Method for self-assembling and synthesizing spherical gold nanoparticles by using bacitracin as template

A technology for self-assembly of gold nanoparticles and templates, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Clear amino acid sequence, simple preparation method and green reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

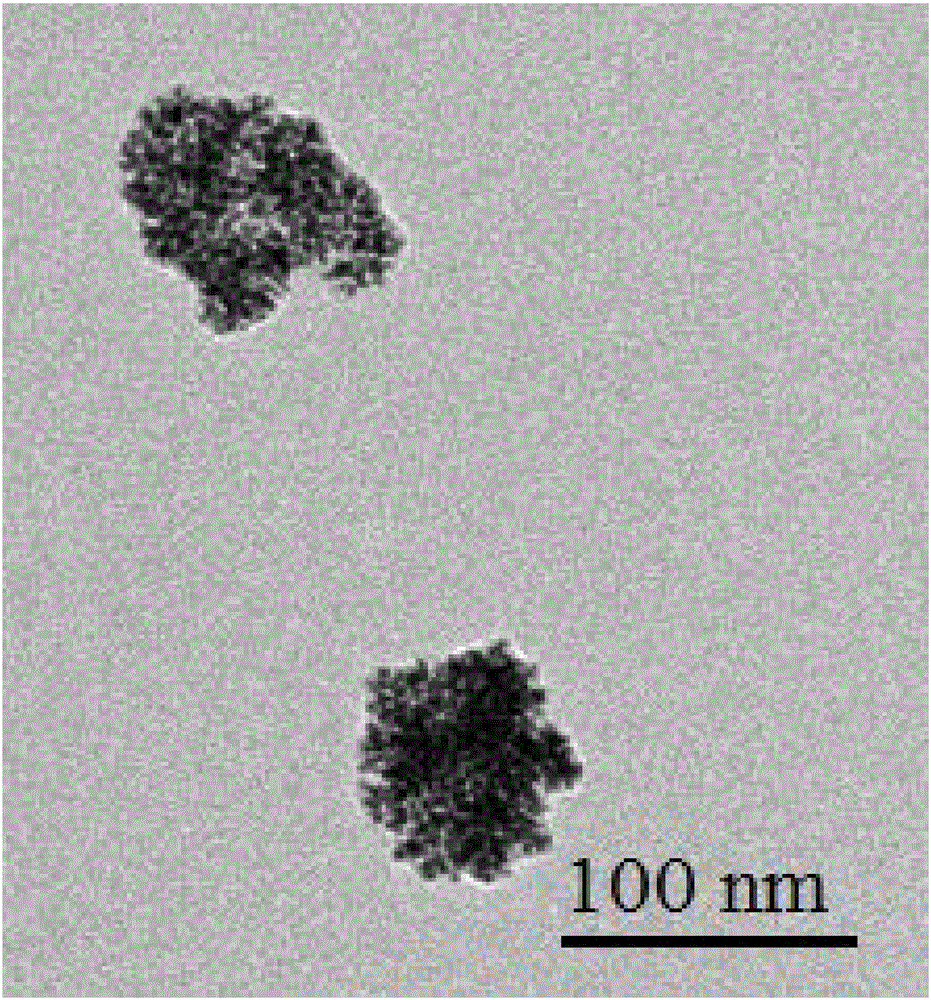

[0022] Take 0.5mg of bacitracin (Hubei Haiyi Pharmaceutical Chemical Co., Ltd.), and dissolve it in 1mL of pH 3 hydrochloric acid solution to prepare a 0.35mM bacitracin solution; take 200mL of the above bacitracin solution and heat-treat it in a metal bath at 40°C for 1h , and then ultrasonic treatment for 30s, the ultrasonic frequency is 50Hz; the treated bacitracin solution was mixed with 200mL 2mM AuCl 3 The solution (Shanghai West Asia Reagent Co., Ltd.) was mixed; the above-mentioned mixed solution was placed in a double-layer gas shaker, incubated at 100rmp, 20°C for 20h, and then 4mM reducing agent sodium borohydride (Tianjin Guangfu Fine Chemical Research Institute) was added. 60mL was reduced, the dropping rate was 1 drop / min, 30mL / drop, the reaction temperature was controlled at 21°C, and the reaction was carried out for 40min. The color of the solution slowly changed from golden yellow to blue-gray, and bacitracin-spherical gold nanoparticles were obtained.

