Automobile coating sewage treatment process

A technology for coating sewage and treatment process, applied in biological water/sewage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. , complex components, etc., to achieve good sewage purification effect, ensure stability, and prevent clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

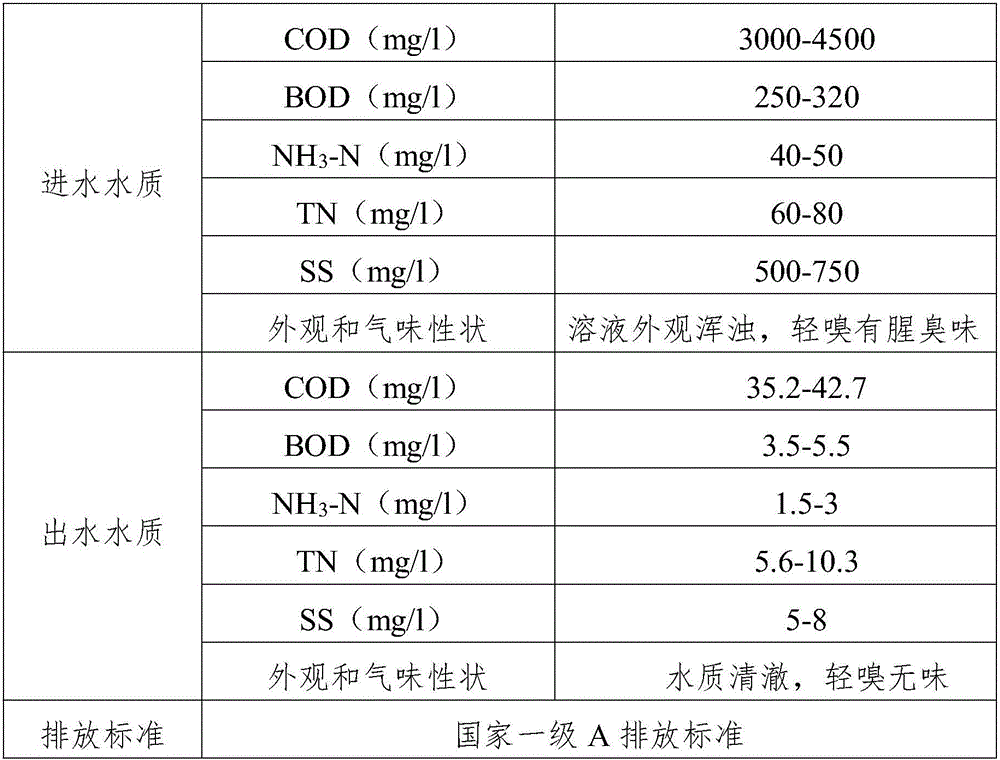

Examples

Embodiment 1

[0025] A kind of automobile painting sewage treatment process, comprises the steps:

[0026] S1. Preprocessing:

[0027] Demulsification: add AP demulsifier to the sewage at the input amount of 4.5mg / L, and demulsify the sewage by electro-precipitation method;

[0028] Coagulation: adjust the pH of the sewage to 10.3, make the sewage flow into the reaction tank, and stay in the tank for 14 minutes;

[0029] air flotation;

[0030] S2. Passing through the grid: put flocculant into the grid tank according to the input amount of 1g / L, settle for 1h, pass the sewage first through the grid of 3-5cm, and then through the grid of 0.2-1cm to remove the floc;

[0031] S3. Through the O / A / O composite biological filter: the sewage is passed into the O / A / O composite biological filter with a small lightweight porous carrier, and the organic pollutants and suspended particles in the sewage pass through the carrier. microbial adsorption, retention and degradation;

[0032] S4. Activated ...

Embodiment 2

[0037] A kind of automobile painting sewage treatment process, comprises the steps:

[0038] S1. Preprocessing:

[0039] Demulsification: According to the input amount of 6mg / L, AR type demulsifier is added to the sewage, and the sewage is demulsified by the electrodeposition method;

[0040] Coagulation: adjust the pH of the sewage to 9.4, make the sewage flow into the reaction tank, and stay in the tank for 12 minutes;

[0041] air flotation;

[0042] S2. Passing through the grid: put flocculant into the grid tank according to the input amount of 1.5g / L, settle for 1.5h, pass the sewage first through the grid of 3-5cm, and then through the grid of 0.2-1cm to remove the floc;

[0043] S3. Through the O / A / O composite biological filter: the sewage is passed into the O / A / O composite biological filter with a small lightweight porous carrier, and the organic pollutants and suspended particles in the sewage pass through the carrier. microbial adsorption, retention and degradatio...

Embodiment 3

[0049] A kind of automobile painting sewage treatment process, comprises the steps:

[0050] S1. Preprocessing:

[0051] Demulsification: add AP type demulsifier to the sewage according to the input amount of 6mg / L, and demulsify the sewage by electrodeposition method;

[0052] Coagulation: adjust the pH of the sewage to 9.8, make the sewage flow into the reaction tank, and stay in the tank for 16 minutes;

[0053] air flotation;

[0054] S2. Passing through the grid: put flocculant into the grid tank according to the input amount of 0.5g / L, settle for 2 hours, pass the sewage first through the grid of 3-5cm, and then through the grid of 0.2-1cm to remove the floc;

[0055] S3. Through the O / A / O composite biological filter: the sewage is passed into the O / A / O composite biological filter with a small lightweight porous carrier, and the organic pollutants and suspended particles in the sewage pass through the carrier. microbial adsorption, retention and degradation;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com