Method for preparing cadmium compound quantum dot fluorescent thin film

A cadmium compound, quantum dot technology, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve problems such as application constraints, reduced efficiency, transparency, and poor compatibility, and achieve high light transmittance and high fluorescence. Quantum yield, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

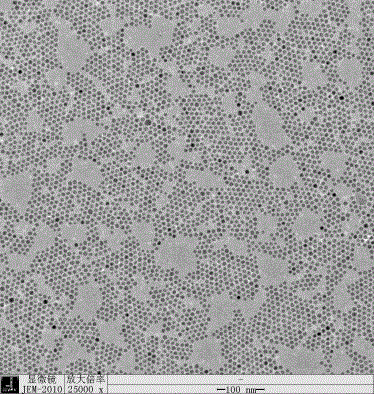

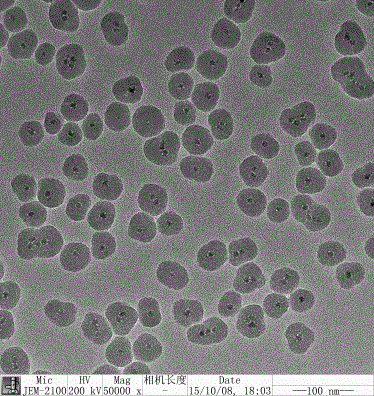

[0029] A preparation method of cadmium compound quantum dot fluorescent film includes the following steps:

[0030] ①Preparation of amphiphilic resin solution: heat alcohol ether solvent (propylene glycol methyl ether) to 100℃, and then add dropwise hydrophilic monomer (methacrylic acid), hydrophobic monomer (lauryl methacrylate), peroxide The mixed solution of benzoyl and toluene, after 3 hours of dripping, continue to react at 100°C for 2 hours to obtain an amphiphilic resin solution (abbreviated as APLMA);

[0031] ②Preparation of oil-soluble cadmium compound quantum dot non-polar solution: dissolve oil-soluble cadmium compound quantum dots in toluene to prepare an oil-soluble cadmium compound quantum dot non-polar solution;

[0032] ③Preparation of quantum dot aqueous solution: mix the oil-soluble cadmium compound quantum dot non-polar solution, amphiphilic resin solution and absolute ethanol in a volume ratio of 1:0.05:0.25 for 10 minutes, and add 28wt% concentrated ammonia (the...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that in the step ⑤, the polymer resin solution and the silica-coated quantum dot solution have a volume ratio of 1:2.

Embodiment 3

[0044] The difference between Example 3 and Example 1 is that in the step ⑤, the polymer resin solution and the silica-coated quantum dot solution have a volume ratio of 1:3.

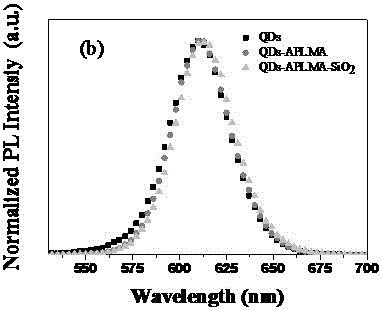

[0045] Figure 5 Is the fluorescence comparison chart of the quantum dot fluorescent film prepared in Example 1-3 (labeled as 1#, 2#, 3#, respectively), from Figure 5 It can be seen that as the amount of silica coated quantum dot solution increases, the amount of quantum dots in the film increases, and the fluorescence intensity increases; Image 6 Are the transmission spectra of the quantum dot fluorescent films prepared in Examples 1-3 (respectively labeled as 1#, 2#, 3#), from Image 6 It can be seen that the transparency of the quantum dot fluorescent film obtained in the present invention is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com