Biodegradable calcium sulfate/gelatin composite micro needle array patch and preparation method thereof

A microneedle array and calcium sulfate technology, which is applied in the direction of microneedles, needles, and medical devices, can solve the problems of unfavorable skin release of drugs and affecting drug delivery efficiency, and achieve simple preparation steps, convenient operation, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

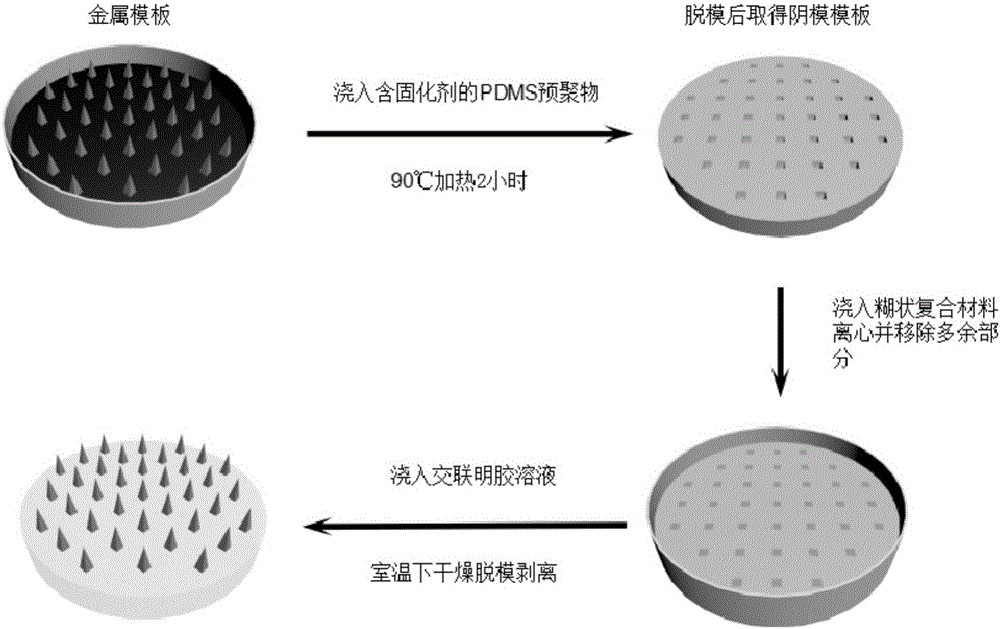

[0032] figure 1 Schematic diagram of the preparation process for the biodegradable calcium sulfate / gelatin composite microneedle array patch. The specific preparation steps are as follows:

[0033] (1) After mixing the liquid polydimethylsiloxane prepolymer and the curing agent at a mass ratio of 10:1, pour it on the microneedle silicon substrate, first vacuumize to remove air bubbles, and then return to normal atmospheric pressure, in Heating at 90°C for 2 hours, demoulding to obtain a microneedle template;

[0034] (2) Dissolve 3.397g of calcium lactate and 1.919g of potassium sulfate in 20mL of 15% aqueous gelatin solution, heat and stir in a water bath at 38°C, and wait for the water to evaporate to about 8mL to obtain a paste mixture;

[0035] (3) After adding 100 μL of 2.5% glutaraldehyde to the paste mixture, stir it evenly and pour it into the microneedle template prepared in step (1), centrifuge at 6000 rpm for 10 minutes, and wait until the paste mixture is filled ...

Embodiment 2

[0040] (1) The preparation of the microneedle template is the same as in Example 1;

[0041](2) Dissolve 6.588g of calcium gluconate and 2.559g of potassium sulfate in 10mL of 12.5% aqueous gelatin solution, heat in a water bath at 38°C and stir thoroughly until the water evaporates to about 10mL to obtain a paste mixture ;

[0042] (3) After adding 150 μL of 1.25% glutaraldehyde and 2 mg of insulin to the paste mixture, stir it evenly and pour it onto the microneedle template prepared in step (1), centrifuge at 6000 rpm for 15 minutes, and wait for the paste to form After the mixture fills the mold cavity, remove excess pasty mixture from the formwork surface;

[0043] (4) At room temperature, add dropwise a mixed solution consisting of 4 mL of 10% gelatin and 0.5 mL of 1.5% genipin above the mold cavity;

[0044] (5) After the mixed solution completely covers the surface of the mold cavity, place the microneedle template in a ventilated place to dry naturally. After demo...

Embodiment 3

[0046] (1) The preparation of the microneedle template is the same as in Example 1;

[0047] (2) Dissolve 2.449g of calcium chloride and 3.132g of sodium sulfate in 10mL of 20% aqueous gelatin solution, heat in a water bath at 38°C and stir thoroughly until the water evaporates to about 6mL to obtain a paste mixture ;

[0048] (3) After adding 1.5 mL of carbodiimide with a concentration of 1.5% and 3 mg of heparin into the paste mixture, stir it evenly and pour it into the microneedle template prepared in step (1), centrifuge at 7000 rpm for 15 min, and wait for After the pasty mixture fills the mold cavity, remove excess pasty mixture on the surface of the template;

[0049] (4) At room temperature, drop 5 mL of a mixed solution consisting of 15% gelatin and 240 μL of 1.25% glutaraldehyde above the mold cavity;

[0050] (5) After the mixed solution completely covered the surface of the mold cavity, the microneedle template was placed in a ventilated place to air dry natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com