Clean preparation method for plant polypeptide/protein

A plant polypeptide and protein technology, which is applied in the field of clean preparation of plant polypeptide/protein, can solve the problems of uncontrollable molecular weight ratio, different effects, large average molecular weight, etc., and achieve controllable molecular weight range, low viscosity and high solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

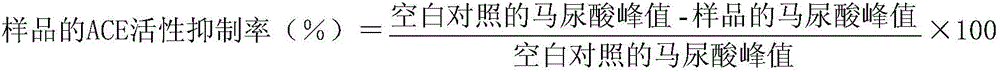

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of plant polypeptide using soybean meal as raw material

[0042] Proceed as follows:

[0043] (1) Raw material pretreatment: firstly, the soybean meal is tested to ensure that there is no spoilage or mold. Then, ultrasonic pretreatment is performed for 360 seconds, then crushed, passed through a 60-mesh sieve, and set aside.

[0044] (2) Slurry adjustment: Under stirring conditions, slowly add the above-mentioned crushed and sieved raw materials to a sodium hydroxide solution with a pH of 9.5, with a solid-liquid ratio of 1:10 (mass ratio).

[0045] (3) Extraction and separation: Under agitation, the temperature is raised to 55±2°C and reacted for 2.5 hours to fully extract; after the reaction, the solid-liquid separation is performed to obtain the supernatant for use.

[0046] (4) Purification: adjust the pH of the above supernatant to 5, let it stand to fully flocculate the protein, and then separate the solid-liquid to obtain crude protein, wash twice wit...

Embodiment 2

[0052] Example 2 Preparation of plant polypeptide with peanut meal as raw material

[0053] Proceed as follows:

[0054] (1) Raw material pretreatment: First, the peanut meal is tested to ensure that there is no spoilage or mold. Then, ultrasonic pretreatment is performed for 600 seconds, then crushed, passed through an 80-mesh sieve, and set aside.

[0055] (2) Slurry adjustment: Under stirring conditions, slowly add the above-mentioned crushed and sieved raw materials to an alkali solution sodium hydroxide solution with a pH of 9.5, and the solid-liquid ratio is 1:12 (mass ratio).

[0056] (3) Extraction and separation: Under agitation, the temperature is raised to 55±2°C and reacted for 3 hours to fully extract; after the reaction, solid-liquid separation is performed to obtain the supernatant for use.

[0057] (4) Purification: adjust the pH of the above supernatant to 4.5, leave it to stand to fully flocculate the protein, and then separate the solid-liquid to obtain crude protein,...

Embodiment 3

[0063] Example 3 Preparation of Plant Polypeptide with Corn Yellow Powder as Raw Material

[0064] Proceed as follows:

[0065] (1) Raw material pretreatment: Firstly, the corn yellow powder is tested to ensure that there is no spoilage or mold. Then, ultrasonic pretreatment is performed for 380 seconds, then crushed, passed through a 100-mesh sieve, and set aside.

[0066] (2) Slurry adjustment: Under stirring conditions, slowly add the above-mentioned crushed and sieved raw materials to a sodium hydroxide solution with a pH of 9.5, and a solid-to-liquid ratio of 1:8 (mass ratio).

[0067] (3) Extraction and separation: Under agitation, the temperature is raised to 55±2°C and reacted for 3 hours to fully extract; after the reaction, solid-liquid separation is performed to obtain the supernatant for use.

[0068] (4) Purification: adjust the pH of the above supernatant to 4.5, leave it to stand to fully flocculate the protein, and then separate the solid-liquid to obtain crude protein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com