Method for removing perchlorate in water

A perchlorate and water removal technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as low treatment efficiency, low selectivity, and difficult regeneration of perchlorate. Achieve the effects of short reaction time, high processing efficiency and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (comparative example)

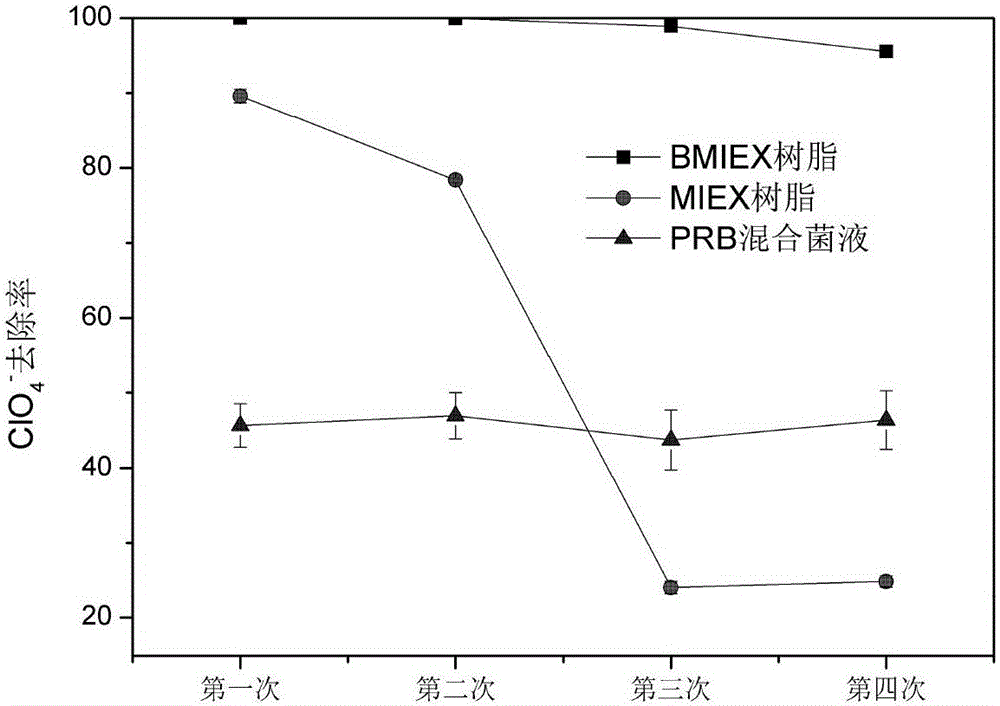

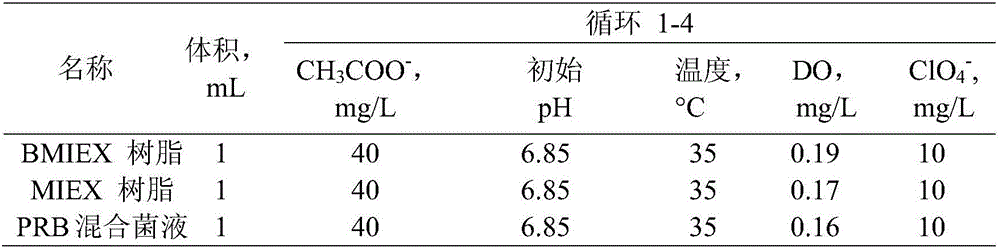

[0032] Take 1 mL each of biomagnetic resin, magnetic resin and PRB mixed bacterial pages and place them in 250 mL serum bottles, and add 150 mL of the culture solution described in the above step (1) and 10 mg / L ClO to each serum bottle. 4 - and 40mg / L of CH3COO - , the reaction conditions are shown in Table 1. The rotating speed on the shaker is 120rpm, the treatment period is 12h, and the residual content of perchlorate in the water is detected. Then all the resins do not undergo any regeneration, pour the upper layer culture solution, and add fresh culture solution, which is the same as the first cycle, so that 4 cycles are performed to compare the treatment effects of the three, and the results are as follows figure 1 shown. Depend on figure 1 It can be seen that after 4 consecutive uses, the BMIEX resin still maintains a high perchlorate removal rate, while the adsorption capacity of the magnetic resin is quickly exhausted ...

