Preparation method of water body denitrification material

A technology for denitrification and water body, applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc. The nitrifying bacteria have strong activity, high utilization efficiency and good particle forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

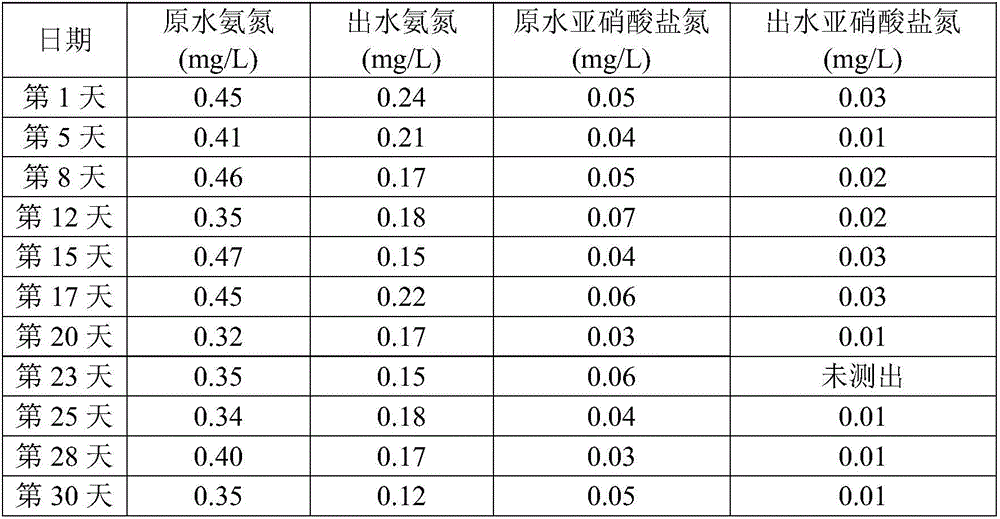

Embodiment 1

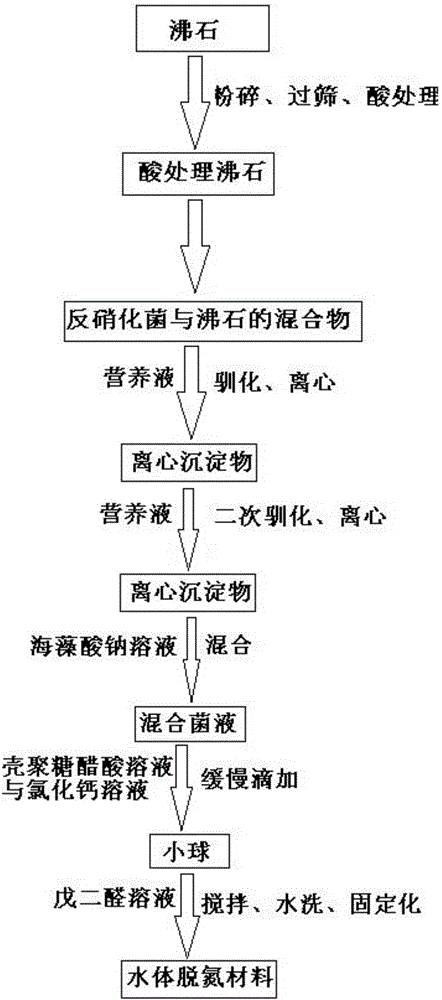

[0032] Such as figure 1 As shown, the preparation method of the water body denitrification material of the present embodiment comprises the following steps:

[0033] (1) Get the natural zeolite to grind and pulverize, then pass through a 100-mesh sieve, and the obtained sieved zeolite is immersed in 0.1mol / L hydrochloric acid solution for 2h, and then washed with deionized water until neutral;

[0034] (2) Soak the zeolite treated with hydrochloric acid in step (1) with 1 g / L lysozyme aqueous solution for 12 hours, and then wash it with deionized water for 3 times.

