Precious-metal micro-nanometer structure and preparing method and application thereof

A micro-nano structure, precious metal technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult control of metal structure, complex template printing process, complicated and time-consuming, etc. Adjustable performance, good enhanced activity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

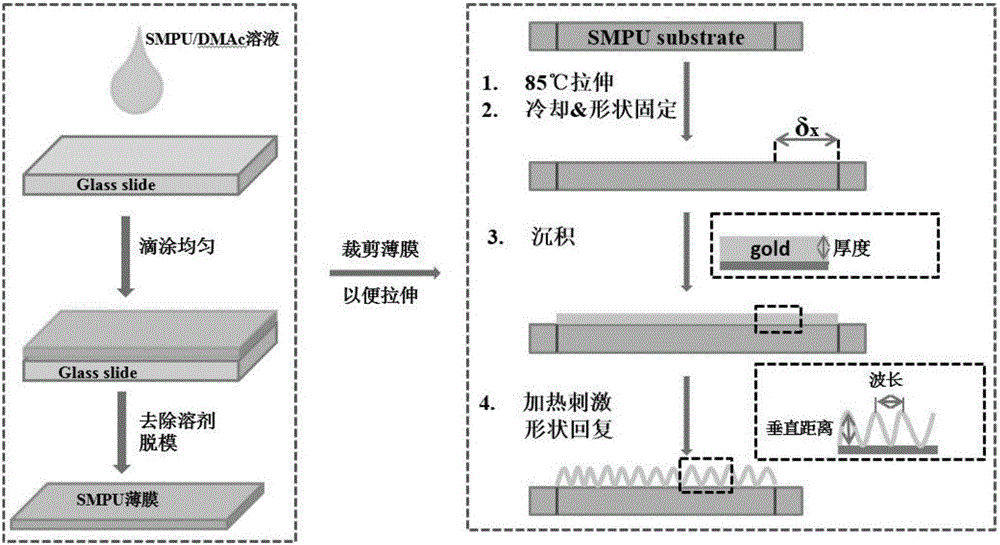

[0025] For the preparation method of gold micro-nanostructure, see figure 1 ,details as follows:

[0026] Preparation of shape-memory polymer film: Place a 2.5cm×7.6cm glass slide in anhydrous ethanol, ultrasonically clean it and dry it, and dissolve shape-memory polyurethane in N,N-dimethylacetamide to obtain a concentration of 150mg / mL solution, 2mL of the obtained solution is evenly coated on the cleaned glass slide to form a thin layer, put it in a vacuum oven at 90°C to dry, completely remove the solvent N,N-dimethylacetyl, and obtain a shape memory polymer For the film, the shape memory polymer film is cut according to 2.5cm×1cm, placed in anhydrous ethanol for ultrasonic cleaning, and then dried naturally to obtain a shape memory polymer film sample;

[0027] Preparation of gold micro-nanostructures: fix the shape memory polymer film sample on the fixture of the tensile machine, and adjust the ambient temperature to 85°C (at this temperature, the shape memory polyureth...

Embodiment 2

[0031] The preparation method of the gold micro-nano structure is as follows:

[0032] The shape-memory polymer film sample prepared in Example 1 was fixed on the clamp of the tensile machine, and the ambient temperature was adjusted to 85°C (at this temperature, the shape-memory polyurethane was in a high elastic state), and the shape-memory polymer film was stretched along the shape-memory polymer film with the tensile machine. The length direction of the sample is elongated by 10% (stretching rate is 5mm / min), which is 1.1 times of the original length, and the temperature is naturally cooled to room temperature. With the help of the shape memory effect of the shape memory polymer material, the shape memory polymer film sample remains stretched. The state after stretching remains unchanged;

