Lithium ion secondary cell lithium cobaltate cathode material, manufacture method and application thereof

A technology of lithium ion battery and cathode material, applied in the field of lithium ion secondary battery, can solve the problems of poor cycle stability of lithium cobalt oxide cathode material, deterioration of cycle stability of lithium cobalt oxide cathode material and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

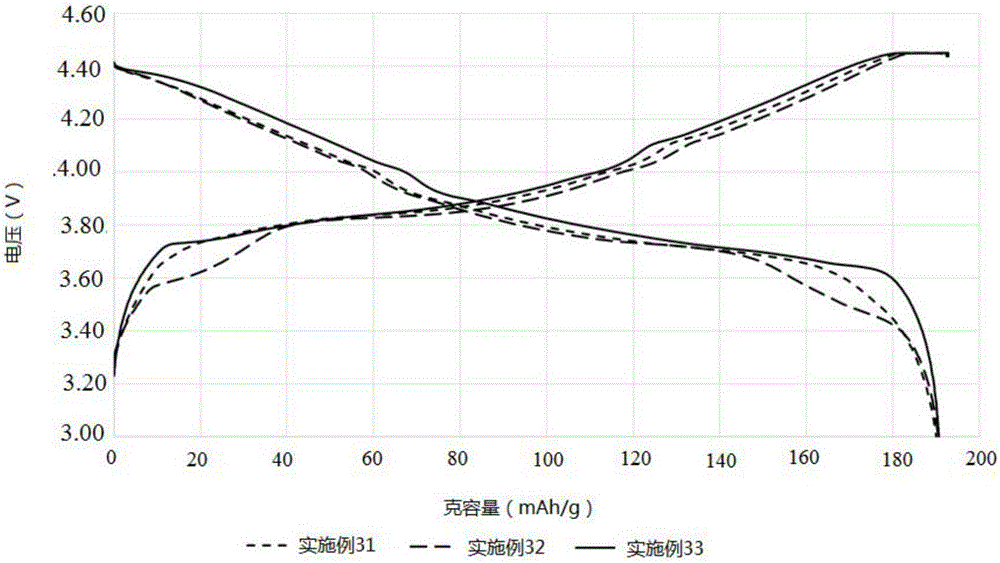

Embodiment 1

[0081] Example 1 Preparation of positive electrode material

[0082] The average expression with D50 of 25 μm is Li 1.11 co 0.98 al 0.02 o 2.055 The lithium cobalt oxide semi-finished product is used as the core material for coating.

[0083] The coating method is as follows: 1000g of deionized water is dropped into 7g of nickel acetate (containing tetra-crystal water), 15g of manganese acetate (containing di-crystal water), and a solid content of 10wt.% nano Y 2 o 3 Dispersion liquid 6.5g, stirred for 15min to completely dissolve the acetate, add 500g of core material, slowly drop in LiOH solution with a content of 5wt.%, control the dropping speed, gradually increase the pH value to 13 in 15 minutes, stop dripping Add LiOH solution, continue stirring for 30 minutes, filter out the liquid, dry the filtered material at 120°C for 10 hours, then use a muffle furnace to raise the temperature to 900°C at a rate of 8°C / min (25L / min air atmosphere), constant temperature sinter...

Embodiment 2

[0107] Example 2 Preparation of positive electrode material

[0108] The average expression using D50 of 5 μm is Li 1 co 0.98 Mg 0.02 o 1.99 The lithium cobalt oxide semi-finished product is used as the core material for coating.

[0109] The coating method is as follows: mix 1kg core material with 0.62g nano-NiCO 3 , 1.46g nanometer MnCO 3 , 0.33g Li 2 CO 3 , 1.27g nano-Y 2 o 3 and 1.67g nano TiO 2Put it into a ball mill for ball milling, so that various components are evenly coated on the surface of the core material, and then the material is heated to 900°C (25L / min air atmosphere) with a muffle furnace at a heating rate of 8°C / min, and sintered at a constant temperature for 24 hours , cooled naturally, and the lithium-poor coated lithium cobalt oxide cathode material was prepared.

[0110] Wherein, the preparation method of the core material is similar to the first embodiment, only the doping raw material is replaced with magnesium oxide, and the sintering tempe...

Embodiment 3

[0116] Example 3 Preparation of positive electrode material

[0117] The average expression for Li with a D50 of 20 μm 1.08 co 0.98 Zr 0.02 o 2.05 The lithium cobalt oxide semi-finished product is used as the core material for coating.

[0118] The coating method is as follows: mix 1kg core material with 6.2g nano-NiCO 3 , 14.6 g nanometer MnCO 3 , 3.3g Li 2 CO 3 , 1.89g nano-Al 2 o 3 , 1.67g nanometer MgO and 1.67g nanometer TiO 2 Put it into a ball mill for ball milling, so that various components are evenly coated on the surface of the core material, and then the material is heated to 950°C (25L / min air atmosphere) at a heating rate of 8°C / min in a muffle furnace, and sintered at a constant temperature for 4 hours , cooled naturally, and the lithium-poor coated lithium cobalt oxide cathode material was prepared.

[0119] Wherein, the preparation method of the core material is similar to the first embodiment, only the doping raw material is replaced with zirconia,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com