Metal gradient doped lithium battery positive electrode material

A cathode material, gradient doping technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of loss of high energy density, material capacitance decline, reduced industrial availability, etc., to achieve good electrochemical characteristics and thermal stability. The effect of improving the overall operation efficiency and improving the industrial utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

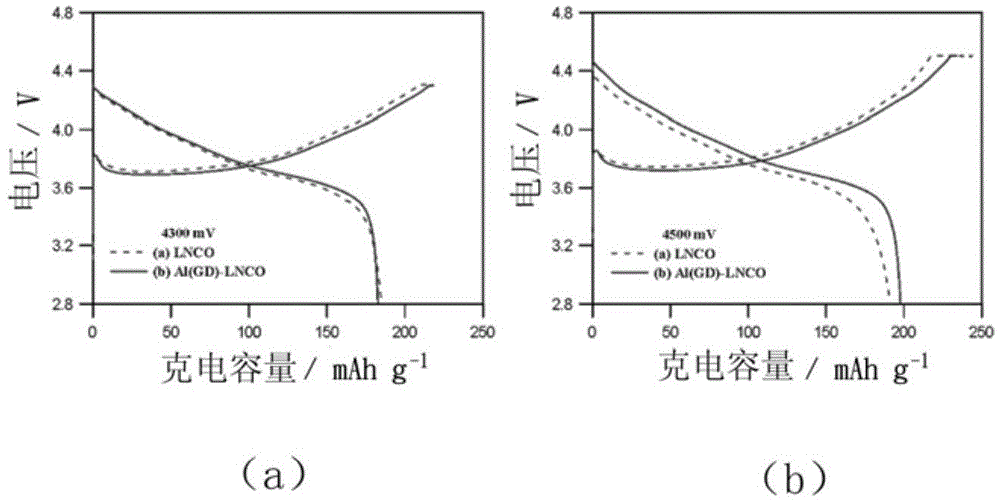

[0042] The test result of embodiment 1 and comparative example 1 is described as follows, test result is as follows Figure 2 to Figure 6 shown.

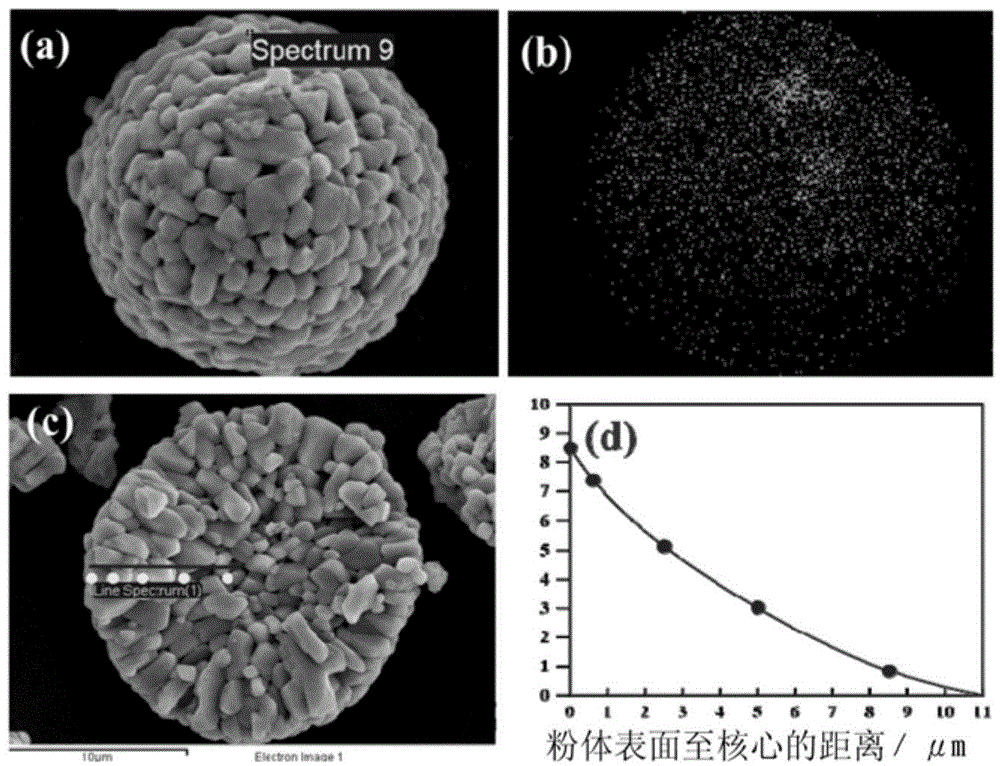

[0043] Regarding the analysis of physical characteristics, the positive electrode material of the embodiment Al(GD)-LNCO was quantitatively analyzed for the whole, surface and section by using inductively coupled plasma atomic emission spectrometry (ICP / OES) and energy dispersive spectrometer (EDS). The molar ratio of the aluminum element doped into the lithium nickel cobalt oxide as a whole was determined by ICP / OES to be 2.55%. figure 2 (a) is the surface morphology of Al(GD)-LNCO cathode material, and figure 2 (b) is the aluminum element distribution map on the surface of the Al(GD)-LNCO cathode material, showing that there is indeed a high dose of aluminum element on the surface of the Al(GD)-LNCO cathode material. also, figure 2 (c) is the cross-sectional shape of the Al(GD)-LNCO cathode material, which can show that ther...

Embodiment 2

[0055] The test result of embodiment 2 and comparative example 2 is described as follows, test result is as follows Figure 7 to Figure 11 shown.

[0056] Regarding the analysis of physical characteristics, the positive electrode material of the embodiment Mg(GD)-LNCMO was quantitatively analyzed on the whole, surface and section by using inductively coupled plasma atomic emission spectrometry (ICP / OES) and energy dispersive spectrometer (EDS). The molar ratio of magnesium doped into the lithium nickel cobalt manganese oxide as a whole was determined by ICP / OES to be 1.7%. Figure 7 (a) is the surface morphology of Mg(GD)-LNCMO cathode material, while Figure 7 (b) is the magnesium element distribution map on the surface of the Mg(GD)-LNCMO cathode material, showing that there is indeed a high dose of magnesium on the surface of the Mg(GD)-LNCMO cathode material. also, Figure 7 (c) is the cross-sectional shape of the Mg(GD)-LNCMO cathode material, which shows that there is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com