Super-hydrophobic spraying transparent solution as well as preparation method and application thereof

A transparent solution and super-hydrophobic technology, applied in the field of materials, can solve the problems of losing super-hydrophobic properties, cumbersome preparation methods, and high equipment requirements, and achieve excellent super-hydrophobicity, mature technology, and convenient spraying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

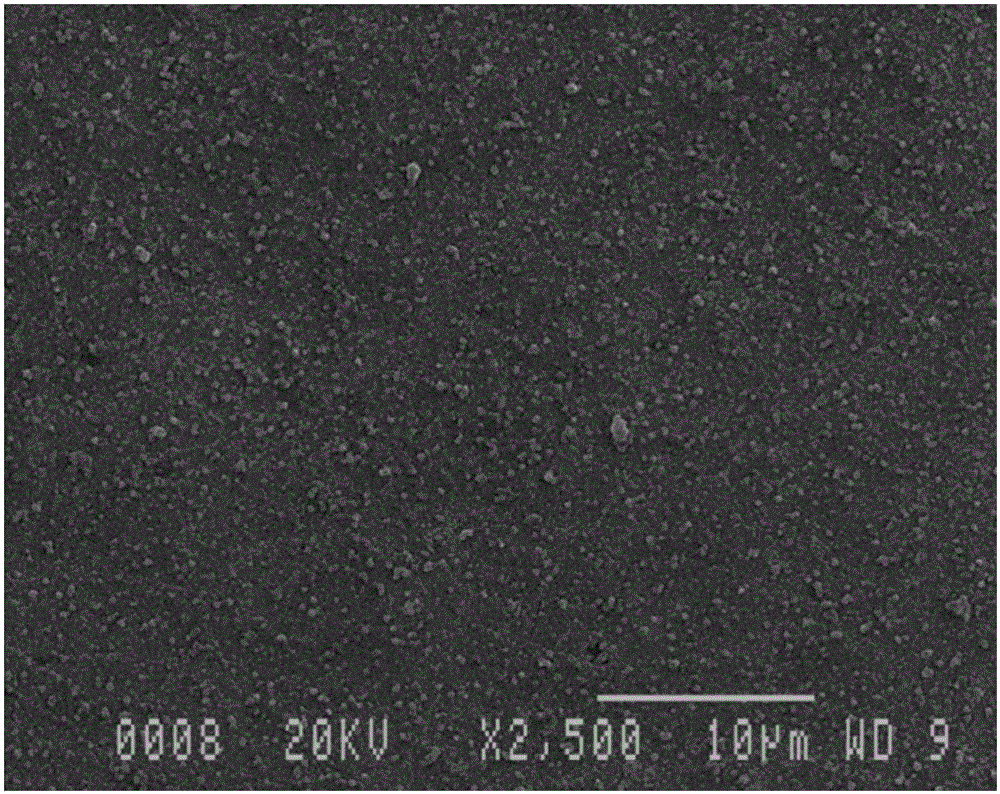

[0045] (1) Weigh 20 g of nano-SiO 2 , 30 g of silicone resin and 100 g of absolute ethanol were placed in a 250 mL beaker, stirred with a magnetic stirrer at 300 rpm for 30 min, and then ultrasonicated with an ultrasonic disperser with a power of 1000 W for 10 min to obtain a uniformly dispersed solution;

[0046] (2) Add 0.25 g of methyltriethoxysilane, 0.1 g of ascorbic acid, 0.15 g of sodium lauryl sulfate, 0.1 g of cobalt isooctanoate and 0.15 g of dodecyl to the dispersion prepared in step (1). Alcohol ester, and then use an ultrasonic disperser with a power of 1000 W for 10 minutes to obtain a stable dispersion, that is, to obtain the superhydrophobic spray transparent solution.

