Carbon nanotube fiber and method for producing same

A carbon nanotube fiber, carbon nanotube technology, applied in carbon nanotube fiber and its manufacture, in the field of manufacturing the carbon nanotube fiber, can solve problems such as poor operability and processability, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

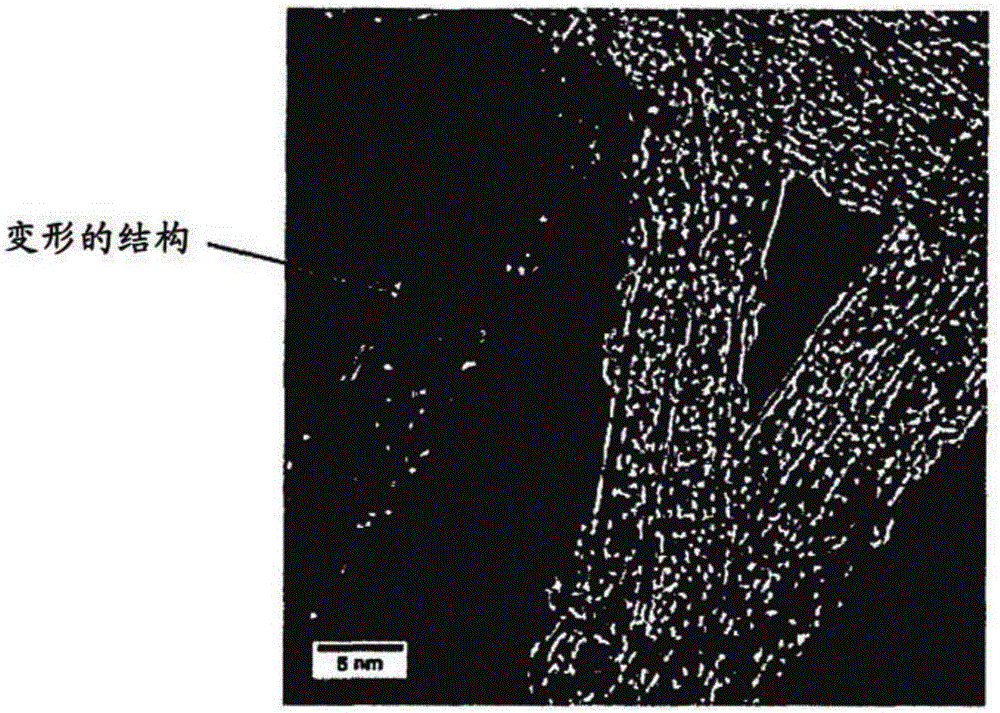

[0134] As the CNTs used in the preparation of the CNT dispersion liquid, the above-mentioned plurality of CNTs including deformed CNTs can be used.

[0135] [Dispersant]

[0136] In addition, the dispersant used in the preparation of the CNT dispersion liquid is not particularly limited as long as it can disperse CNT and can be dissolved in the solvent described below, and surfactants, synthetic polymers, or natural polymers can be used.

[0137] Here, examples of the surfactant include sodium dodecylsulfonate, sodium deoxycholate, sodium cholate, sodium dodecylbenzenesulfonate, and the like.

[0138] In addition, examples of synthetic polymers include polyether diol, polyester diol, polycarbonate diol, polyvinyl alcohol, partially saponified polyvinyl alcohol, acetoacetyl-modified polyvinyl alcohol, acetal-modified Non-toxic polyvinyl alcohol, butyral-based modified polyvinyl alcohol, silanol-based modified polyvinyl alcohol, ethylene-vinyl alcohol copolymer, ethylene-vinyl ...

Embodiment 1

[0176]

[0177] 1.9 g of aluminum tri-tert-butoxide as an aluminum compound was dissolved in 100 mL of 2-propanol as an organic solvent. Further, 0.9 g of triisopropanolamine was added and dissolved as a stabilizer to prepare a coating liquid A for forming a catalyst supporting layer.

[0178] Separately, 174 mg of iron acetate as an iron compound was dissolved in 100 mL of 2-propanol as an organic solvent. Furthermore, 190 mg of triisopropanolamine was added and dissolved as a stabilizer to prepare a coating liquid B for forming a catalyst layer.

[0179] On the surface of a Fe-Cr alloy SUS430 substrate (manufactured by JFE Steel Co., Ltd., 40mm×100mm, thickness 0.3mm, Cr 18%, arithmetic average roughness Ra≈0.59μm) as a base material, at room temperature 25°C, relative humidity 50 %, the above coating solution A was applied by dip coating. Specifically, after immersing the base material in the coating liquid A, the base material was held for 20 seconds, and the base mate...

Embodiment 2

[0189] When preparing carbon nanotube fibers, as a solvent containing a dispersant, instead of 500 mL of a 5% by mass aqueous solution of sodium deoxycholate (DOC), 500 mL of a 2.5% by mass aqueous solution of sodium deoxycholate (DOC) was used, and the amount of CNT1 added The CNT dispersion liquid 2 was produced by the same operation as Example 1 except that it was 2.5 g. Furthermore, CNT fibers were produced in the same manner as in Example 1 except that the CNT dispersion liquid 2 was used. Incidentally, the viscosity of the prepared CNT dispersion 2 was measured in the same manner as in Example 1, and the viscosity was 0.15 Pa·s. In addition, the density and tensile strength of the CNT single fiber 2 taken out from the produced CNT fiber were measured in the same manner as in Example 1. As a result, the density was 1.30 g / cm 3 , The tensile strength is 830MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com