Continuous light curing three-dimensional printing equipment and use method thereof

A three-dimensional printing and light curing technology, applied in the direction of additive processing, can solve the problems of deformation, easy bending and low elastic modulus in the polymerization inhibition zone, and achieve the effect of wide selection of materials, enhanced performance, and improved performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

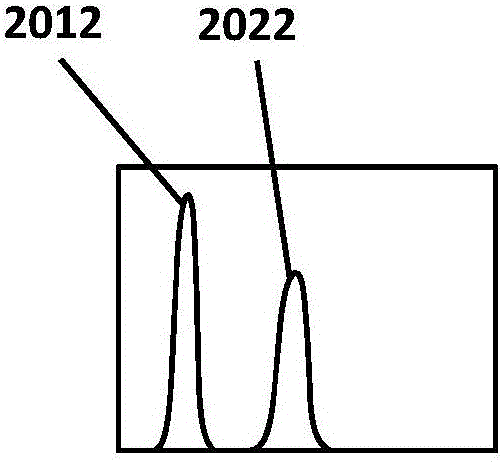

[0057] see Figure 6 , wherein there is a thin layer of liquid photosensitive resin 604 between the light-transmitting bottom plate 602 and the molding platform 605, and the photosensitive resin includes the following components: 100 parts by weight of lauryl acrylate, 100 parts by weight of tripropylene glycol diacrylate, 3 parts by weight of camphorquinone, 2 parts by weight Parts of N, N-ethylaminobenzoate, 6 parts by weight of tetraethylthiuram disulfide. Initiating light 601 with a wavelength of 470±5 nm passes through the light-transmitting bottom plate 602 and irradiates onto the photosensitive resin thin layer 604 . Due to the light absorption effect, the light intensity of the initiation light in the resin is curve 603 . In the wavelength range of the triggering light, the absorbance of the photoinitiator camphorquinone is much higher than the absorbance of the photoinhibitor tetraethylthiuram disulfide. After light, the camphorquinone is generated by the co-initiato...

Embodiment 2

[0059] see Figure 7 , wherein there is a thin layer of liquid photosensitive resin 704 between the light-transmitting bottom plate 702 and the forming platform 705, and the composition of the photosensitive resin is the same as that of Embodiment 1. Suppressed light 701 with a wavelength of 365±5 nm passes through the light-transmitting bottom plate 702 and irradiates onto the photosensitive resin thin layer 704 . Due to the light absorption effect, the light intensity of the suppressed light in the resin is curve 703 . In the range of suppressed light wavelengths, the absorbance of the photoinhibitor tetraethylthiuram disulfide is much higher than that of the photoinitiator camphorquinone. The rate of free radical polymerization initiated by itself is very low, while camphorquinone cannot be activated, thus unable to initiate the free radical polymerization process in the system. After irradiating for 10 seconds, the light source was turned off, and it was found that the p...

Embodiment 3

[0061] see Figure 8, wherein there is a thin layer of liquid photosensitive resin 807 between the light-transmitting bottom plate 803 and the forming platform 808, and the composition of the photosensitive resin is the same as that of Embodiment 1. The inducing light 801 with a wavelength of 470±5 nm and the inhibiting light 802 with a wavelength of 365±5 nm pass through the light-transmitting bottom plate 803 and irradiate onto the photosensitive resin thin layer 807 at the same time. Due to the light absorption effect, the light intensity of the initiating light in the resin is a curve 804 , the light intensity of the inhibiting light in the resin is a curve 805 , and the difference between the intensities of the inducing light and the inhibiting light is a curve 806 . In this embodiment, the photoinitiator camphorquinone and the photoinhibitor tetraethylthiuram disulfide are activated simultaneously. In the region close to the molding platform 808, due to the initiation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com