Dry distillation device with lower furnace body capable of moving up and down and dry distillation method of dry distillation device

A furnace body and dry distillation technology, used in furnace control devices, special forms of dry distillation, furnaces, etc., can solve problems such as small amount of material, inability to examine the heating method and thickness of the material layer, and inability to examine the impact of dry distillation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

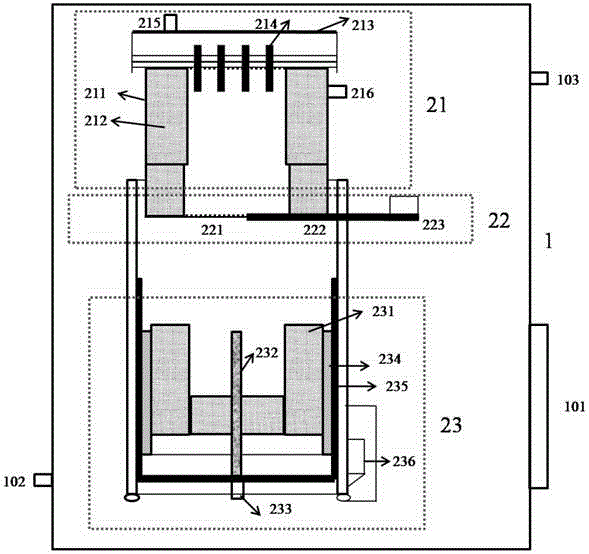

[0060] Such as figure 1 Shown is a structural schematic diagram of a retort device with a lower furnace body that can move up and down according to an embodiment of the present invention. The figure includes a nitrogen cooling box 1 and a high-temperature retort furnace body 2 .

[0061] Such as figure 1 , The nitrogen cooling box 1 is provided with a box door 101 and a nitrogen inlet 102 and a nitrogen outlet 103 . The function of the nitrogen cooling box 1 is to replace the atmosphere in the box with a nitrogen atmosphere, or other inert gas atmospheres. The inert gas protection is maintained during the feeding and discharging process to prevent the dry distillation product from being burned by contacting oxygen at high temperature.

[0062] from figure 1 It can be seen that the high temperature carbonization furnace body 2 includes an upper furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com