Cornea scaffold material and preparation method thereof and 3D printing method of cornea scaffold

A technology of scaffold material and cornea, which is applied in the field of implant materials and organs in medical devices, can solve the problems that patients cannot get it, donor cornea cannot regain vision, and the height of donated cornea is scarce, so as to achieve good transparency and improve degradation speed. Fast, the effect of improving mechanical strength and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

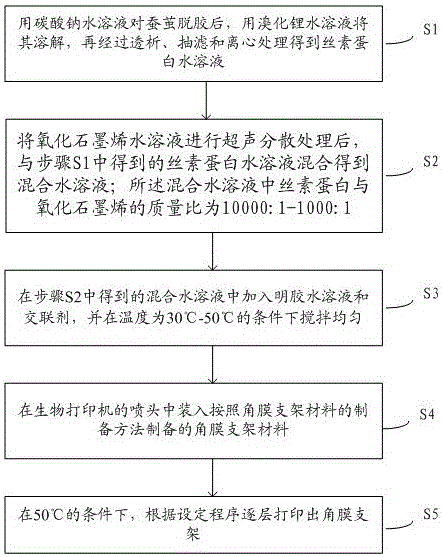

[0022] The preparation method of this corneal stent material, such as figure 1 shown, including the following steps:

[0023] Step S1: degumming silkworm cocoons with sodium carbonate aqueous solution, dissolving them with lithium bromide aqueous solution, and then obtaining silk fibroin aqueous solution through dialysis, suction filtration and centrifugation.

[0024] Here, the mass percentage of the calcium carbonate aqueous solution is 0.5%-1%, and the molar concentration of the lithium bromide aqueous solution is 9.5±0.3mol / L.

[0025] The dialysis treatment is specifically as follows: the lithium bromide aqueous solution dissolved with degummed silkworm cocoons is dialyzed in deionized water for 72 hours with a dialysis bag with a molecular weight cut-off of 3500; during this period, the water is changed every 2 hours.

[0026] The silk fibroin aqueous solution obtained after dialysis, suction filtration and centrifugation needs to be concentrated at 10°C-78°C for 3-200 ...

Embodiment 2

[0048] Put 50g silk into 0.5% Na 2 CO 3 Degumming was carried out in the solution and dried. During degumming, the silk was boiled at 100°C for 1 hour to remove sericin on the outside of the silk, rinsed with deionized water, and the above operation was repeated 3 times, and then the silk was dried at 60°C.

[0049] Weigh 15 g of the degummed silk after the above treatment and put it into 100 mL of LiBr solution with a concentration of 9.3 mol / L for dissolving treatment, and dissolve at 60° C. for 4 hours during the dissolving treatment. Then above-mentioned LiBr solution that is dissolved with silk is carried out dialysis treatment, during dialysis, with the dialysis bag of molecular weight cut-off 3500, soak in deionized water and dialyze for 3 days, change water once every two hours during the period, to remove LiBr in the solution, thereby obtain pure Silk fibroin solution, its concentration is 6%.

[0050] Concentrate the silk fibroin solution above at 60°C for 120 hour...

Embodiment 3

[0054] Put 50g silk into 0.5% Na 2 CO 3 Degumming was carried out in the solution and dried. During degumming, the silk was boiled at 100°C for 1 hour to remove sericin on the outside of the silk, rinsed with deionized water, and the above operation was repeated 3 times, and then the silk was dried at 60°C.

[0055] Weigh 15 g of the degummed silk after the above treatment and put it into 100 mL of LiBr solution with a concentration of 9.3 mol / L for dissolution treatment, and dissolve at 60° C. for 4 hours during the dissolution treatment. Then above-mentioned LiBr solution that is dissolved with silk is carried out dialysis treatment, during dialysis, soak the dialysis bag of molecular weight cut-off 3500 in deionized water and dialyze for 3 days, change water once every two hours during the dialysis, to remove LiBr in the solution, thereby obtain pure Silk fibroin solution, its concentration is 6%.

[0056] The graphene oxide aqueous solution with a concentration of 2 mg / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com