Ammonium sulfate paste tobacco bud inhibitor and application method thereof

A technology of ammonium sulfate slurry and sprout inhibitor, applied in gardening methods, botany equipment and methods, applications, etc., can solve problems such as potassium nutrient consumption, chemical drug residues, and easily infectious pathogens as viruses, so as to reduce nutrition Consumption, removal of tobacco leaf pesticide residues, human and animal safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

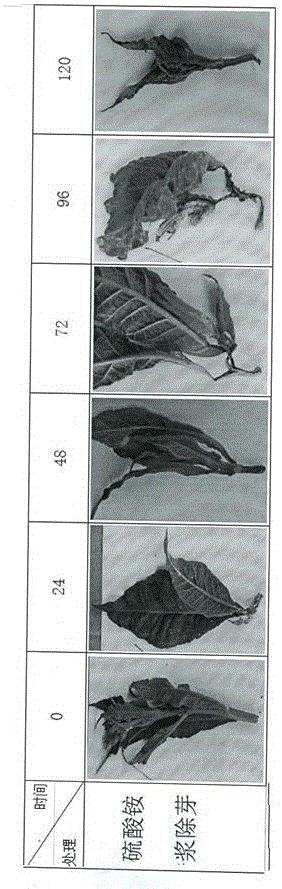

Image

Examples

Embodiment

[0021] Tobacco bud suppression work was carried out in a tobacco cultivation field. First, after mixing flour and water in a container according to the mass ratio of 1:8, pour it into a pot and heat it to 100°C through a 500W induction cooker, boil for 2 minutes to obtain a paste, which is used as a carrier; take ammonium sulfate powder and The paste is stirred evenly according to the mass ratio of 2:1, and the ammonium sulfate pulp tobacco sprout suppressant is prepared, which is set aside;

[0022] Then carry out suppressing bud preparation, select the tobacco strain that has tobacco bud to take place as suppressing bud as processing object, carry out listing mark to processing tobacco bud, prepare suppressing bud;

[0023] On sunny days, use a brush to soak the sprout inhibitor (NH4)2SO4 slurry on the tobacco buds of the listed tobacco plants to directly smear the tobacco buds; in the process, pay attention to the (NH4)2SO4 slurry as far as possible without contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com