[0023...

Embodiment 2

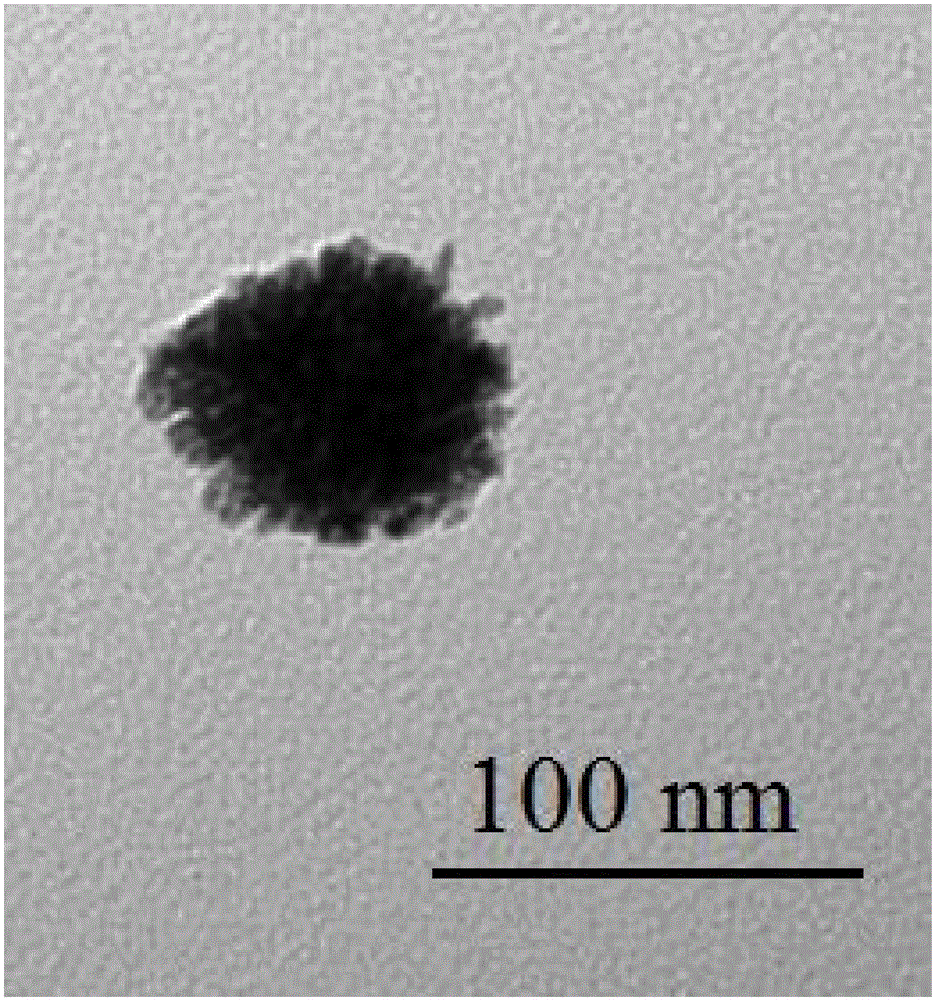

[0025] Take 0.75mg of bacitracin (Hubei Haiyi Pharmaceutical Chemical Co., Ltd.), and dissolve it in 1mL of hydrochloric acid solution with pH 3.5 to obtain a 0.53mM bacitracin solution; take 200mL of the above-mentioned bacitracin solution and heat-treat it in a metal bath at 50°C for 1.5 h, and then ultrasonic treatment for 30s, the ultrasonic frequency is 50Hz; the treated bacitracin solution was mixed with 200mL of 4mM 3 The solution (Shanghai West Asia Reagent Co., Ltd.) was mixed; the above-mentioned mixed solution was placed in a double-layer gas shaker, incubated at 125rmp and 22°C for 25h, and then 5mM reducing agent sodium borohydride (Tianjin Guangfu Fine Chemical Research Institute) was added. 60mL was reduced, the dropping rate was 1 drop / min, 30mL / drop, the reaction temperature was controlled at 22°C, and the reaction was carried out for 50min. The color of the solution slowly changed from golden yellow to blue-gray, and bacitracin-spherical gold nanoparticles wer...

