Quaternary ammonium salt group containing polysiloxane block copolymer and preparation method and application

A technology of polysiloxane block and quaternary ammonium salt group, which is applied in the field of synthetic polymer biomaterials, and can solve the problem of weak ability to prevent and control fungus on the surface of plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

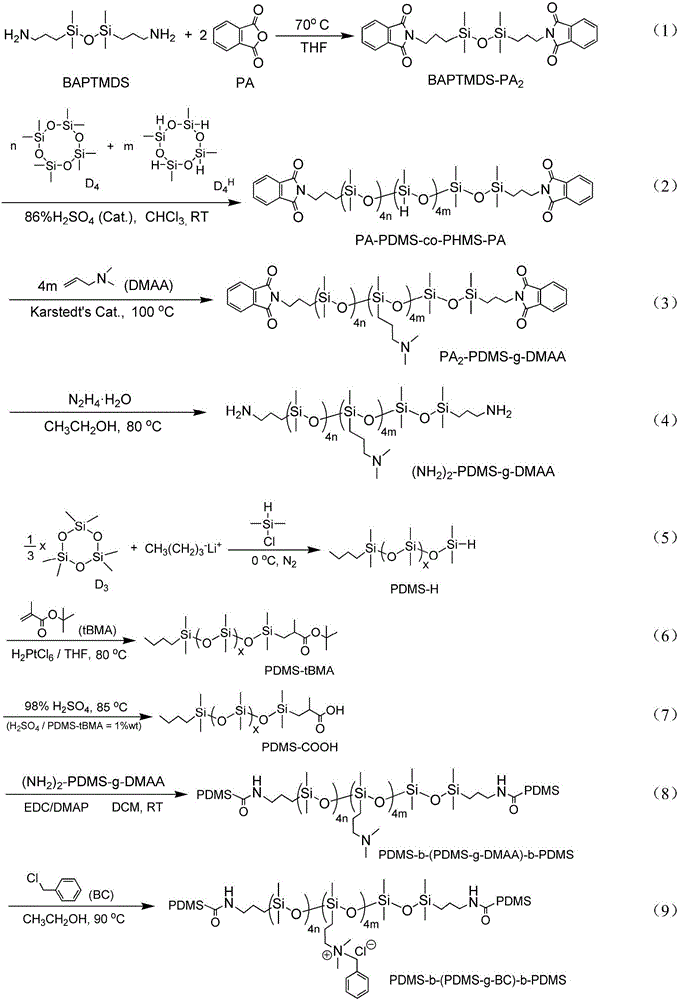

Method used

Image

Examples

Embodiment 1

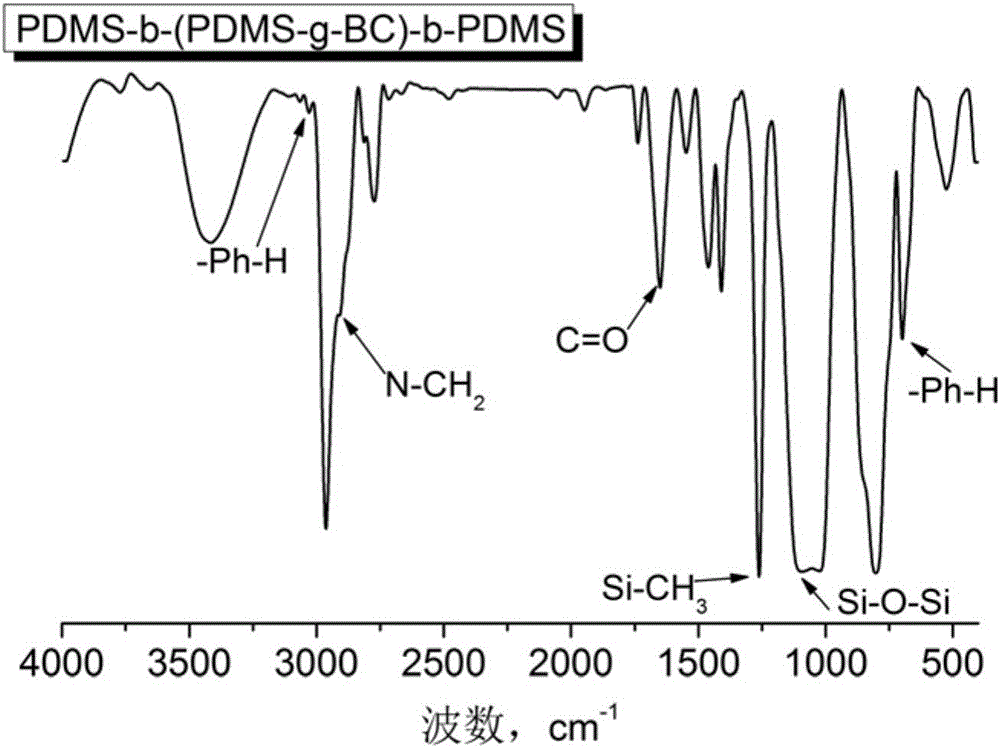

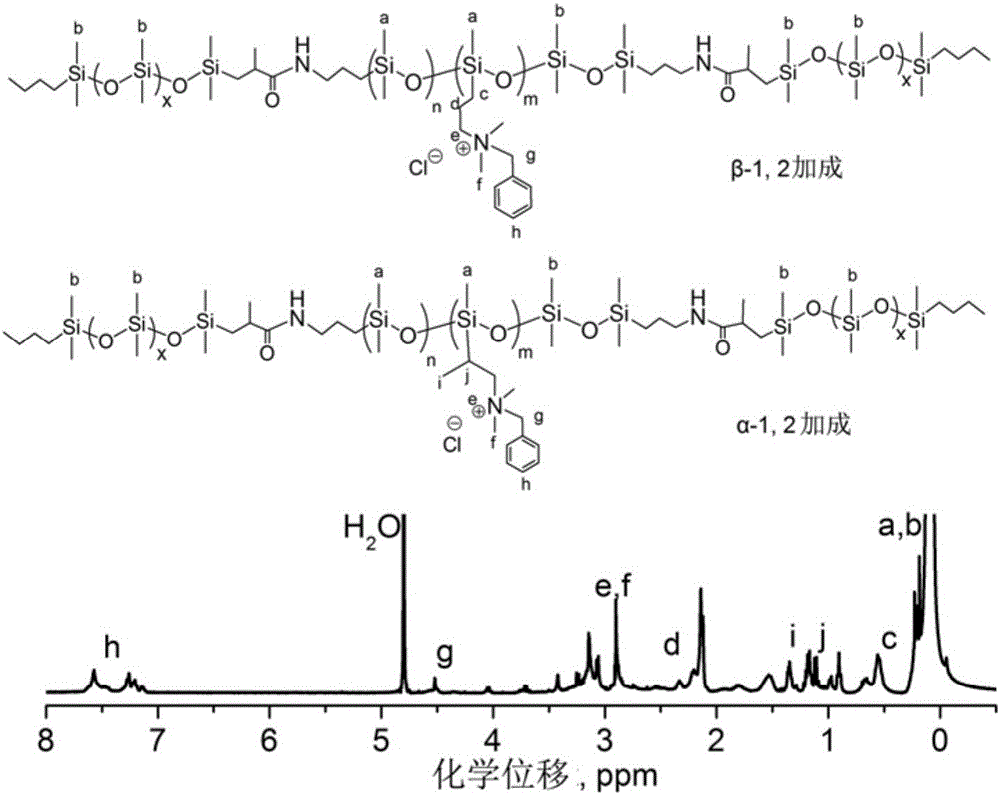

[0094] The preparation of the polysiloxane block copolymer containing quaternary ammonium salt group: the segment length ratio is PDMS: PDMS-g-BC: PDMS=1: 4: 1, the block containing quaternary ammonium salt group (PDMS -g-BC), the proportion (grafting ratio) of the total number of chain members grafted with quaternary ammonium salt groups is 1 / 5, and the halogenated hydrocarbon is benzyl chloride.

[0095] (1) Protection of aminodisiloxane head (BAPTMDS): in the reaction kettle equipped with mechanical stirring and condenser, feed according to the molar ratio of raw materials BAPTMDS: phthalic anhydride = 1: 2.2, use the total amount of raw materials The raw materials were dissolved in tetrahydrofuran twice the mass, and reacted at 60°C for 4 hours. After the reaction, the solvent THF was distilled off under reduced pressure, the product was dissolved in chloroform, the product was washed 5 times with hot water at 55°C, and the chloroform layer was distilled under reduced pres...

Embodiment 2

[0107] Preparation of polysiloxane block copolymer (PDMS-b-(PDMS-g-BB)-b-PDMS) containing grafted butyldimethylammonium chloride groups: the ratio of segment length is PDMS:PDMS -g-BB: PDMS=1:5:1, in the block (PDMS-g-BB) containing the quaternary ammonium salt group, the proportion of chain members grafted with the quaternary ammonium salt group to the total number of chain members ( Grafting ratio) is 1 / 4, and halogenated hydrocarbon is n-butane bromide.

