Method for quick synthesis of zinc oxide whiskers by means of microwaves

A zinc oxide whisker and microwave synthesis technology, which is applied in the field of functional ceramics, can solve the problems affecting the market price and popularization and application of zinc oxide whisker products, which is not conducive to popularization and application, and the market fluctuates greatly, so as to reduce the whisker preparation process, The effect of reducing equipment investment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for rapidly synthesizing zinc oxide whiskers utilizing microwaves, comprising the steps of:

[0024] 1) Mixing treatment: Take iron (Fe) powder with a particle size of 53 microns and high-purity zinc oxide powder with a particle size of 1 micron (purity 99.0wt.%) as raw materials according to a molar ratio of 2:1, and then use a ball mill to mill Mix well for 5 hours, after ball milling, dry in an oven at 70°C to obtain dry powder;

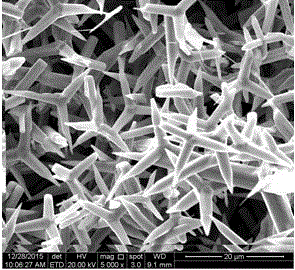

[0025] 2) Microwave synthesis: Put the dry powder obtained in step 1) into a quartz crucible, and place it in a microwave high-temperature furnace for microwave synthesis. The heating rate of the microwave high-temperature furnace is 300°C / min. The white flocculent product obtained after the furnace is cooled is tetraacicular zinc oxide powder (such as figure 1 shown), with a diameter of about 2 μm and a length of about 8 μm.

Embodiment 2

[0027] A method for rapidly synthesizing zinc oxide whiskers utilizing microwaves, comprising the steps of:

[0028] 1) Mixing treatment: Take titanium (Ti) powder with a particle size of 74 microns and high-purity zinc oxide powder with a particle size of 1 micron as raw materials at a molar ratio of 1.2:1, and then use a ball mill for 5 hours to fully mix them evenly. After ball milling, place in an oven and dry at 70°C to obtain dry powder;

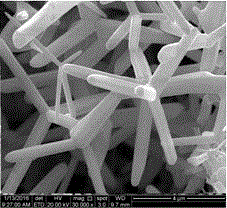

[0029] 2) Microwave synthesis: Put the dry powder obtained in step 1) into a quartz crucible, and place it in a microwave high-temperature furnace for microwave synthesis. The heating rate of the microwave high-temperature furnace is 350°C / min. The white flocculent product obtained after furnace cooling is needle-shaped zinc oxide powder (such as figure 2 and 3 shown), the diameter is about 0.2-0.5 μm, and the length is about 2-4 μm.

Embodiment 3

[0031] A method for rapidly synthesizing zinc oxide whiskers utilizing microwaves, comprising the steps of:

[0032] 1) Mixing treatment: Take manganese (Mn) powder with a particle size of 53 microns and high-purity zinc oxide powder with a particle size of 1 micron as raw materials according to a molar ratio of 1.5:1, and then use a ball mill for 5 hours to fully mix them evenly. After ball milling, place in an oven and dry at 70°C to obtain dry powder;

[0033] 2) Microwave synthesis: Put the dry powder obtained in step 1) into a quartz crucible, and place it in a microwave high-temperature furnace for microwave synthesis. The heating rate of the microwave high-temperature furnace is 300°C / min. The white flocculent product obtained after the furnace is cooled is tetraacicular zinc oxide powder (such as Figure 4 shown), with a diameter of about 0.2 μm and a length of about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com