Embodiment 3

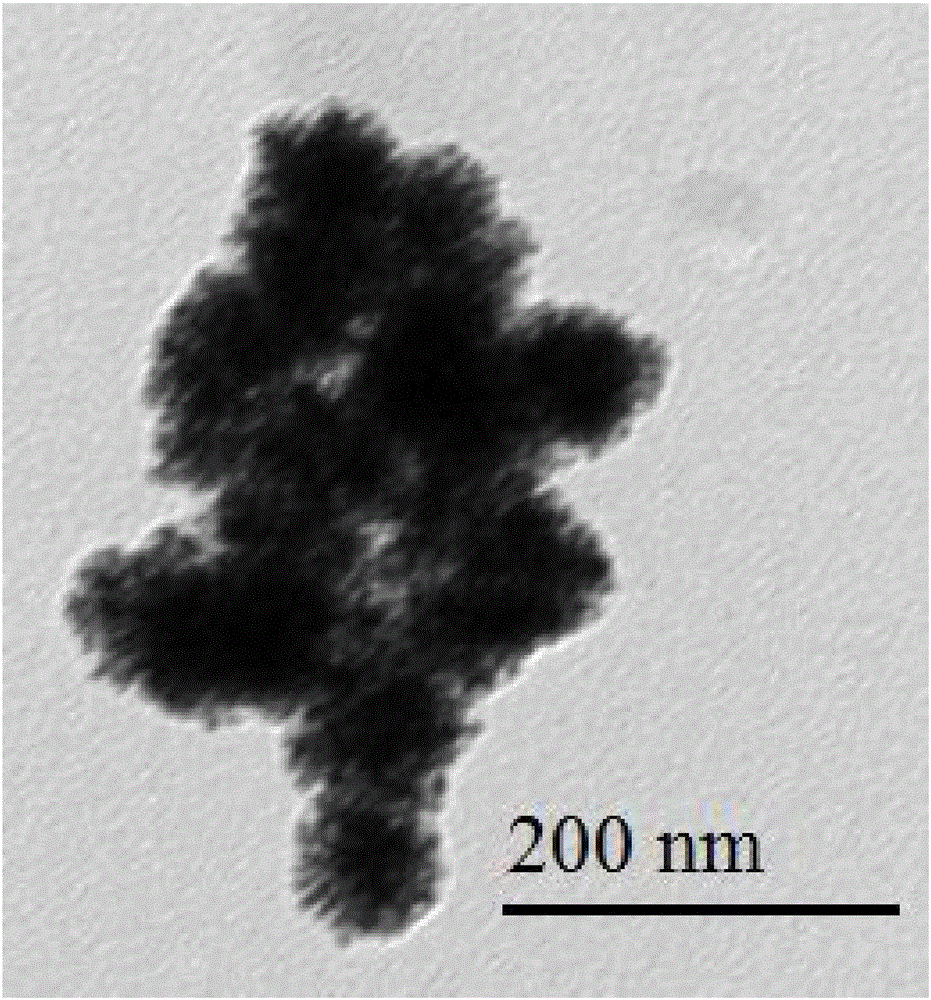

[0028] Take 1.0mg of bacitracin (Hubei Haiyi Pharmaceutical Chemical Co., Ltd.), and dissolve it in 1mL of pH 4 hydrochloric acid solution to prepare a 0.70mM bacitracin solution; take 200mL of the above bacitracin solution and heat-treat it in a metal bath at 60°C for 2h , and then ultrasonic treatment for 30s, the ultrasonic frequency is 50Hz; the treated bacitracin solution was mixed with 200mL 6mM AuCl 3 The solution (Shanghai West Asia Reagent Co., Ltd.) was mixed; the above-mentioned mixed solution was placed in an air bath shaker, incubated at 150rmp and 25°C for 30h, and then 6mM reducing agent sodium borohydride (Tianjin Guangfu Fine Chemical Research Institute) was added. ) 90mL for reduction, the dropping rate was 2 drops / min, 30mL / drop, the reaction temperature was controlled at 23°C, and the reaction was carried out for 60min. The color of the solution slowly changed from golden yellow to blue-gray, and bacitracin-gold nanoparticles were obtained.

[0029] Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com