[0035] (3) Mix the powdery denitrifying bacteria with the zeolite treated with lysozyme in step (2) according to the mass ratio of 1:20 and then add it into the Erlenmeyer flask; weigh 4g KNO 3 , 4g NaNO 3 , 0.05g MgSO 4 ·7H 2 O, 1.85g K 2 HPO 4 , 8g potassium sodium tartrate, 1g KH 2 PO 4 , 1g FeCl 2 , 1g CaCl 2 2H 2 0, 0.5g cysteine and 54.06g glucose, add deionized water to dissolve and be constant...

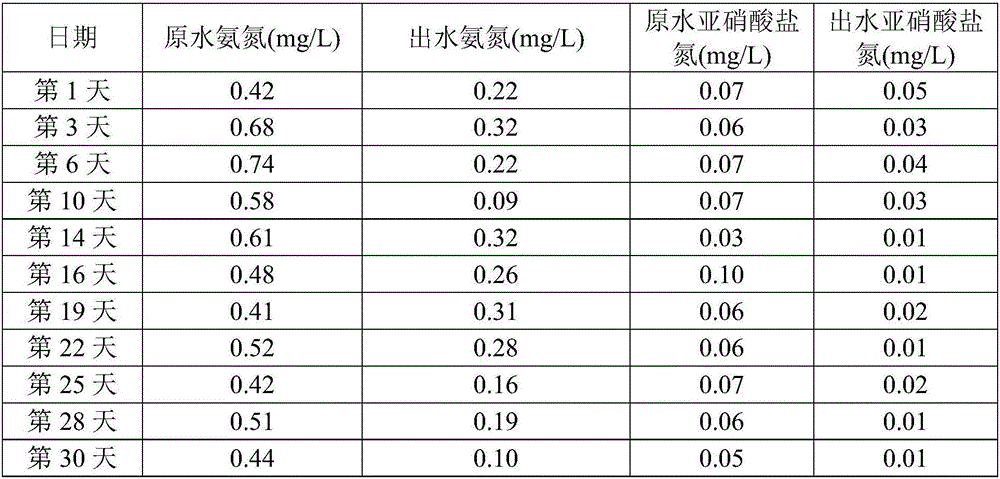

Embodiment 2

[0044] Such as figure 1 As shown, the preparation method of the water body denitrification material of the present embodiment comprises the following steps:

[0045] (1) Get the natural zeolite to grind and pulverize, then pass through a 100-mesh sieve, and the obtained sieved zeolite is immersed in 0.1mol / L hydrochloric acid solution for 2h, and then washed with deionized water until neutral;

[0046] (2) Soak the zeolite treated with hydrochloric acid in step (1) with 1 g / L lysozyme aqueous solution for 12 hours, and then wash it with deionized water for 3 times.

[0047] (3) Mix the powdered denitrifying bacteria with the lysozyme-treated zeolite in step (2) according to the mass ratio of 1:30 and then add it into the Erlenmeyer flask; weigh 4g KNO 3 , 4g NaNO 3 , 0.05g MgSO 4 ·7H 2 O, 1.85g K 2 HPO 4 , 8g potassium sodium tartrate, 1g KH 2 PO 4 , 1g FeCl 2 , 1g CaCl 2 2H 2 0, 0.5g cysteine and 54.06g glucose, add deionized water to dissolve and be constant to ...

Embodiment 3

[0056] Such as figure 1 As shown, the preparation method of the water body denitrification material of the present embodiment comprises the following steps:

[0057] (1) Get the natural zeolite to grind and pulverize, then pass through a 100-mesh sieve, and the obtained sieved zeolite is immersed in 0.1mol / L hydrochloric acid solution for 2h, and then washed with deionized water until neutral;

[0058] (2) Soak the zeolite treated with hydrochloric acid in step (1) with 1 g / L lysozyme aqueous solution for 12 hours, and then wash it with deionized water for 3 times.

[0059] (3) Mix the powdered denitrifying bacteria with the zeolite treated with lysozyme in step (2) according to the mass ratio of 1:40 and then add it into the Erlenmeyer flask; weigh 4g KNO 3 , 4g NaNO 3 , 0.05g MgSO 4 ·7H 2 O, 1.85g K 2 HPO 4 , 8g potassium sodium tartrate, 1g KH 2 PO 4 , 1g FeCl 2 , 1g CaCl 2 2H 2 0, 0.5g cysteine and 54.06g glucose, add deionized water to dissolve and be constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com