[0108] (1) Protection of aminodisiloxane head (BAPTMDS): in the reaction kettle equipped with mechanical stirring and condenser, feed according to the raw material molar ratio BAPTMDS: phthalic anhydride = 1: 2.4, use the total raw material The raw material was dissolved in dichloromethane with twice the mass, and reacted at 70°C for 5 hours. After the reaction, the solvent THF was distilled off under reduced pressure, the product was dissolved in chloroform, the product was washed three times with hot water at 60°C, and ...

Embodiment 3

[0118] Preparation of polysiloxane block copolymer (PDMS-b-(PDMS-g-HEB)-b-PDMS) containing grafted hexyldimethylammonium bromide groups: the ratio of segment length is PDMS:PDMS- g-HEB: PDMS = 1:5:1, in the block containing quaternary ammonium salt groups, the proportion of chain members grafted with quaternary ammonium salt groups to the total number of chain members (grafting ratio) is 1 / 3 , The halogenated hydrocarbon is n-hexane bromide.

[0119] (1) Protection of aminodisiloxane head (BAPTMDS): In the reaction kettle equipped with mechanical stirring and condenser, feed according to the raw material molar ratio BAPTMDS: phthalic anhydride = 1: 2.6, and use the total raw material The raw materials were dissolved in tetrahydrofuran twice the mass, and reacted at 80°C for 6 hours. After the reaction, the solvent THF was distilled off under reduced pressure, the product was dissolved in chloroform, the product was washed 4 times with hot water at 65°C, and the chloroform lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com