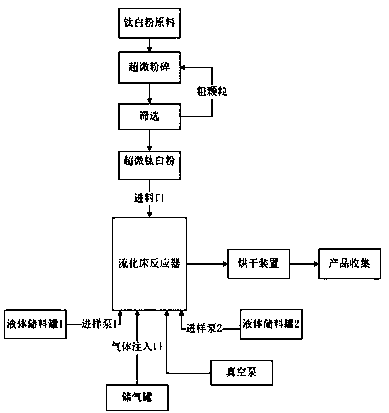

[0037] In the embodiment of the present invention, the present invention proposes a preparation method of modified titanium dioxide coated with polyacrylic acid, the method specifically includes the following steps:

[0038] a. Dissolve the polyacrylic acid in the prescribed amount in an organic solvent to prepare feed liquid 1; wherein, the mass ratio of the polyacrylic acid to the organic solvent is 1:1-1.1, and the organic solvent can be in ethanol or propylene glycol at least one of .

[0039] b. Dissolve the prescribed amount of sodium silicate in an organic solvent to prepare feed liquid 2; wherein, the mass ratio of the sodium silicate to the organic solvent is 1:4 to 4.5, and the organic solvent can be ethanol or at least one of propylene glycol.

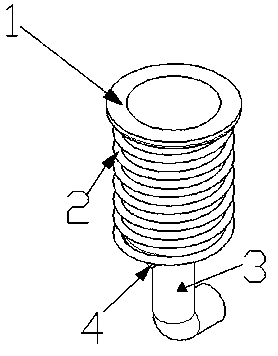

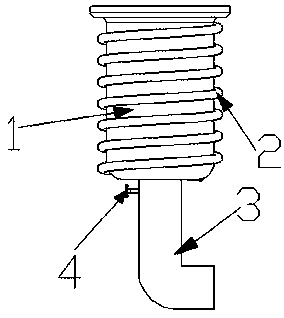

[0040] c. Take the prescribed amount of untreated titanium dioxide raw material and enter it into the screening device after being pulverized by the superfine pulverization device. The feeding port of the fluidized bed is ...

Embodiment 1

[0049] A preparation method of modified titanium dioxide coated with polyacrylic acid, comprising the following steps:

[0050] a. Mix 150g of polyacrylic acid and 150g of ethanol to prepare feed liquid 1;

[0051] b. Mix 5g of sodium silicate and 20g of propylene glycol to prepare feed liquid 2;

[0052] c. Take 10kg of untreated titanium dioxide raw material and pass it through the superfine pulverization device, then enter the screening device, return the particles with a particle size larger than 300nm to the superfine pulverization device for re-crushing, and pass the particles with a particle size smaller than 300nm through the fluidized bed reactor The feeding port is placed in the cavity of the fluidized bed reactor;

[0053] d. Turn on the vacuum pump, evacuate the fluidized bed reactor, feed nitrogen gas from the gas injection port, control the flow rate through the pressure gauge, adjust the gas flow rate to 4L / min, and keep the titanium dioxide particles in a susp...

Embodiment 2

[0057] A preparation method of modified titanium dioxide coated with polyacrylic acid, comprising the following steps:

[0058] a. Mix 180g of polyacrylic acid and 180g of ethanol to prepare feed liquid 1;

[0059] b. Mix 4g of sodium silicate and 18g of ethanol to prepare feed liquid 2;

[0060] c. Take 10kg of untreated titanium dioxide raw material and pass it through the superfine pulverization device, then enter the screening device, return the particles with a particle size larger than 300nm to the superfine pulverization device for re-crushing, and pass the particles with a particle size smaller than 300nm through the fluidized bed reactor The feeding port is placed in the cavity of the fluidized bed reactor;

[0061] d. Turn on the vacuum pump, evacuate the fluidized bed reactor, feed nitrogen gas from the gas injection port, control the flow rate through the pressure gauge, adjust the gas flow rate to 4.5L / min, and keep the titanium dioxide particles in a suspended s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com