Preparation method of medicago sativa solid beverage

A technology of alfalfa and solid beverage, which is applied in food forming, food processing, food science, etc., can solve the problems of loss of saponins, flavonoids and protein components, etc., and achieve easy absorption by the human body, reasonable nutrient distribution ratio, yield and The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

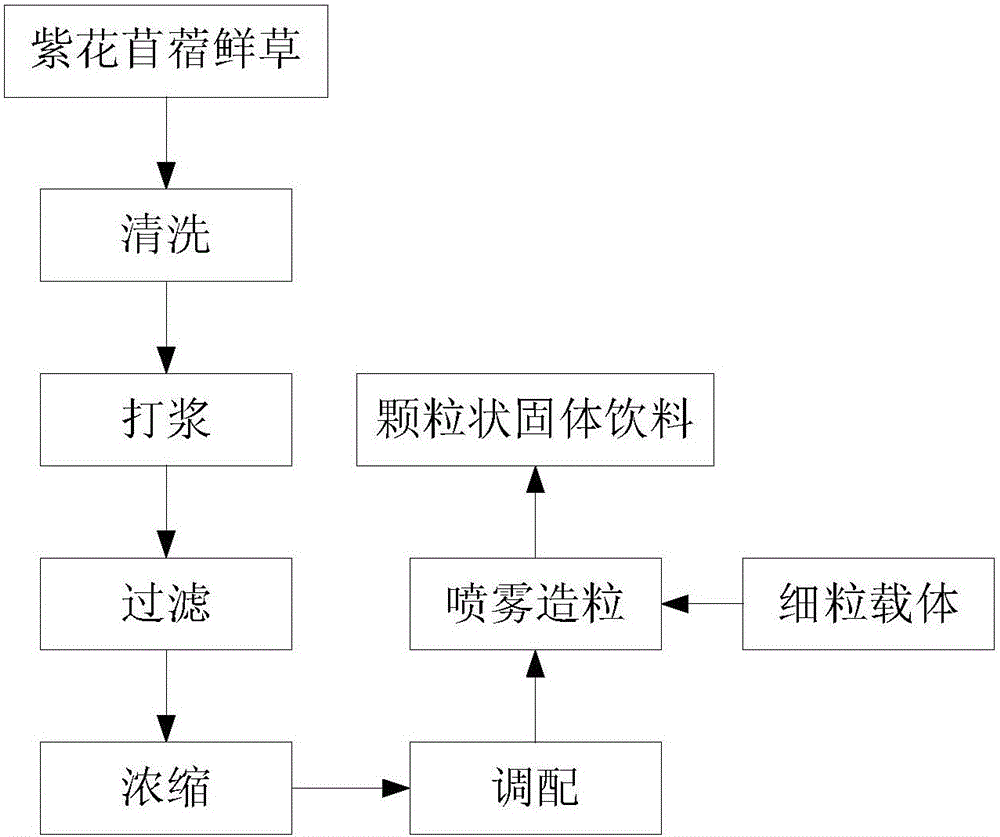

[0033] combine figure 1 Shown, illustrate the preparation method of the alfalfa solid drink of the embodiment of the present invention 1, comprises the following steps:

[0034] Step 1. After removing impurities and cleaning the fresh alfalfa grass, beating and filtering (for example, pressure filtration) in order to obtain a slurry; then concentrating the slurry to obtain a concentrated slurry; Control at 45°C-50°C.

[0035] Step 2: adding auxiliary materials to the concentrated slurry and mixing evenly to obtain a molding material liquid; the auxiliary materials include cyclodextrin; and the grassy smell of the concentrated slurry is embedded by using the cyclodextrin.

[0036] Step 3: Spray and granulate the molding liquid obtained in Step 2 to obtain a granulated alfalfa solid drink; wherein, during the spray granulation process, an edible fine particle carrier is added.

[0037] In the present invention, the spray granulation method is adopted, the fine-grained carrier ...

