Composite material MoO3/Polyaniline/Ti3C2Tx and preparation method thereof

A composite material and powder technology, applied in the field of composite material preparation, can solve the problems that graphene cannot meet the performance requirements, limited application, poor electrical conductivity, etc., and achieves improved electrochemical performance, great adjustability, and improved electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steps of this embodiment include:

[0023] (1) The Ti prepared by hot pressing sintering 3 AlC 2 The powder is completely immersed in the HF solution with a volume fraction of 40%, stirred at room temperature for 24 hours, washed with water to PH=6, washed with alcohol, centrifuged to obtain the powder and dried in a vacuum oven;

[0024] (2) Weigh 0.3g of ammonium molybdate tetrahydrate and 1.2g of tartaric acid to be completely dissolved in water to obtain an aqueous solution, stir evenly at 25°C, and adjust the pH to 0.5 with 6mol / L HCl;

[0025] (3) Ti obtained in step (1) 3 C 2 T x Weigh 0.15g of the powder, add it into the solution obtained in step (2) at a constant speed, and stir at 25°C for 9 hours;

[0026] (4) centrifuging the suspension obtained in step (3), washing with water, washing with alcohol, and drying in a vacuum oven;

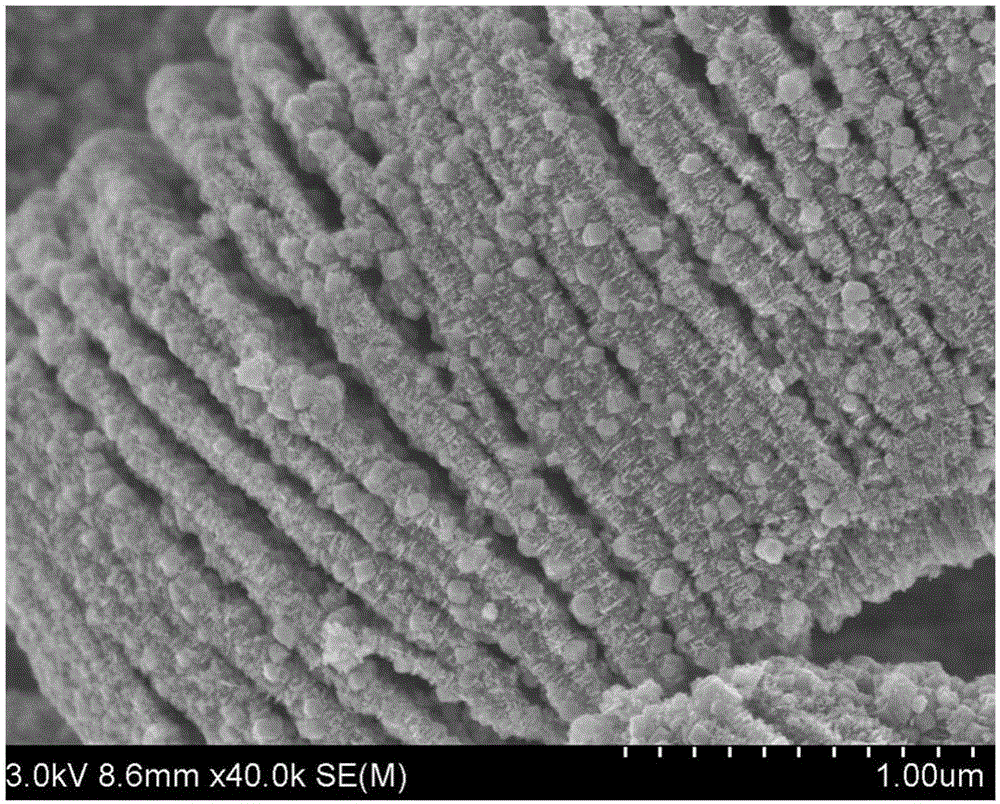

[0027] (5) Sinter the powder obtained in step (4) at 550°C under an argon atmosphere and keep it warm for 2 hours to obt...

Embodiment 2

[0036] The steps of this embodiment include:

[0037] (1) The Ti prepared by hot pressing sintering 3 AlC 2 The powder is completely immersed in the HF solution with a volume fraction of 40%, stirred at room temperature for 24 hours, washed with water to PH=6, washed with alcohol, centrifuged to obtain the powder and dried in a vacuum oven;

[0038] (2) Weigh 0.1g of ammonium molybdate tetrahydrate and 0.2g of tartaric acid to be completely dissolved in water to obtain an aqueous solution, stir evenly at 25°C, and adjust the pH to 0.5 with 6mol / L HCl;

[0039] (3) Ti obtained in step (1) 3 C 2 T x Weigh 0.15g of the powder, add it into the solution obtained in step (2) at a constant speed, and stir at 25°C for 6 hours;

[0040] (4) centrifuging the suspension obtained in step (3), washing with water, washing with alcohol, and drying in a vacuum oven;

[0041] (5) Sinter the powder obtained in step (4) at 600°C under an argon atmosphere and keep it warm for 1h to obtain M...

Embodiment 3

[0047] The steps of this embodiment include:

[0048] (1) The Ti prepared by hot pressing sintering 3 AlC 2 The powder is completely immersed in the HF solution with a volume fraction of 40%, stirred at room temperature for 24 hours, washed with water to PH=6, washed with alcohol, centrifuged to obtain the powder and dried in a vacuum oven;

[0049] (2) Weighing 0.5g of ammonium molybdate tetrahydrate and 1.5g of tartaric acid were completely dissolved in water to obtain an aqueous solution, stirred evenly at 25°C, and adjusted to PH=0.5 with 6mol / L HCl;

[0050] (3) Ti obtained in step (1) 3 C 2 T x Weigh 0.15g of the powder, add it into the solution obtained in step (2) at a constant speed, and stir at 25°C for 9 hours;

[0051] (4) centrifuging the suspension obtained in step (3), washing with water, washing with alcohol, and drying in a vacuum oven;

[0052] (5) Sinter the powder obtained in step (4) at 550°C under an argon atmosphere and keep it warm for 2 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com