Aqueous slurry of nanoscale calcium carbonate and its preparation method and application

A nano-scale calcium carbonate and nano-calcium carbonate technology, applied in the field of materials, can solve the problems of limited transparent wood paint, instability, limited application, etc., and achieve the effects of good stability, uniform dispersion and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

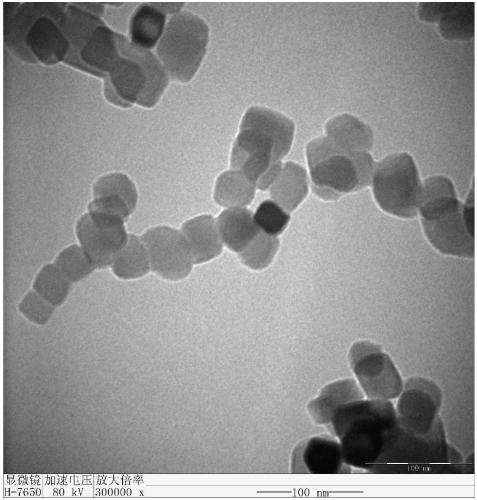

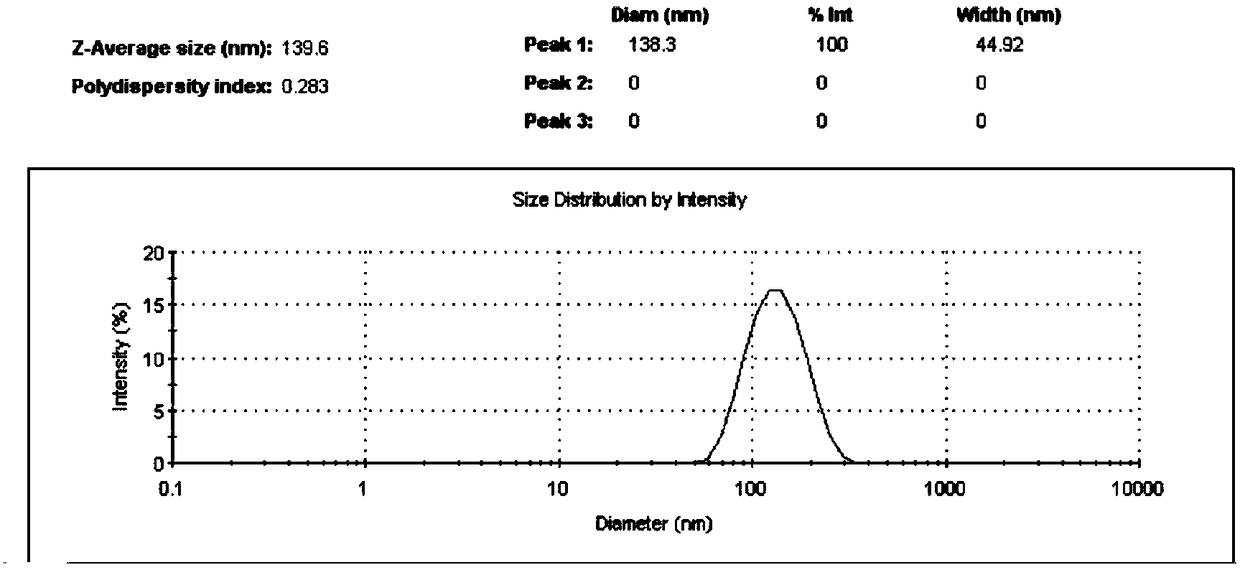

Image

Examples

Embodiment 1

[0031] Put 27.97g of quicklime into 280g of water at 80°C, and digest it at 1000rpm with a dispersing disc for 2h. Pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, add water to prepare a 12wt% calcium hydroxide suspension, age for 24 hours, and set aside.

[0032] Calcium hydroxide suspension is dispersed with dispersing disc 1000rpm line cutting, adds 0.6wt% dilute sulfuric acid solution and 2wt% polyethylene glycol 400 (mass percentage of calcium carbonate theoretical yield), controls carbonization temperature and is less than 15 ℃, from the bottom into CO 2 / N 2 Mixed gas (60 / 120m 3 h -1 m -3 Suspension liquid), carbonized, carbonized to pH = 7, and then the reaction solution was filtered and washed.

[0033] The above-mentioned calcium carbonate and water are mixed into a 40wt% slurry, sanded in a circulating sand mill, and 3.4wt% sodium polyacrylate is added before the sanding, and sanded for 10 minutes to obtain a nano-calcium carbon...

Embodiment 2

[0035] Put 27.97g of quicklime into 280g of water at 80°C and digest it for 4h with a dispersing disc at 1000rpm. Pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, add water to prepare a 12wt% calcium hydroxide suspension, age for 24 hours, and set aside.

[0036] Calcium hydroxide suspension is dispersed with dispersing disk 1000rpm line cutting, adds 1.5wt% sodium silicate solution and 3wt% polyethylene glycol 600 (mass percentage of calcium carbonate theoretical yield), controls carbonization temperature less than 15 ℃, from Bottom into CO 2 / N 2 Mixed gas (40 / 120m 3 h -1 m -3 Suspension liquid), carbonized, carbonized to pH = 7, and then the reaction solution was filtered and washed.

[0037] Mix the above-mentioned calcium carbonate with water to form a 20wt% slurry, sand it in a circulating sand mill, add 2.2wt% sodium hexametaphosphate before sanding, and sand it for 15 minutes to obtain a nano-calcium carbonate slurry with an averag...

Embodiment 3

[0039] Put 22.95g of quicklime into 280g of water at 80°C, and digest it at 1000rpm with a dispersion plate for 3h. Pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, add water to prepare a 10 wt% calcium hydroxide suspension, age for 24 hours, and set aside.

[0040] Calcium hydroxide suspension is dispersed with dispersing disc 1000rpm line cutting, adds 1.0wt% dilute sulfuric acid solution and 4wt% polyethylene glycol 600 (mass percentage of calcium carbonate theoretical yield), controls carbonization temperature to be less than 15 ℃, from the bottom into CO 2 / N 2 Mixed gas (60 / 120m 3 h -1 m -3 Suspension liquid), carbonized, carbonized to pH = 7, and then the reaction solution was filtered and washed.

[0041] The above-mentioned calcium carbonate is mixed with water to form a 10wt% slurry, sanded in a circulating sand mill, and 3.0wt% sodium polyacrylate is added before sanding, and sanded for 20 minutes to obtain a nano-calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com