Cold cathode structure capable of allowing space electric propulsion to be started quickly

A quick-start, cold-cathode technology, applied in the direction of discharge tube cold cathode, discharge tube main electrode, etc., can solve problems such as low reliability, difficult process, complex system, etc., to increase system reliability, improve response performance, simplify The effect of system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

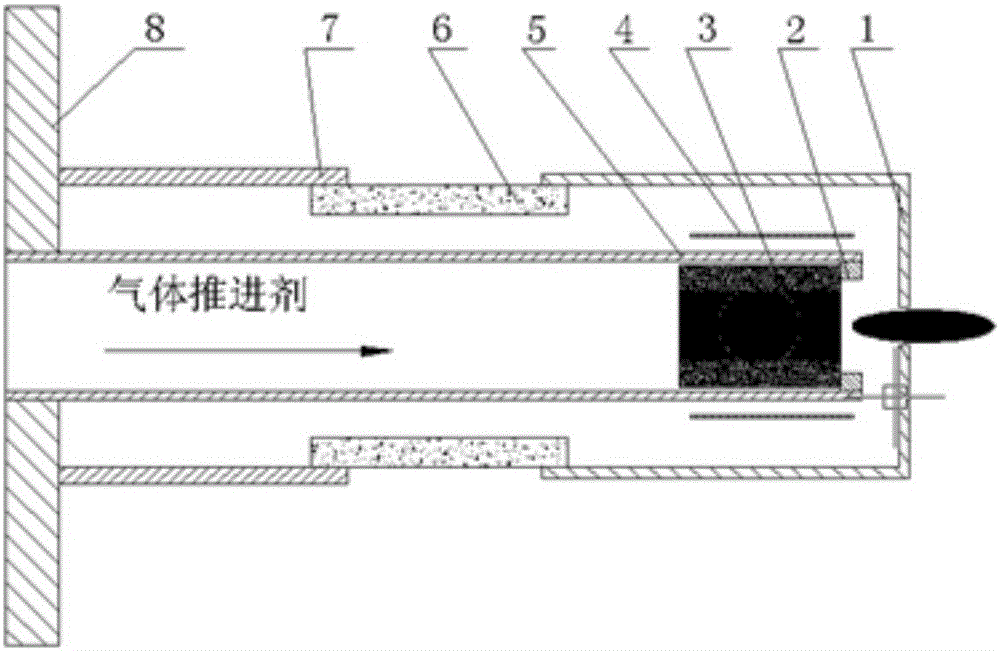

Image

Examples

Embodiment 1

[0023] Emitter material selection 411 type barium tungsten emitter (BaO:Al 2 o 3 :CaO molar ratio 4:1:1), molybdenum is used for ignition electrode, cathode top and cathode tube, titanium is used for heat shield, and 95% Al is used for insulator 2 o 3 Ceramic, other materials choose stainless steel.

[0024] In a vacuum of 5 x 10 -4 In the Pa environment, the flow rate of the quick-start cold cathode assembly is 3-5 sccm (standard cubic centimeter per minute) xenon working fluid, the internal gas pressure reaches about 3800Pa, and a high voltage of 300-500V is applied between the ignition electrode and the cathode top. The cathode discharges within 20ms and can stably emit an electron current of 1.5-2.5A.

Embodiment 2

[0026] The emitter material is polycrystalline lanthanum hexaboride, the ignition electrode, cathode top, and cathode tube are made of molybdenum, the heat shield is made of titanium, and the insulator is made of 95% Al 2 o 3 Ceramic, other materials choose stainless steel.

[0027] In a vacuum of 5 x 10 -4 In the Pa environment, the flow rate of the cold cathode is 5-10sccm (standard cubic centimeters per minute) xenon working fluid, the internal gas pressure reaches about 4500Pa, and a high voltage of 600-1000V is applied between the ignition electrode and the top of the cathode. Internal discharge can stably emit electron current of 2.5-4.5A.

Embodiment 3

[0029] The emitter material is selectively doped scandate type 612 barium tungsten emitter (BaO:Al 2 o 3 :CaO molar ratio 6:1:2), molybdenum is used for ignition electrode, cathode top and cathode tube, molybdenum cylinder is used for heat shield, and 95% Al is used for insulator 2 o 3 Ceramic, other materials choose stainless steel.

[0030] In a vacuum of 5 x 10 -4 In the Pa environment, the flow rate of the cold cathode is 3-5sccm (standard cubic centimeters per minute) xenon working fluid, the internal gas pressure reaches about 3000Pa, and a high voltage of 300-500V is applied between the ignition electrode and the top of the cathode. Internal discharge can stably emit 1.5-4.5A electron current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com