Embodiment 2

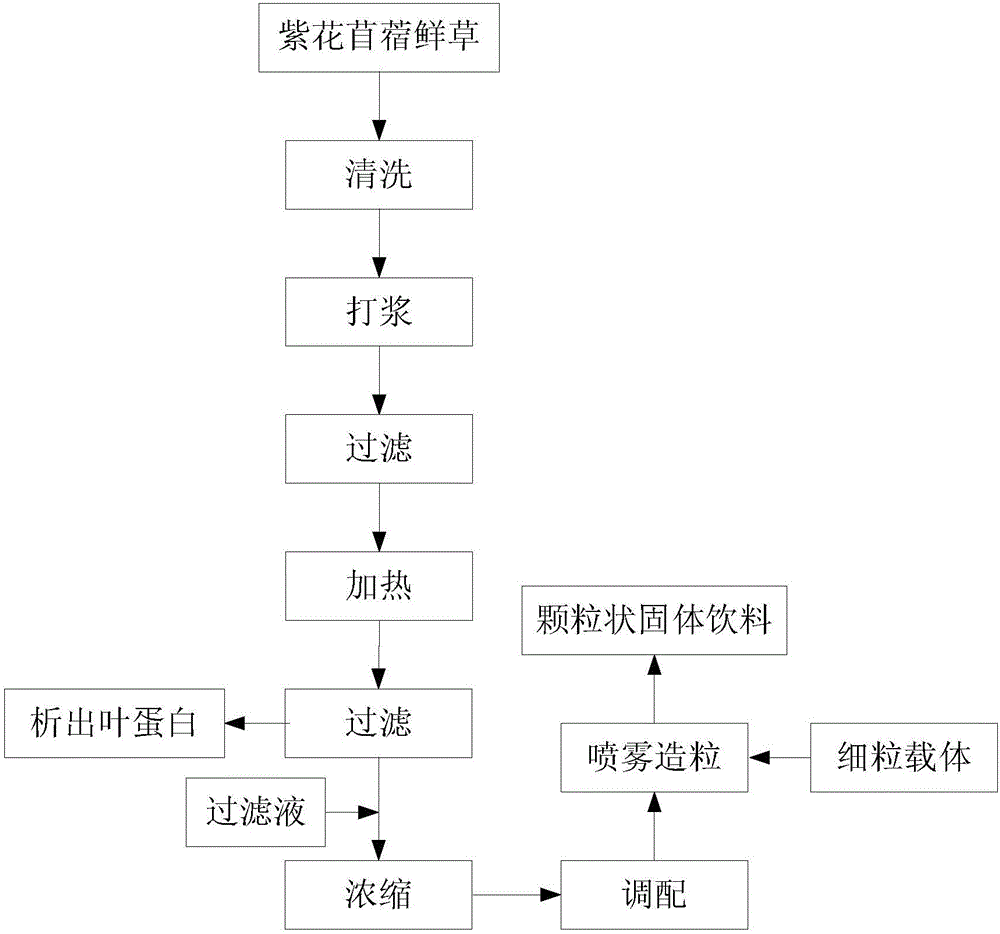

[0058] The preparation method of the alfalfa solid beverage of the embodiment of the present invention 2 comprises the following steps:

[0059] Step 1, after removing impurities and cleaning the fresh grass of alfalfa, beating and filtering (for example, pressure filtration) successively to obtain a slurry; then concentrating the slurry to obtain a concentrated slurry; controlling the density of the concentrated slurry to be 1.1-1.2g / cm 3 . Concentration treatment is carried out with a low-temperature decompression concentrator, and the temperature is controlled at 45°C-50°C.

[0060] Step 2: adding auxiliary materials to the concentrated slurry, blending and mixing to obtain a molding material liquid; the auxiliary materials include cyclodextrin; the mass ratio of cyclodextrin to concentrated slurry is controlled to be 1:36.

[0061] Step 3. Spray granulate the molding material liquid obtained in step 2 to obtain granular alfalfa solid beverage; wherein, in the process of...

Embodiment 3

[0065] The preparation method of the alfalfa solid beverage of the embodiment of the present invention 3 comprises the following steps:

[0066] Step 1, after cleaning the fresh alfalfa grass, beating and filtering (for example, pressure filtration) in order to obtain a slurry; then concentrating the slurry to obtain a concentrated slurry; controlling the density of the concentrated slurry to be 1.5g / cm 3 . Concentration treatment is carried out with a low-temperature decompression concentrator, and the temperature is controlled at 45°C-50°C.

[0067] Step 2: adding auxiliary materials to the concentrated slurry, blending and mixing to obtain a molding material liquid; the auxiliary materials include cyclodextrin; controlling the mass ratio of cyclodextrin to concentrated slurry to 1:35-40.

[0068] Step 3. Spray granulate the molding material liquid obtained in step 2 to obtain granular alfalfa solid beverage; wherein, in the process of spray granulation, add an edible fine-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com