Preparation method of zirconium diboride powder

A technology of zirconium diboride and zirconium dioxide powder is applied in the field of preparation of zirconium diboride ceramic powder, which can solve the problems of low production cost, low reaction efficiency, coarse product particles and the like, and achieves fast heating speed and high purity. High, complete product conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of zirconium diboride powder, which comprises the steps of:

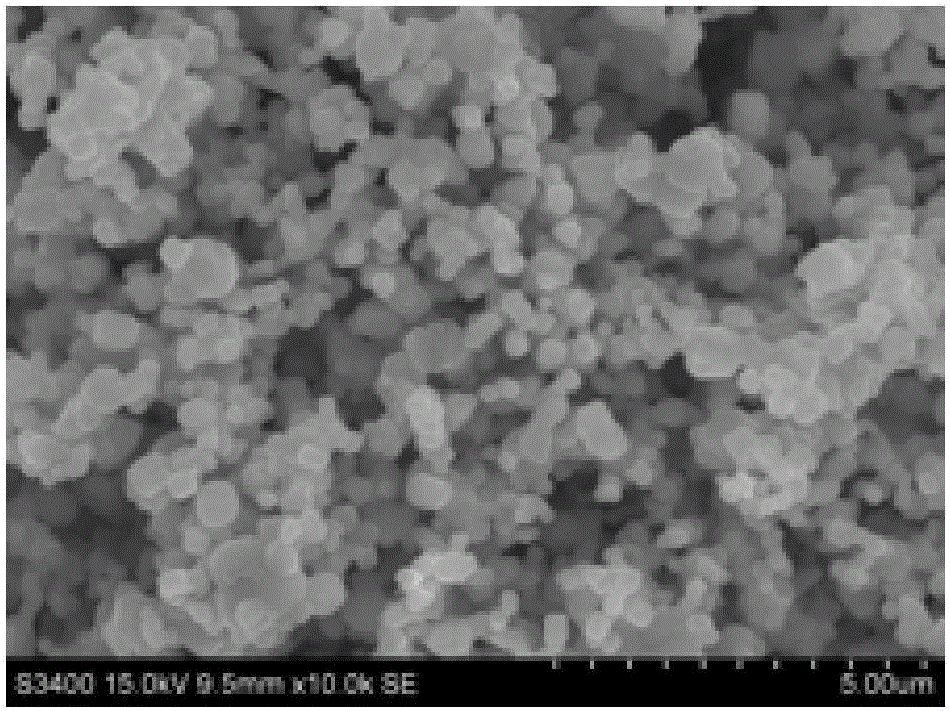

[0022] Zirconia powder (50nm), amorphous boron powder (1μm), amorphous carbon powder (50nm) and boron carbide powder (1μm) are selected as raw materials, x is 0.1, y is 0.1, and the total molar ratio is 0.4:1: 0.1:0.1, planetary ball milling for 6 hours, the ball milling balls are zirconia balls (diameter 5mm), the medium is ethanol, the ball milling speed is 200 rpm; after ball milling, filter, pour the filtered liquid into a pear-shaped bottle, and rotate at 60°C Evaporate for 0.5h, dry for 48h (dried at 60°C), grind and sieve (325 mesh) to get a uniformly mixed mixed powder (or called raw material powder); put the mixed powder in a graphite reactor, and the graphite reacts Put the device into a high-current reaction synthesis device, evacuate to below 10Pa, start heating (200K / min), heat up to 1400°C and keep warm for 3 minutes to obtain a powder sample; take out the synthesized powder...

Embodiment 2

[0024] A preparation method of zirconium diboride powder, which comprises the steps of:

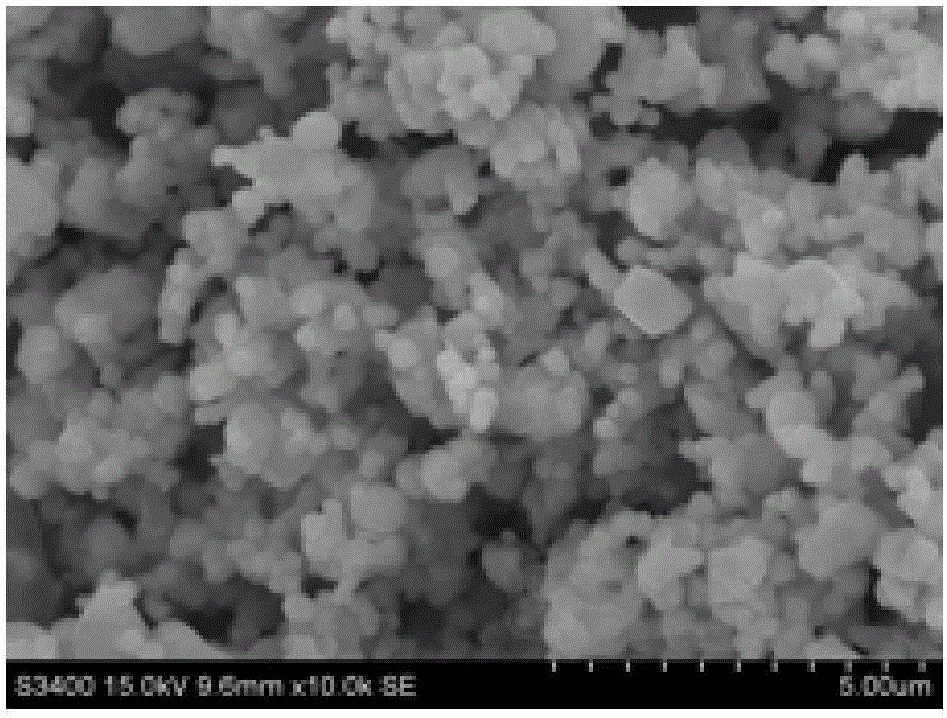

[0025] Choose zirconia powder (50nm), amorphous boron powder (1μm), amorphous carbon powder (50nm) and boron carbide powder (1μm) as raw materials, x is 0.1, y is 0.5, and the total molar ratio is 0.9:1 : 0.1: 0.5, planetary ball milling for 6 hours, ball milling balls are zirconia balls (diameter 5mm), medium is ethanol, ball milling speed is 200 rpm; filter after ball milling, pour the filtered liquid into a pear-shaped bottle, and store at 60°C Rotary evaporation for 0.5h, drying for 48h (drying at 60°C), grinding and sieving (325 mesh) to obtain a uniformly mixed mixed powder; put the mixed powder in a graphite reactor, and put the graphite reactor into a high-current reaction In the synthesis device, evacuate to below 10Pa, start to heat up (300K / min), heat up to 1400°C and keep it warm for 5 minutes to obtain a powder sample; take out the synthesized powder sample, wash it in hot wa...

Embodiment 3

[0027] A preparation method of zirconium diboride powder, which comprises the steps of:

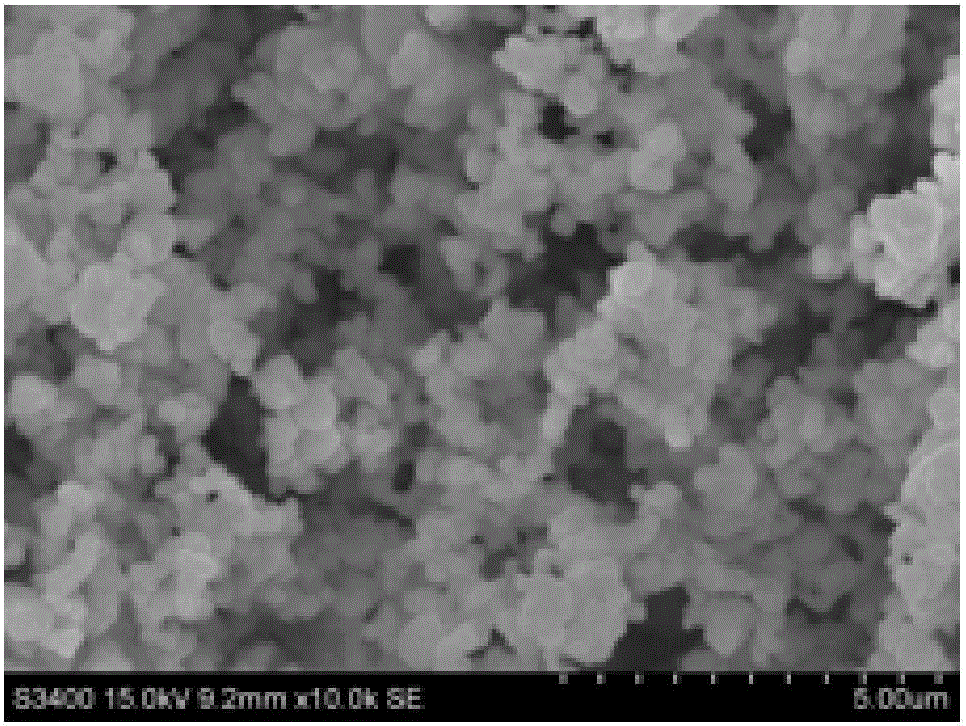

[0028] Zirconia powder (50nm), amorphous boron powder (1μm), amorphous carbon powder (50nm) and boron carbide powder (1μm) are selected as raw materials, x is 0.33, y is 0.1, and the total molar ratio is 0.46:1: 0.33:0.1, planetary ball milling for 6 hours, ball milling balls are zirconia balls (diameter 5mm), medium is ethanol, ball milling speed is 200 rpm; filter after ball milling, pour the filtered liquid into a pear-shaped bottle, and rotate at 60°C Evaporate for 0.5h, dry for 48h (dry at 60°C), grind and sieve (325 mesh) to get a uniform mixed powder; put the mixed powder in a graphite reactor, and put the graphite reactor into a high-current reaction synthesis In the device, evacuate to below 10Pa, start to heat up (500K / min), heat up to 1500°C and keep warm for 3 minutes to obtain a powder sample; take out the synthesized powder sample, wash it in 80°C hot water for 2h, filter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap