Method for brewing super-mature vinegar by adopting red yeast prepared from tartary buckwheat

A technology of tartary buckwheat, red yeast rice and mature vinegar, which is applied in the preparation of vinegar, medical formulas, medical preparations containing active ingredients, etc., and can solve the problems of single use of tartary buckwheat or red yeast rice and insufficient utilization of tartary buckwheat resources, etc. Achieve the effect of improving color and flavor, enriching microbial flora and enzyme system, and enhancing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

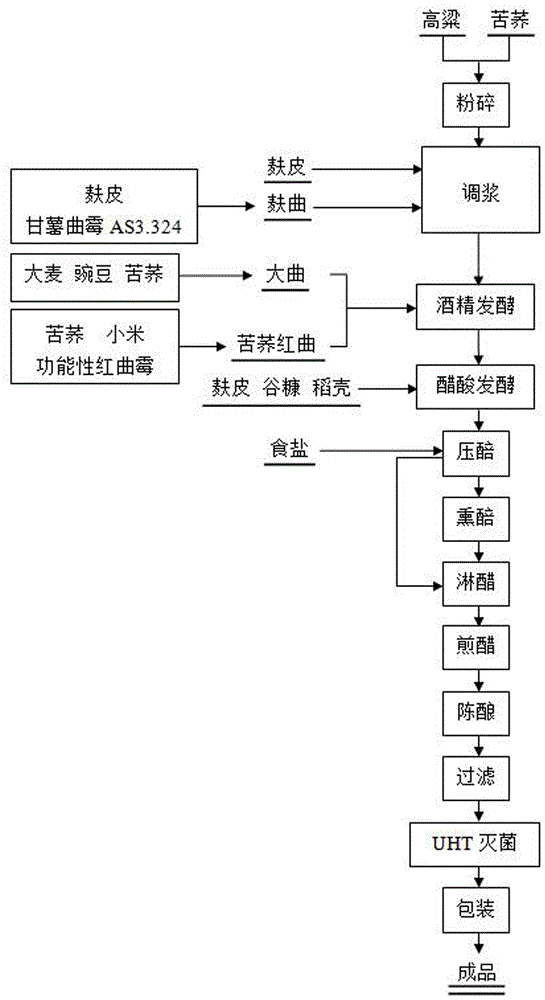

[0052] A brewing method of tartary buckwheat and red yeast rice vinegar, comprising the steps of:

[0053] 1. Koji making

[0054] a. Preparation of Tartary Buckwheat Daqu

[0055] Add tartary buckwheat to the original raw materials of Shanxi mature vinegar Daqu - barley and peas. After crushing, mix them according to the ratio of barley, peas and tartary buckwheat in a ratio of 5:3:2. .

[0056] b. Preparation of buckwheat red yeast rice

[0057] Mix shelled tartary buckwheat and millet in a ratio of 3:7, wash and soak for 40 minutes to drain the water, cook for 40 minutes under normal pressure, then cool down to 35°C in a sterile environment, and adjust the pH to 4.0 with lactic acid. Add 3% low-concentration ethanol (volume concentration is 5%). Mix and stir the functional Monascus strains and clinker evenly, the inoculum amount is 10% of the clinker weight, ferment and cultivate at 35°C for 10 days, and dry to obtain tartary buckwheat red yeast rice.

[0058] c. Prepa...

Embodiment 2

[0081] A brewing method of tartary buckwheat and red yeast rice vinegar, comprising the steps of:

[0082] 1. Koji making

[0083] a. Preparation of Tartary Buckwheat Daqu

[0084] Add tartary buckwheat to the original raw materials of Shanxi mature vinegar Daqu - barley and peas. After crushing, mix them according to the ratio of 4:3:3 of barley, peas and tartary buckwheat. .

[0085] B, the preparation of tartary buckwheat red yeast rice

[0086] Mix shelled tartary buckwheat and millet in a ratio of 4:6, wash and soak for 50 minutes to drain the water, cook for 30 minutes under normal pressure, then cool down to 30°C in a sterile environment, and adjust the pH to 3.5 with lactic acid. Add 4% low-concentration ethanol (volume concentration is 5%). Mix and stir the functional Monascus strains and clinker evenly, the inoculum amount is 5% of the weight of the clinker, ferment and cultivate at 32°C for 15 days, and then dry to obtain tartary buckwheat red yeast rice.

[00...

Embodiment 3

[0110] A brewing method of tartary buckwheat and red yeast rice vinegar, comprising the steps of:

[0111] 1. Koji making

[0112] a. Preparation of Tartary Buckwheat Daqu

[0113] Add tartary buckwheat to the original raw materials of Shanxi mature vinegar Daqu - barley and peas. After crushing, mix them according to the ratio of 5:2:3 of barley, peas and tartary buckwheat. .

[0114] B, the preparation of tartary buckwheat red yeast rice

[0115] Mix shelled tartary buckwheat and millet in a ratio of 1:2, wash and soak for 30 minutes to drain the water, cook for 50 minutes under normal pressure, then cool down to 35°C in a sterile environment, and adjust the pH to 4.5 with lactic acid. Add 5% low-concentration ethanol (volume concentration is 5%). Mix and stir the functional Monascus strains and clinker evenly, the inoculum amount is 15% of the clinker weight, ferment and cultivate at 33°C for 7 days, and then dry to obtain tartary buckwheat red yeast rice.

[0116] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com