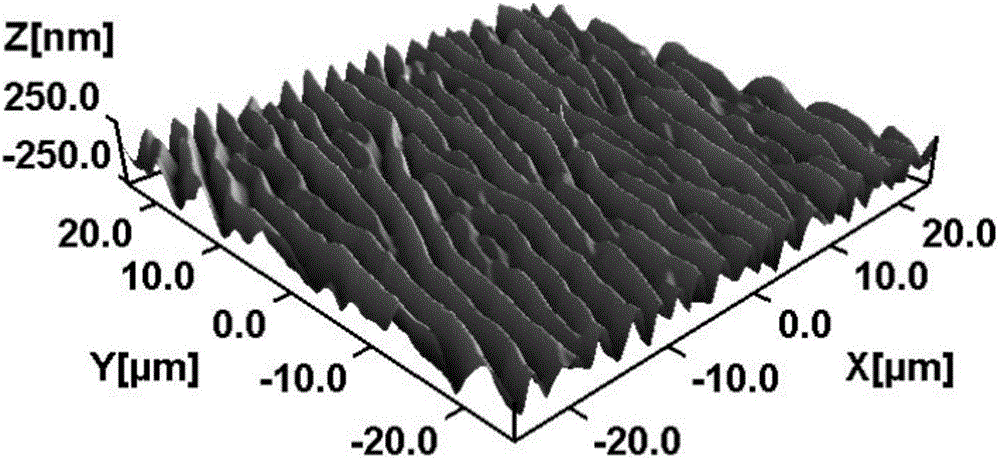

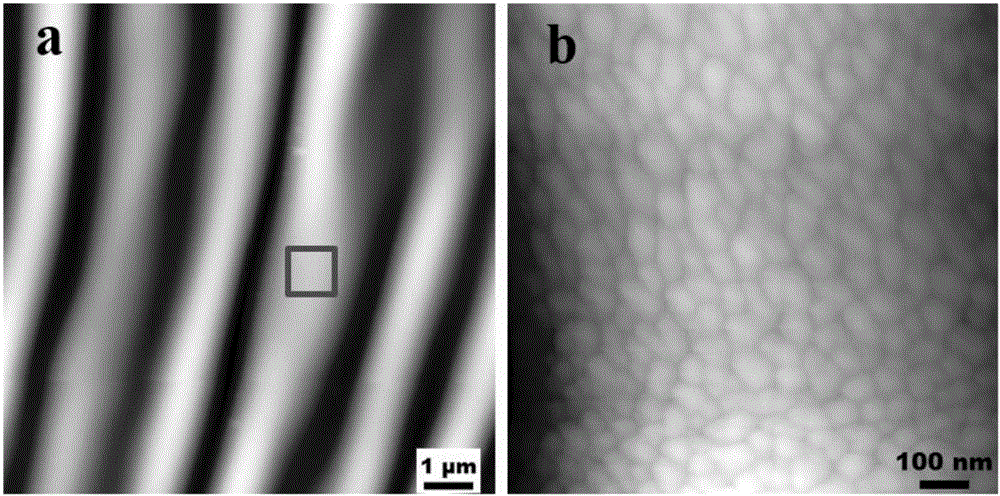

[0033] Put the stretched shape-memory polymer film sample into the vacuum ion sputtering apparatus, and the vacuum degree is 5×10-4 Under the vacuum state of Pa, according to the deposi...

Embodiment 3

[0035] The preparation method of gold micro-nanostructure is as follows:

[0036] The shape-memory polymer film sample prepared in Example 1 was fixed on the clamp of the tensile machine, and the ambient temperature was adjusted to 85°C (at this temperature, the shape-memory polyurethane was in a high elastic state), and the shape-memory polymer film was stretched along the shape-memory polymer film with the tensile machine. The length direction of the sample is stretched by 20% (the stretching rate is 5mm / min), which is 1.2 times of the original length, and the temperature is naturally cooled to room temperature. With the help of the shape memory effect of the shape memory polymer material, the shape memory polymer film sample remains stretched. The state after stretching remains unchanged;

[0037] Put the stretched shape-memory polymer film sample into the vacuum ion sputtering apparatus, and the vacuum degree is 5×10 -4 Under the vacuum state of Pa, according to the depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com