Method for online coating and preparation of diffusion polyester film

A diffused polyester film and coating technology, which is applied in the field of online coating to prepare diffused polyester film, can solve the problems of difficult and easy coordination of product thickness specifications, optical properties, film mechanical processing performance, and high cost of diffused polyester film. Wide range of selectivity and applicability, improve surface smoothness and gloss, and promote leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of online coating method of the present invention prepares the diffusion polyester film, carries out according to the following steps.

[0021] (1) Preparation of water-based coating solution.

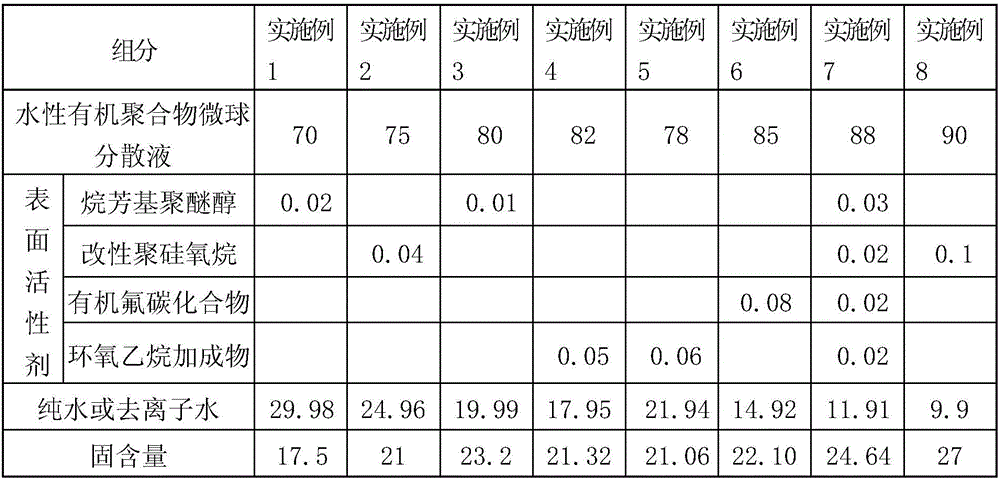

[0022] According to the mass percentage, slowly add 70-90% of the water-based organic polymer microsphere dispersion with different microsphere particle sizes into 9.9-29.99% pure water or deionized water and stir evenly, then add 0.01-0.1% surface The active agent is stirred evenly to prepare an aqueous coating solution with a solid content of 17.5-27% for use.

[0023] The water-based organic polymer microsphere dispersion of the present invention contains 25-30% polyurethane resin microspheres or polyacrylic acid resin microspheres, and the water-based organic polymer microsphere dispersion of the present invention can be commercially available containing 25-30% The water-based polyurethane resin of polyurethane resin microspheres, or the water-based polyacrylic resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com