Embodiment 2

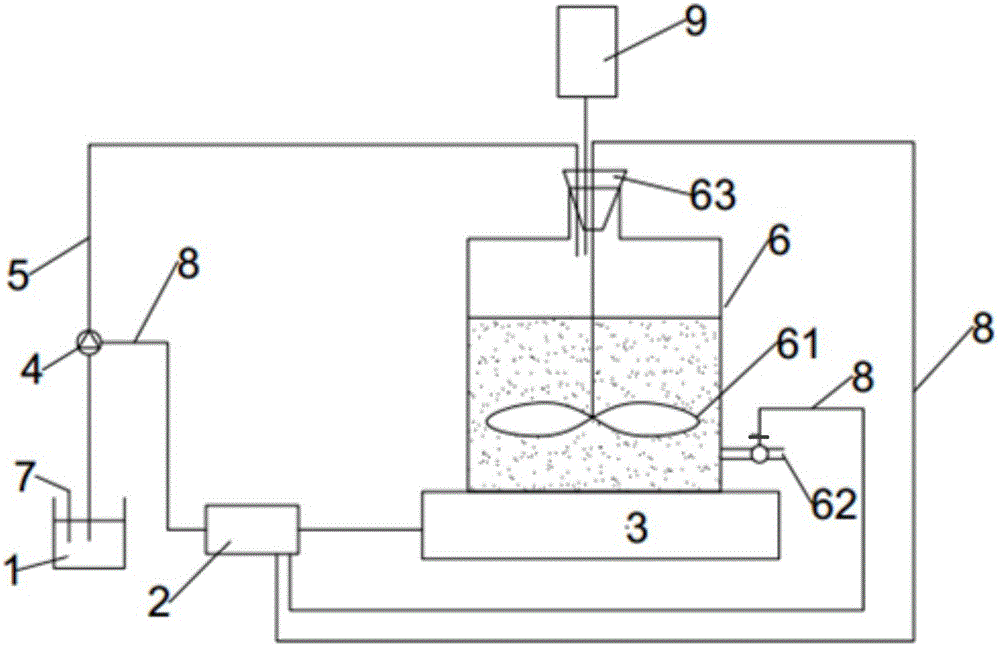

[0036] established as figure 2 In the shown reactor, 1 is a perchlorate-contaminated raw water pool, which is used to hold perchlorate-contaminated water to be treated; 2 is an automatic controller, which is the overall director of the operation of the whole device. Mainly control the timing opening and closing of peristaltic pump 4, stirring paddle 61, electromagnet 3 and water outlet valve 62; 5 is the water inlet pipe; 6 is the cylindrical mixing reactor, which is the reaction place, and there is stirring paddle 61 inside to ensure sufficient mixing; 7 is the place where the carbon source is added, when the carbon source in the water is insufficient, it is used to supplement the carbon source; 8 is the control circuit, connected with the automatic controller 2; 9 is the air bag, which is used to collect the gas produced in the reaction process and keep The balance of the air pressure inside and outside the reactor; 63 is a sealing plug to ensure the anaerobic environment i...

Embodiment 3

[0038] established as figure 2 In the shown reactor, the artificial water distribution (that is, the above-mentioned medium) containing 25mg / L perchlorate and 100mg / L sodium acetate is placed in pool 1, and 100mL of biomagnetic resin obtained by the above method is placed in In the mixing reactor 6, the volume of the reactor is 10L, and the processing process is realized by the automatic controller 2 through the control circuit 8. The automatic control process is as follows: the peristaltic pump 4 is turned on, and the water inlet flow rate is 2L / min. After 4 minutes, the peristaltic pump 4 close, and the stirring paddle 61 rotates at the same time, the rotating speed is 70rpm, the reaction starts, and the treatment is completed after 7h. The water outlet valve 62 is opened, and all the treated water is discharged after 2 minutes. At this time, the water outlet valve 62 is closed, the electromagnet is turned off, and the peristaltic pump 4 is opened simultaneously to start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com