Green composite fertilizer

A compound fertilizer and green technology, applied in urea compound fertilizer, inorganic fertilizer, ammonium salt fertilizer, etc., can solve the problems of no improvement of heavy metals in polluting components, insufficient improvement of soil fertility, soil degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

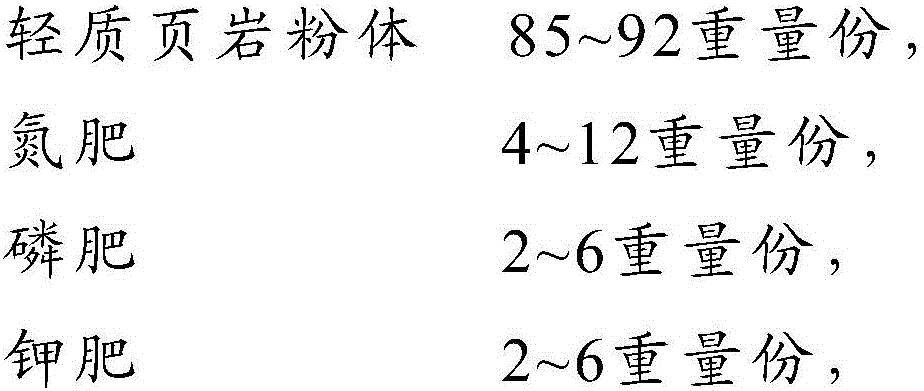

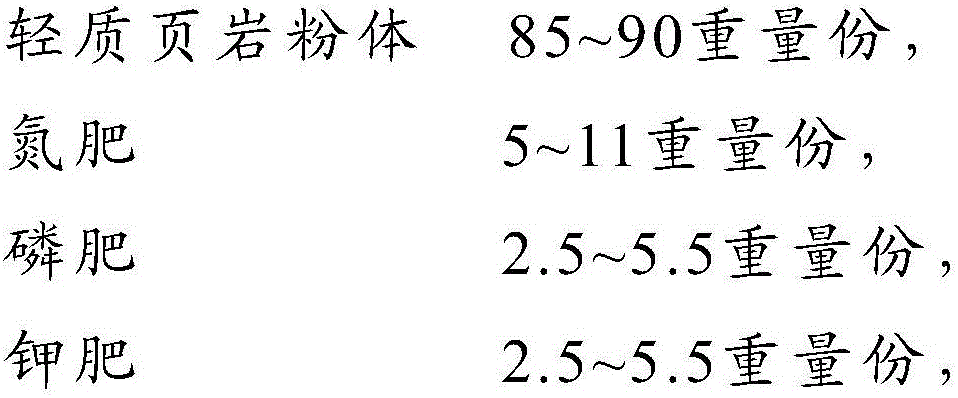

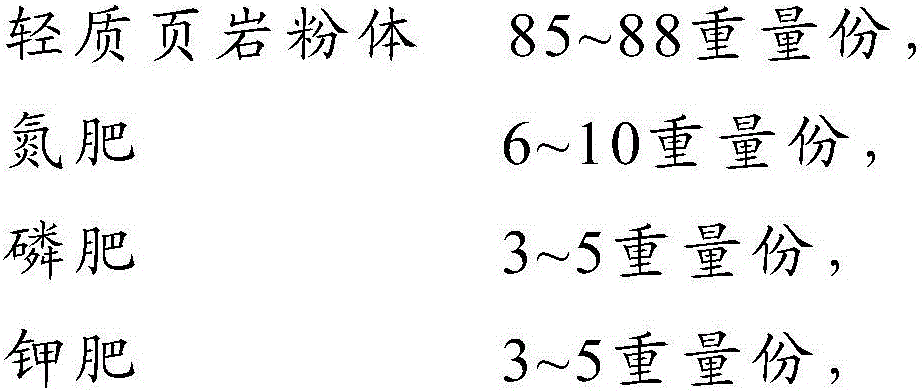

Method used

Image

Examples

Embodiment 1

[0097] Mix 850kg of light shale powder, 630kg of ammonium nitrate, 100kg of calcium phosphate, 38kg of potassium chloride and 150kg of water to obtain a mixture.

[0098] Put the above-mentioned mixture into an extruder for extrusion and granulation to obtain raw fertilizer granules, wherein the inlet temperature of the extruder is 200°C, and the outlet temperature is 60°C.

[0099] The obtained raw fertilizer particles are sequentially dried at 25°C, cooled at 5°C, and then sieved to obtain a green compound fertilizer.

[0100] Wherein, the obtained green compound fertilizer has smooth surface and uniform texture, and its average particle size is 3 mm.

Embodiment 2

[0102] Mix 850kg of light shale powder, 280kg of ammonium chloride, 95kg of superphosphate, 75kg of potassium Epsom salt, 20kg of potassium chloride and 100kg of water to obtain a mixture.

[0103] Put the above-mentioned mixture into an extruder for extrusion and granulation to obtain raw fertilizer granules, wherein the temperature at the inlet of the extruder is 220°C, and the temperature at the outlet is 65°C.

[0104] The obtained raw fertilizer particles are dried at 30°C in sequence, cooled at 5°C, and then sieved to obtain a green compound fertilizer.

[0105] Wherein, the obtained green compound fertilizer has smooth surface and uniform texture, and its average particle size is 2mm.

Embodiment 3

[0107] Mix 880kg of light shale powder, 130kg of urea, 150kg of phosphate rock powder, 300kg of plant ash and 80kg of water to obtain a mixture.

[0108]Put the above-mentioned mixture into an extruder for extrusion and granulation to obtain raw fertilizer granules, wherein the inlet temperature of the extruder is 250°C, and the outlet temperature is 70°C.

[0109] The obtained raw fertilizer particles are sequentially dried at 35° C., cooled at room temperature, and then sieved to obtain a green compound fertilizer.

[0110] The obtained green compound fertilizer has smooth surface and uniform texture, and its average particle diameter is 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com