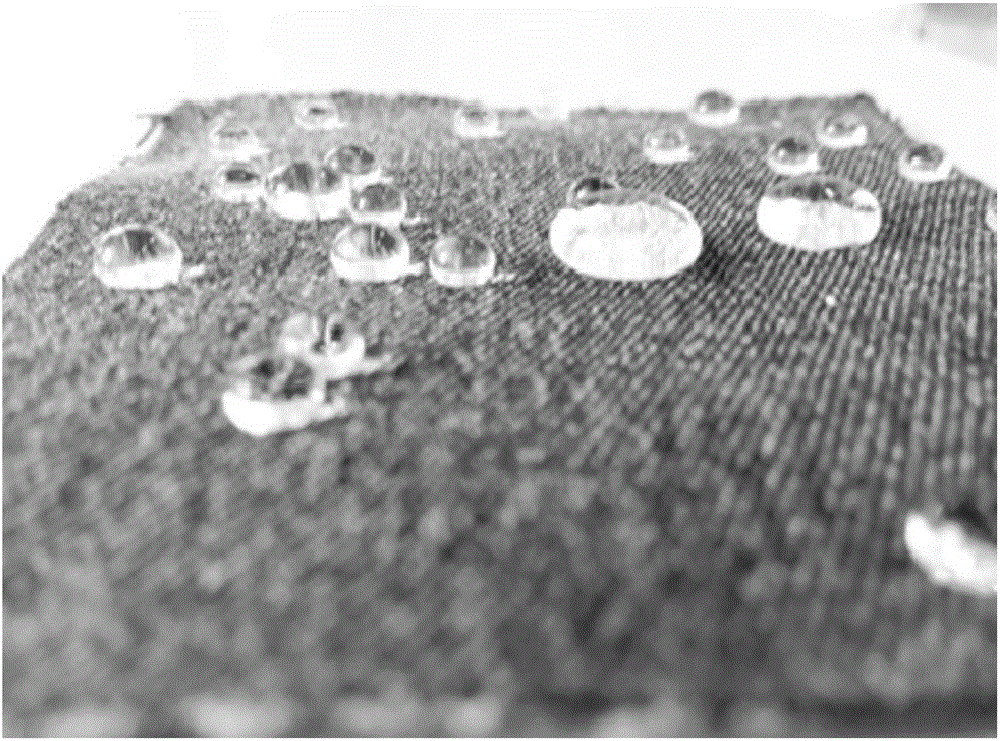

[0047] (3) Cut out a textile cloth of a certain size, and spray the dispersion liquid in step 1 evenly on the textile cloth. After the ethanol is completely volatilized, the surface of the textile cloth obtains a super-hydrophobic coating.

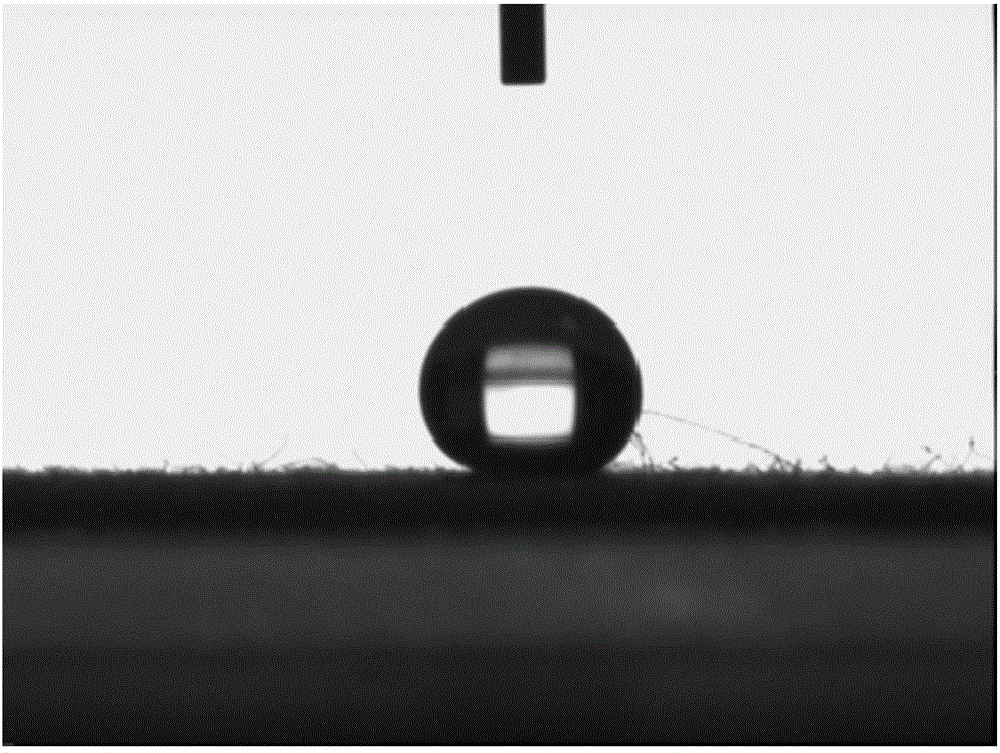

[0048] (4) The contact angle of the woven fabric obtai...

Embodiment 2

[0050] (1) Weigh 0.01 g nano-TiO respectively 2 and 100 g of isopropanol in a 250 mL beaker, stirred with a magnetic stirrer at 200 rpm for 1 min, and then ultrasonicated with an ultrasonic disperser with a power of 100 for 1 min to obtain a uniformly dispersed solution;

[0051] (2) Add 0.005 g of γ-chloropropyltriethoxysilane, 0.006 g of 2,6-di-tert-butyl-4-methylphenol, 0.004 g of hexamethene to the dispersion prepared in step (1) Sodium phosphate, 0.003 g of manganese isooctanoate and 0.007 g of dimethyldiallyl ammonium chloride, followed by ultrasonication with an ultrasonic disperser with a power of 100 for 1 min to obtain a stable dispersion, that is, to obtain the superhydrophobic spray transparent solution.

[0052] (3) Cut out a certain size of textile cloth, spray the dispersion in step 1 evenly on the textile cloth, and after the isopropanol is completely volatilized, the surface of the textile cloth obtains a super-hydrophobic coating.

[0053] (4) The contact an...

Embodiment 3

[0055] (1) Weigh 5 g of nano-Al respectively 2 o 3 , 15 g of fluorocarbons and 100 g of acetone were placed in a 250 mL beaker, stirred with a 500 rpm magnetic stirrer for 15 min, and then ultrasonicated with a 500 W ultrasonic disperser for 5 min to obtain a uniformly dispersed solution;

[0056] (2) Add 5 g of polydimethylsiloxane, 6 g of tert-butylhydroquinone, 4 g of fatty acid polyethylene glycol ester, 3 g of p-toluenesulfonate to the dispersion prepared in step (1). Acid amine and 7 g of acrylic resin, followed by ultrasonic dispersing with a power of 500 W for 5 minutes to obtain a stable dispersion, that is, to obtain the superhydrophobic spray transparent solution.

[0057] (3) Cut out a denim fabric of a certain size, and spray the dispersion liquid in step 1 evenly on the denim fabric. After the acetone is completely volatilized, a superhydrophobic coating is obtained on the surface of the textile fabric.

[0058] (4) The contact angle of the woven fabric obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com