Infrared LED (Light-Emitting Diode)

A light-emitting diode and infrared light-emitting technology, applied in the field of optoelectronics, can solve the problems of high resistivity of materials, poor antistatic resistance of current diffusion components, etc., and achieve the effects of improving luminous efficiency, improving red burst phenomenon, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

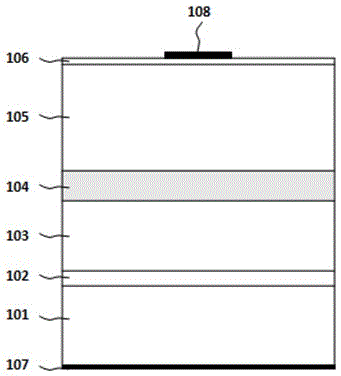

[0041] Such as figure 1 As shown, an infrared light-emitting diode chip with a low-bandgap covering layer includes, from top to bottom, a P-type ohmic electrode 108, a contact layer 106, a P-type covering layer 105, a quantum well active layer 104, and an N-type covering layer 103. , buffer layer 102, GaAs substrate 101, N-type ohmic electrode 107. In this embodiment, the multi-quantum well active layer is grown by metal-organic vapor phase epitaxy (OMVPE), with InGaAs as the well layer and AlGaAsP as the barrier layer. The luminescence peak wavelength is above 900nm, and the number of quantum wells is between Between 3 pairs and 25 pairs.

[0042] Specifically, the GaAs substrate 101 is a single crystal N-type GaAs substrate doped with Si, with a concentration of 8E17-3E18 atoms / cm, preferably 1.2E18 atoms / cm; the buffer layer 102 is made of GaAs, with a concentration of Between 8E17~5E18 atoms / cm, the preferred concentration is 1.5E18 atoms / cm; the N-type cladding layer is...

Embodiment 2

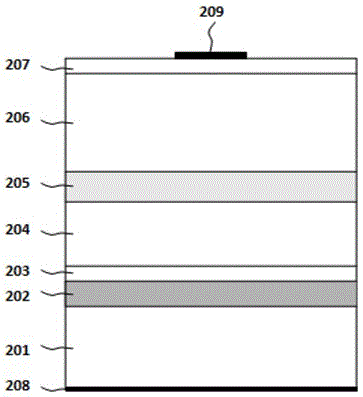

[0046] Such as figure 2 As shown, an infrared light-emitting diode chip with a low-bandgap covering layer includes, from top to bottom, an N-type ohmic electrode 209, an N-type contact layer 207, an N-type covering layer 206, an active layer 205, and a P-type covering layer 204. , P-type contact layer 203 , metal bonding layer 202 , Si substrate 201 and P-type ohmic electrode 208 . In this embodiment, a Si substrate is used, and a metal bonding layer is used to reflect downward light from the active layer, so as to effectively improve light extraction, thereby improving luminous efficiency.

[0047] Specifically, the N-type cladding layer 206 and the P-type cladding layer 204 are made of indium gallium arsenide In x Ga 1-x As, wherein the indium component X is between 0%~5%, preferably X is 2%, the concentration is 5E17~2E18 atoms / cm, and the preferred concentration is 7E17 atoms / cm. The active layer 205 is a multi-quantum well layer, including a well layer and a barrier l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com