Zinc oxide pressure sensitive resistor

A piezoresistor and zinc oxide technology, which is applied to piezoresistor cores, piezoresistors, resistors, etc., can solve the problems of silver consumption, high production cost, and large ohmic contact resistance, so as to improve the flow capacity , reduce the effect of Joule heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

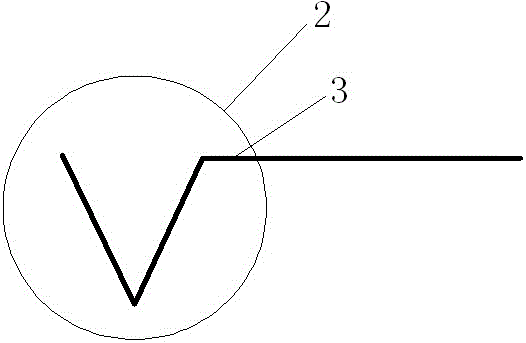

[0034] Such as image 3 Shown, according to this preparation method, comprise the steps:

[0035] a) Provide a zinc oxide ceramic substrate.

[0036] The zinc oxide ceramic substrate 1 can be a commercially available zinc oxide ceramic substrate generally used to prepare zinc oxide varistors, or a zinc oxide ceramic substrate prepared by the method in the prior art.

[0037] b) setting an electrode layer on the surface of the zinc oxide ceramic substrate.

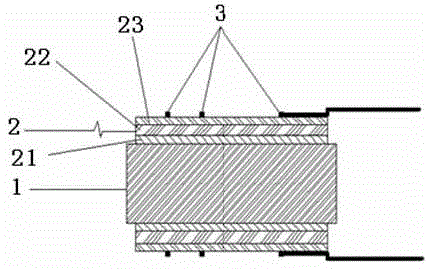

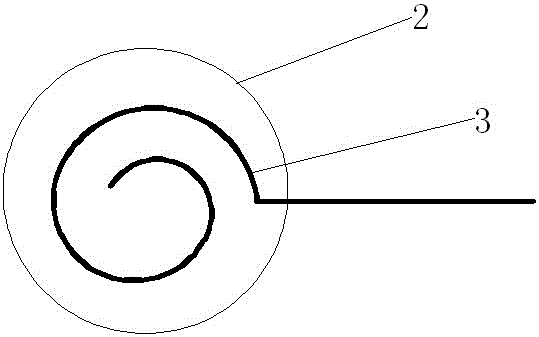

[0038] When setting the electrode layer 2, it can be as figure 1 As shown, the transition layer 21 , the barrier layer 22 , and the welding layer 23 are sputtered sequentially on both sides of the zinc oxide ceramic substrate 1 ; only the transition layer 21 and the welding layer 23 can also be sputtered.

[0039] Regarding the specific materials and film thicknesses of the transition layer 21 , the barrier layer 22 , and the soldering layer 23 , refer to the above description for the resistor, and details will not be re...

Embodiment 1

[0058] In this embodiment, a three-layer structure electrode layer is prepared by sputtering on the surface of a zinc oxide varistor ceramic chip whose diameter is Φ10mm and thickness is 2mm and whose type is 10471K. Wherein, the bottom transition layer is made of chrome, the intermediate barrier layer is made of nickel-copper alloy, and the surface welding layer is made of silver.

[0059] In order to remove impurities on the surface of the zinc oxide ceramic substrate, put the zinc oxide ceramic substrate into a ball mill for rolling washing for 30 minutes, then ultrasonically clean it in tap water and deionized water for 20 minutes respectively, and dry it in an oven at 120°C. Let dry for 20 minutes.

[0060] Put the cleaned and dried zinc oxide ceramic substrate into the special mask fixture, and then install the mask fixture on the workpiece holder; send the workpiece holder into the multi-target sputtering equipment, and vacuumize the equipment cavity , so that the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com