Smart Solid Low Voltage DC Electrical Junction Box

An electrical junction box, low-voltage direct current technology, applied in the direction of electrical components, conductive connections, connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

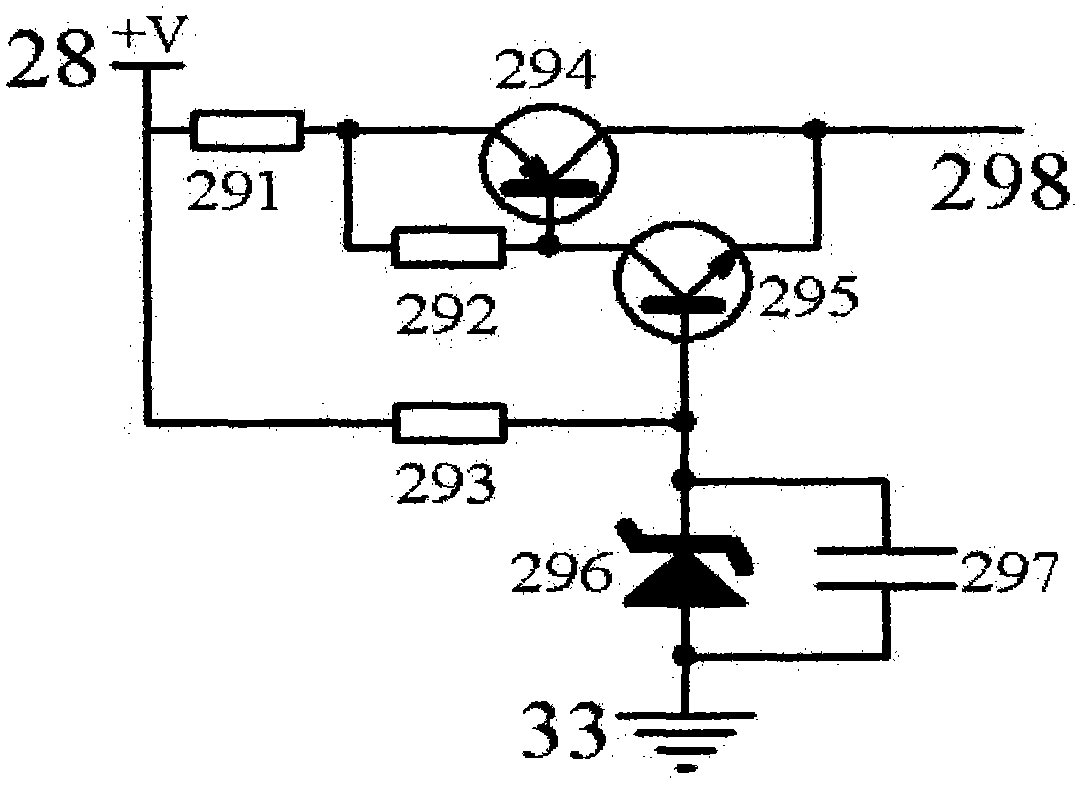

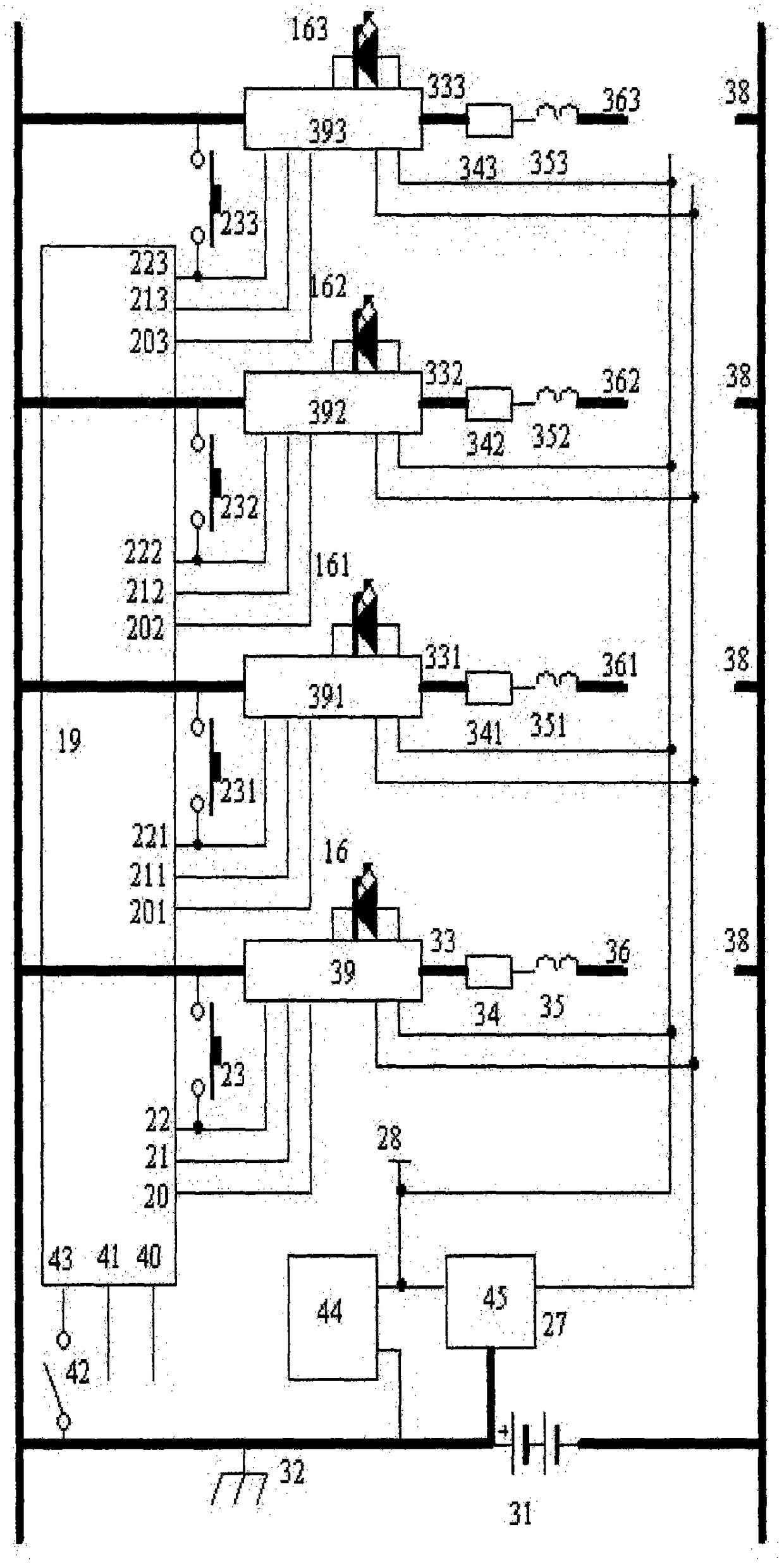

[0048] The specific circuit implementation mode 1 is a positive voltage control output type solid junction box, figure 1 is the circuit diagram of one of the branches; figure 2 It is the internal circuit diagram of the power supply regulator 29 of one of the branch MOS transistors 1 driving the IC26 in the positive voltage control output type electrical junction box; image 3 It is a circuit wiring schematic diagram of using one CPU 19 to control the positive voltage control output of 4 branches; the CPU 19 adopts Hongjing STC15F2K series or other single-chip microcomputers that meet the functional requirements.

[0049] In this embodiment, the main switching power element of each power supply branch adopts N-channel MOS transistor 1, and each branch N-channel MOS transistor can be one, or multiple can be connected in parallel as a power supply output branch. The drains of the main switch N-channel MOS transistors 1 of all solid junction boxes are connected to the positive e...

specific Embodiment approach 2

[0063] The specific circuit implementation mode 2 is a negative voltage control output type solid junction box, Image 6 is the circuit diagram of one of the branches, Figure 4 It is a circuit wiring schematic diagram of using 1 CPU 19 to control 4 branch negative voltage control outputs.

[0064] Only the differences from the circuit hardware embodiment 1 will be described below

[0065] Image 6 Among them, the sampling resistance of the output current is still replaced by the channel resistance when the main switch N-channel MOS transistor of this branch is turned on, and the current sampling signal of the current sampling point 33 is sent to the non-inverting input terminal of the amplifier 4 through the current limiting resistance 37, and the current The inverting input terminal of the sampling signal amplifier 4 is connected in series with the compensation thermistor 3 through the resistor 2 and then grounded; the common ground terminal of all amplification, compariso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com