Resourceful treatment method for fused salt chlorination residues

A molten salt chlorination slag and treatment method technology, applied in the direction of titanium tetrachloride, titanium halide, process efficiency improvement, etc., can solve the problems of difficult industrial application, large material consumption, high cost, etc., to solve pollution problems, The process is simple and the effect of eliminating the development bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

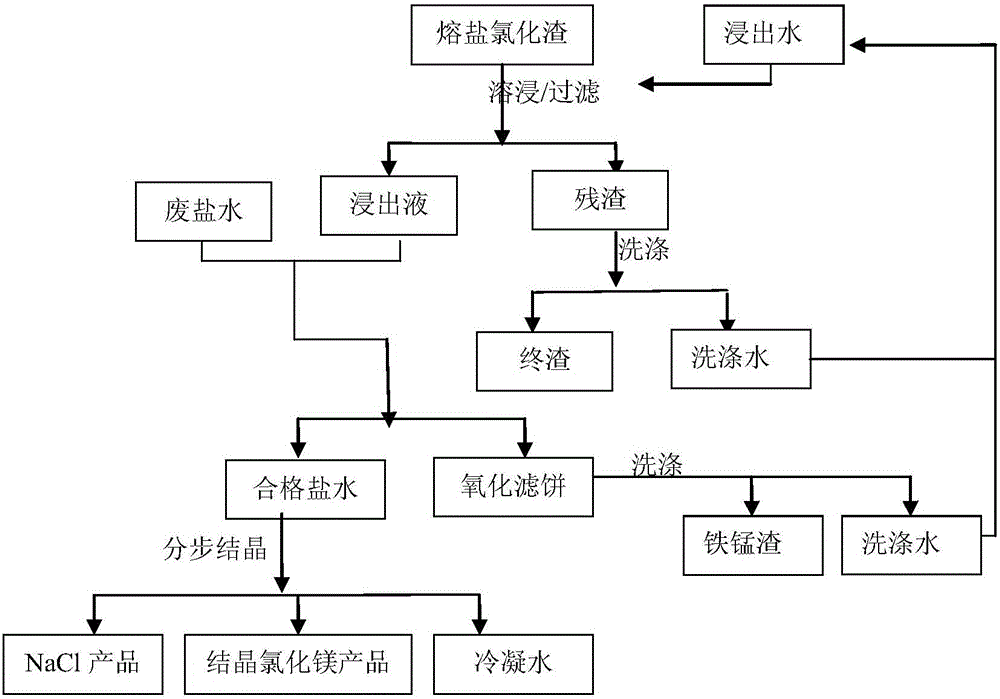

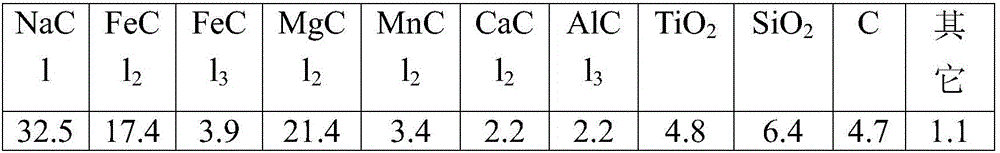

[0028] The composition of the molten salt chlorinated slag crushed material to be recycled in this embodiment is shown in Table 1.

[0029] Table 1 Composition analysis results of molten salt chlorination slag

[0030]

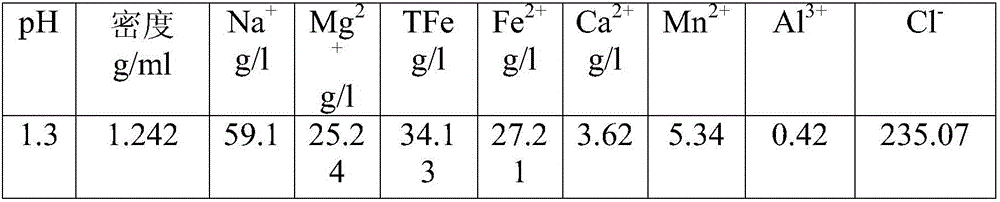

[0031] Firstly, the molten salt chlorinated residue is leached to obtain a slurry, and then filtered to obtain the leachate and the leaching residue. The water quality analysis results of the leachate are shown in Table 2.

[0032] Table 2 Water quality analysis results of leachate

[0033]

[0034] The leaching residue is washed with water until the salt content is less than 1.0%, and the liquid-solid ratio is about 3.0:1 during washing. After washing, the final slag is obtained, and the final slag is buried. The final slag composition analysis results are shown in Table 3.

[0035] Table 3 Analysis results of final slag composition

[0036]

[0037] Purify the leaching liquid and molten salt chlorination tail gas containing NaCl, NaClO, Na 2 CO 3 The strong oxidizin...

Embodiment 2

[0049] The specific method for resource treatment of molten salt chlorinated slag in this embodiment is basically the same as that in Example 1, but the leachate is oxidized with the chlor-alkali plant waste liquid shown in Table 10, and the dosage ratio of the waste liquid is 0.87 times the volume of the leachate.

[0050] The composition of the molten salt chlorinated slag crushed material to be recycled in this embodiment is shown in Table 7.

[0051] Table 7 Composition analysis results of molten salt chlorinated slag

[0052]

[0053] The water quality analysis results of the leachate are shown in Table 8.

[0054] Table 8 Water quality analysis results of leachate

[0055]

[0056] The leaching residue was washed with tap water with a liquid-to-solid ratio of 3.0:1, and the final residue composition analysis results are shown in Table 9.

[0057] Table 9 Analysis results of final slag composition

[0058]

[0059] The leachate is oxidized with the waste liquid of the chlor-alkali pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com