Method for realizing green synthesis of 2-substituted benzothiazole derivatives

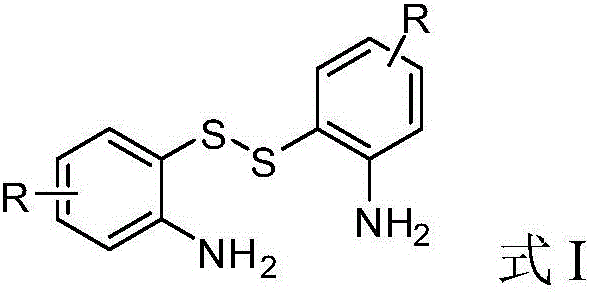

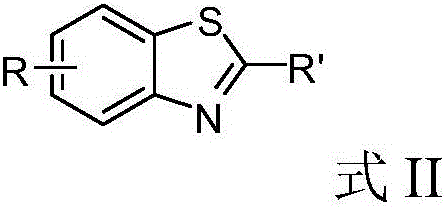

A technology for benzothiazoles, green synthesis, applied in the direction of organic chemistry and the like, can solve the problems of unstable o-aminothiophenol, high cost of raw material preparation, long synthesis steps, etc., and achieves short steps, high yield and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

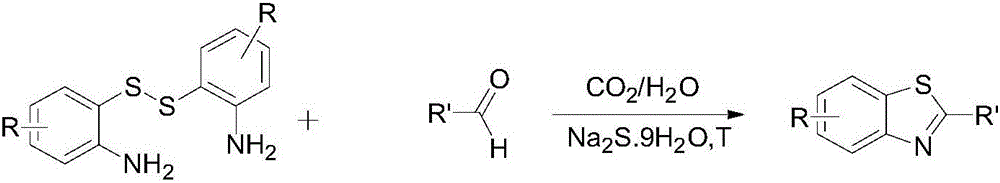

[0029] Embodiment 1: take benzaldehyde as raw material to synthesize 2-phenylbenzothiazole

[0030] (1) Synthesis of 2-phenylbenzothiazole

[0031] a: Disulfide: Aldehyde: Na 2 S·9H 2 O=1:2:0.2

[0032] In the autoclave, add 0.40mmol of 2,2'-dithiodiphenylamine, 0.80mmol of benzaldehyde and 0.08mmol of Na 2 S·9H 2 O, put the magneton, then add 2 mL of water as the reaction solvent, heat it to 50 °C, and then fill with 2 MPa of carbon dioxide gas. Then continue to heat up to 80°C and stir for 24h. LC detection finds that the reaction of the disulfide raw materials is complete, cool to room temperature, and use a rotary evaporator to remove the solvent under reduced pressure to obtain a crude product. Using petroleum ether and ethyl acetate as eluents, the crude product was eluted with a gradient, and separated by column chromatography (200-300 mesh silica gel) to obtain 121.5 mg of 2-phenylbenzothiazole as a white powder with a purity of more than 99%. , the isolated yiel...

Embodiment 2

[0044] Example 2: Synthesis of 2-(4-chlorophenyl) benzothiazole with p-chlorobenzaldehyde as raw material

[0045] (1) Synthesis of 2-(4-chlorophenyl)benzothiazole

[0046] In the autoclave, add 0.40mmol of 2,2'-dithiodiphenylamine, 0.80mmol of p-chlorobenzaldehyde and 0.2mmol of Na 2 S·9H 2 O, put the magneton, then add 2 mL of water as the reaction solvent, heat it to 50 °C, and then fill with 2 MPa of carbon dioxide gas. Then continue to heat up to 80°C and stir for 24h. LC detection finds that the reaction of the disulfide raw materials is complete, cool to room temperature, and use a rotary evaporator to remove the solvent under reduced pressure to obtain a crude product. Using petroleum ether and ethyl acetate as eluents, the crude product was eluted with a gradient and separated by column chromatography (200-300 mesh silica gel) to obtain 2-(4-chlorophenyl) as a white powder with a purity greater than 99%. Benzothiazole 139.2 mg, isolated yield 71%, mp 112-113°C.

...

Embodiment 3

[0052] Embodiment 3: take p-bromobenzaldehyde as raw material to synthesize 2-(4-bromophenyl) benzothiazole

[0053] (1) Synthesis of 2-(4-bromophenyl)benzothiazole

[0054] In the autoclave, add 0.40mmol of 2,2'-dithiodiphenylamine, 0.80mmol of p-bromobenzaldehyde and 0.2mmol of Na 2 S·9H 2 O, put the magneton, then add 2 mL of water as the reaction solvent, heat it to 50 °C, and then fill with 2 MPa of carbon dioxide gas. Then continue to heat up to 80°C and stir for 24h. LC detection finds that the reaction of the disulfide raw materials is complete, cool to room temperature, and use a rotary evaporator to remove the solvent under reduced pressure to obtain a crude product. Using petroleum ether and ethyl acetate as eluents, the crude product was eluted with a gradient and separated by column chromatography (200-300 mesh silica gel) to obtain 2-(4-bromophenyl) as a white powder with a purity greater than 99%. Benzothiazole 187.2 mg, isolated yield 81%, mp 126-128°C.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com