Method for preparing three-dimensional graphene-phosphotungstate

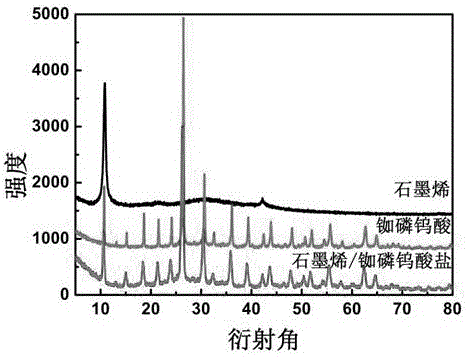

A technology of rubidium phosphotungstate and graphene, which is applied in the field of preparation of lithium-ion battery cathode materials, can solve the problems of poor conductivity of rubidium phosphotungstate, achieve uniform shape, excellent structural stability, and improve discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

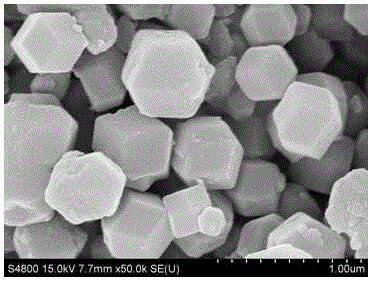

[0024] 1) Preparation of rubidium phosphotungstate:

[0025] In a 250mL three-neck flask, first add 100mL concentration of 15×10 -4 mol / L aqueous solution of phosphotungstic acid, then slowly add 100mL concentration of 5×10 -2 mol / L aqueous solution of rubidium chloride was heated to 100°C and stirred for 1 hour to form a rubidium phosphotungstic acid emulsion. After the reaction was completed, it was cooled to room temperature and separated by suction filtration to obtain rubidium phosphotungstate.

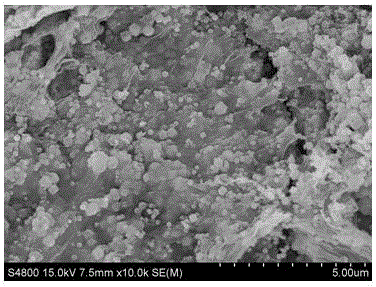

[0026] 2) Preparation of graphene-coated rubidium phosphotungstate:

[0027] Take 0.25g of rubidium phosphotungstate prepared in step 1) and put it into a polytetrafluoroethylene bottle, then add 10mL of graphene oxide aqueous solution with a concentration of 10mg / mL prepared in advance, and stir the mixed solution for one hour at room temperature, Make it fully react, then put the polytetrafluoroethylene bottle into the hydrothermal reaction kettle, and finally put the hydroth...

Embodiment 2

[0029] 1) Preparation of rubidium phosphotungstate:

[0030] Into a 250mL three-neck flask, first add 100mL concentration of 6×10 -4 mol / L aqueous solution of phosphotungstic acid, then slowly add 100mL concentration of 3×10 -2 mol / L aqueous solution of rubidium chloride was heated to 100°C and stirred for 1 hour to form a rubidium phosphotungstic acid emulsion. After the reaction was completed, it was cooled to room temperature and separated by suction to obtain rubidium phosphotungstate.

[0031] 2) Preparation of polyaniline-coated rubidium phosphotungstate:

[0032] Take 0.25g of rubidium phosphotungstate prepared in step 1) and put it into a polytetrafluoroethylene bottle, then add 10mL of graphene oxide aqueous solution with a concentration of 10mg / mL prepared in advance, and stir the mixed solution for one hour at room temperature, Make it fully react, then put the polytetrafluoroethylene bottle into the hydrothermal reaction kettle, and finally put the hydrothermal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com